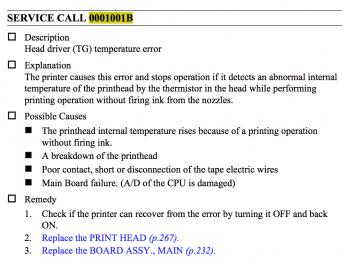

At risk of entering a realm I’m not too familiar with, I do know that those ribbon cables are extremely fragile. I’d check the condition of the exposed metal on the ends of the ribbon cables.

Larry

At risk of entering a realm I’m not too familiar with, I do know that those ribbon cables are extremely fragile. I’d check the condition of the exposed metal on the ends of the ribbon cables.

Larry

Extremely fragile! If they do not look perfect, they should be replaced. Generally, technicians usually do not replace ribbon cables with pre-existing cables but only with new cables for fear of shorting. These are not too expensive. I have shorted out our Roland by replacing a cable I removed that looked perfect. On closer inspection there was a very tiny fray in the contact edge - just a slight bend that then shorted out a $1,200 main board.  The cable was less than $30.

The cable was less than $30.

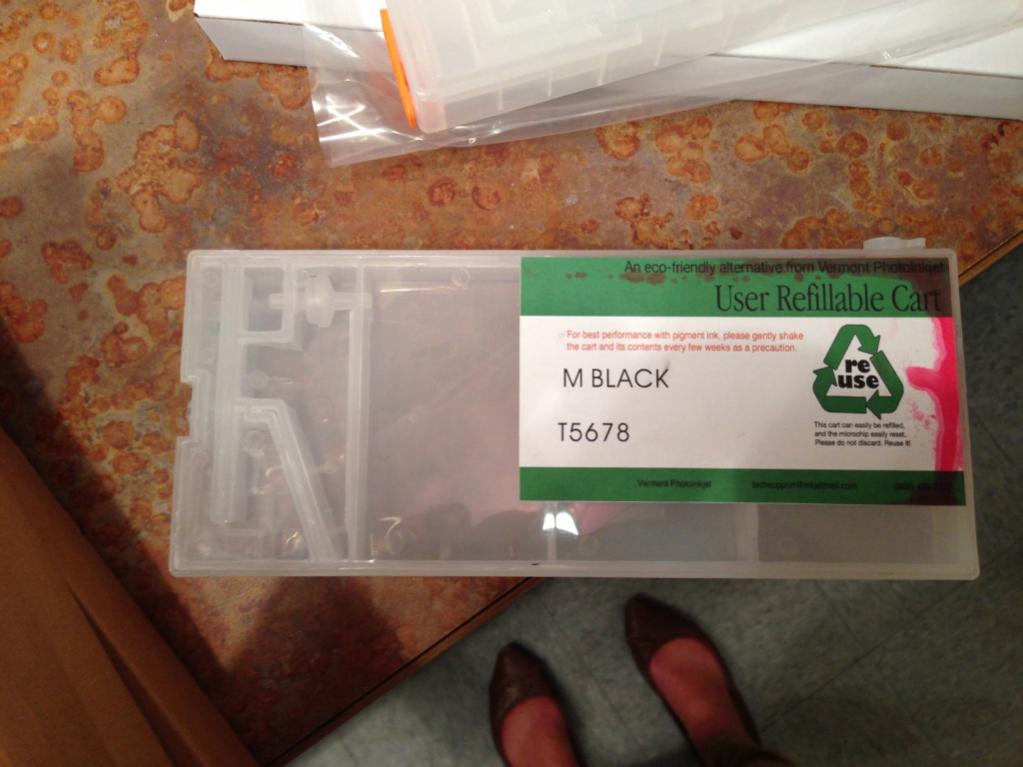

The error you’re getting is due to the print head temperature being too high, here is info about it from the repair manual:

Thanks for your input. The cable I put in was new, and looked perfect, but I will examine it again. I would like your advice on whether I should buy another cable to put in, or is it likely I have damaged the print head and need to look for a new one? I don’t want to buy a new print head, of course, but I’m this far into it now…

The end of the cable I replaced, which was attached to the print head, definitely showed damage, but I did not receive the error message until I replaced it. I replaced it with the new cable.

Hi it’s me again. Last night I removed the print head again to examine the cable connection. It is starting to exhibit a small amount of damage in the same area that was damaged on the cable i removed. I’ve attached two photos below, first the old cable and then the new. The third photo shows that when the new cable is inserted and removed there is again piezoflush in the connection, in the area of damage. Originally I had thought there was a leaky damper, but I thought that the leak was caused by the dampers being out of line, and that I had solved the problem by resetting them. Apparently there still is a leak, andI believe it is from the lt black damper. So I plan to replace that damper, and also get a new cable (again) since this one is already damaged. Hopefully that will repair the connection between print head and printer and I will be able to move forward. If not, I guess I will have to get a new print head also. Any advice is appreciated!

Best,

Abby

from my experience any moisture in a cable connection can or will fry the component up line from it. Two or more connectors short, and a small fuse will break. These fuses are soldered onto the boards to protect more expensive components. Print heads do not have protection with fuses.  The head board may but it is generating the signal and the damage tends to be upstream.

The head board may but it is generating the signal and the damage tends to be upstream.

The ideal situation of course is that there would not have been a leak. But there was and moisture made its way to a live circuit. So that factor may trump the leak (in that the head may be damaged.)

You are learning how to work on printers so you are an excellent candidate to get another X880 printer off someone else who has neither the time nor inclination to work on it. You are doing dig neg and do not need 8 working channels. can you find a give away printer with a permanently clogged ink channel? You might harvest that head for your printer and we can show you how to re-write the Piezography Curves to map out the bad channels. Technically you need only 5 working channels for what you are doing, right? Dig neg does not use shade 1 black - it only uses 2, 2.5, 3, 4.5, & 5. So a head with only 5 working channels while useless to anyone else would be valuable to you. I might harvest the boards and cables as well. Rebuild your printer - or better yet. Work off the new printer and keep yours for parts… ? All trying to get you to avoid buying a refurbished X880. But if you do buy one - buy from Ron Arditos. He’s builds them well.

Sort of saying that you may have gone past what you can do for this printer right now.

However with one last gallant effort on your part. STOP THE LEAKS. that is primary. Clean and then dry the cables perfectly clean with alcohol. Flush out the receivers for the connectors with distilled followed by alcohol to clean the moisture and piezo chemistry from these points. Then perfectly dry them. When everything is perfectly dry. Reconnect everything - initialize with ink or flush. Check and see if the print head operates. The error may be due to active shorting from the moisture rather than a damaging short that has made something in the head permanently fried. Am I making sense? I realize this is a bit rambling.

Jon,

Thanks. I have been afraid that I might have created a problem that is too much to fix, but I will give it the one last gallant effort, at the least.

So from your message I understand it is perhaps better to look for another 9800 printer than to buy a new print head, unless after stopping the leak and removing all the moisture things come back to normal. Everything was going so well until I replaced the dampers!

Thanks for all your help,

Abby

Jon,

Thanks for your reply. I have had the feeling that I may have created a problem that is too big for me to fix… it was all going so well until I replaced the dampers

But I will give it one last gallant effort, at least, buy stopping the leak and drying everything out one more time.

From what you are saying, I should probably start looking for another 9800, instead of continuing to buy parts for this one. It’s too bad, but still worth it.

Thanks again, I’ll let you know how it turns out. Please let me know if you have any more thoughts.

Abby

Hi,

I’ve been occupied by other things for the past few days but am going to take Jon’s advice and make one last effort to stop the leak, replace the cable again, and try the printer one more time. In order to dry out the printer, is it recommended to leave the print head unattached for a little while to dry it out, or is this bad for the print head? I was planning to take everything apart to dry it carefully, replace the damper i suspect of leaking, and leave things to dry out for a little while before starting up the printer again. Please let me know,

Thanks, and happy holidays!

Abby

Abby,

i would not let the head dry out. I was referring to the contact points where the ribbons connect. Your ribbon cable got wet and the pics show that these contacts were wet too.

Hi,

I hope you had a great holiday over there! With some help, I have a new print head in the 9800 and am ready to install the Meth 1 inks. I just want to confirm that I know which inks go in which cartridges, since the instruction sheet references the K7 inks. Can you please send me a quick list of which inks go in which cartridge? Thanks so much,

Abby

Hi Abby~

I’m glad to hear your printer is up and running again, and hope you had a great holiday as well

Piezography ink shade placement charts can be found here: http://www.inkjetmall.com/tech/content.php?171-Piezography-K7-P2-and-Digital-Negative-Curves-and-Ink-Placement-Charts

To setup your 9800 with Meth 1, you will want to follow the top chart, under the first column titled PZDN-Meth1.

Best regards and happy printing~ Dana

Thanks so much!

Hi Dana,

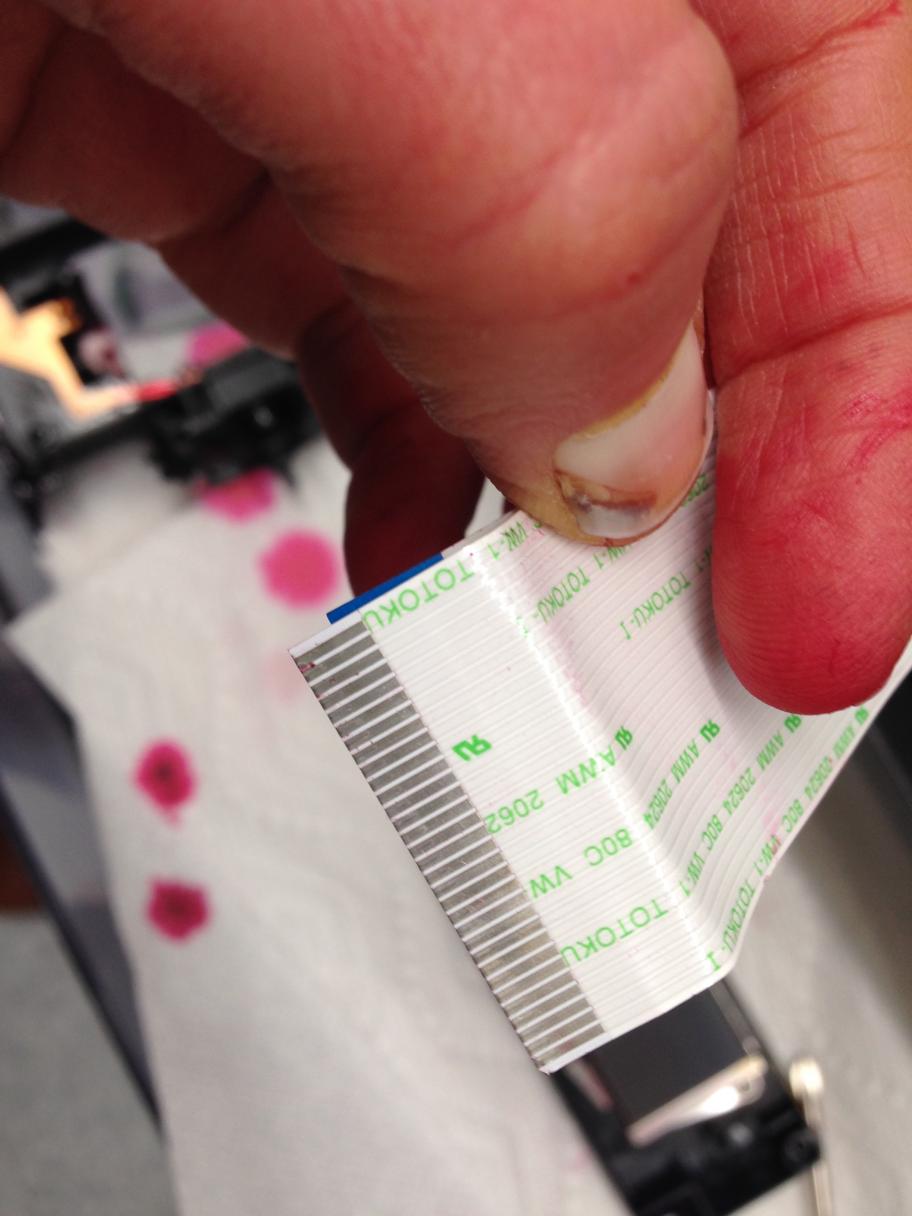

Another question! Before the holidays I ordered new cartridges for the inks. I didn’t open them all up until today… the Magenta cartridge (1st photo below) is different than all the others (2nd photo below). I’m not sure if there was a mistake with the order, or you guys are switching over to another cartridge type…

It is marked for use with the 9800… can I go ahead and use it with all the others, or do I need to empty out the M cartridge from my set full of piezoflush and use that one instead? Thanks for your help,

Abby

Please don’t use the different style magenta cart (we received some of this style in error), and I will have a replacement sent to you right away.

Best~ Dana

Thanks so much Dana,

Abby

Can you please let me know when the replacement cart is shipped, and when we can expect it?

Thanks,

Abby

I’ll get your replacement cart out in today’s mail via Priority Mail, so you should receive in about two days.

~Dana

Thanks again!