Any thoughts on cause for banding when I get a good nozzle check pattern.

The banding show up right at the start of printing an image but provides a good pattern

before and and after printing. It’s 9890 printer

Hi Brian, Thanks for the info on nozzle pattern checking. Altho I have yet to find the path to perform a MANUAL nozzle check pattern on a 9890. I am familiar with the 9800 but can’t find it in any schedule of the 9890.

With that, I have done all the recommended cleaning; flushing, nesting and squeege elements as well as a CL3 cleaning cycle with no change to the banding in the LC.

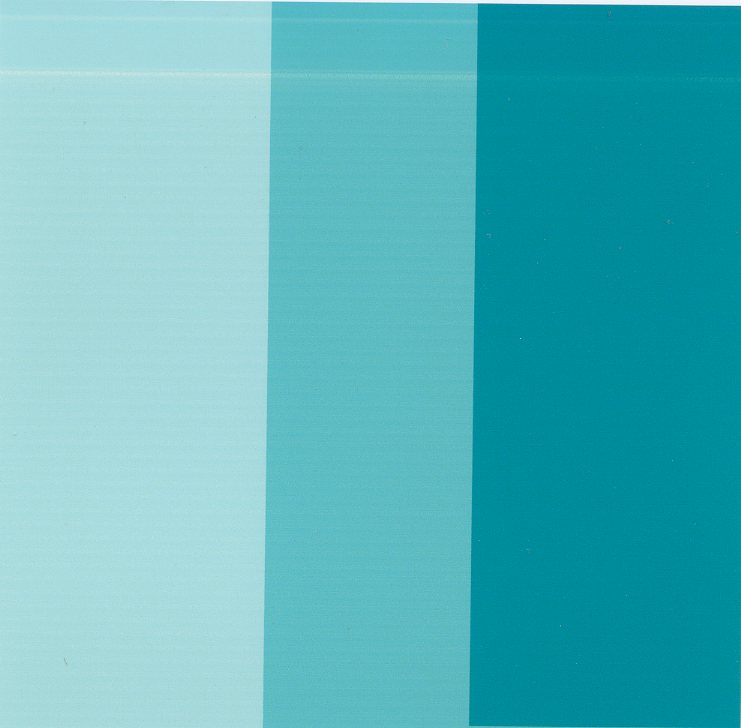

I will include a scanned pattern of banding. The scan is a cyan patch with a zone 7,5,3 densities. Through this I determined that the problem is with the LC as the zone 3 patch has minimal banding compared to the zone 7.

What I find curious (mostly annoying) is the way it has a significant band at the beginning and then goes to the regular banding. This pattern is exactly the same for numerous printings. Just a little history…this is the third head in this printer, it will not see another. The printer is about 6 years with me new and from day one has had cone color pro inks through the print head. I know your familiar with the endless conversation I’ve had with Epson which remarkable they covered the cost of the third as a “curtesy” as I have owned over 10 Epsons.

There you have it, see if this scan gives you any clues as to whether I have a dead nozzle. If so I’ll go to my 9600 that still kicks butt. One last thought…what is the possibilities of filling 9600 carts with K3 inks.

Thanks

Nozzle check (as I recall):

On control panal:

Right Arrow, Down Arrow, Right Arrow, Right Arrow, Right Arrow, Enter.

This model printer goes through heads every 2 years on average. Sometimes quicker, sometimes longer. It doesn’t matter the type of color ink used. Piezography ink does not kill these heads.

best,

Walker

I take it from your response that the nozzle is damaged and the head dead. Your right with the menu for the 9890 nozzle check (you have one extra right arrow) but that does not provide the extended pattern the 7800/9800 offers in manual mode.

Looks like this 9890 will be finding a home in recycle center.

Thanks for you attention

Russell

If you post the nozzle check I can tell from it if the nozzles are burned or not.

From the patches that you uploaded, it does look to be the case, but this would be informative for others who want to know how to read these things.

We get nozzle checks about 3 times a day from customers who have OEM inks and heads that have burned out. Often we can save the head with Piezoflush but we like to see the nozzle check first so we can determine for the customer if it’s worth a flushing (just a clog) or if it’s nozzle-burn (de-lamination) of the head.

Best,

Walker

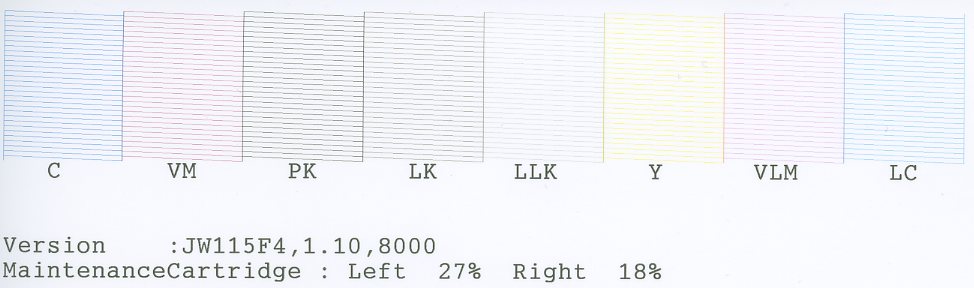

Here’s a nozzle check pattern from the 9890, as you can see the LC looks like all is good but as you can see from the previous scan I sent it has banding issues. This is the only nozzle check I can find to do from my 9890, I have looked everywhere, in the maintenance menu, reg. menu and referred to my pdf service manual for 9890 but no manual nozzle check to be found. Hope this scan can give us some guidance. If you need a more detailed scan let know know and I’ll zoom in on the pattern or if you can find a way to a more comprehensive nozzle check I’ll

print one out.

Thanks again for your help

Russell

Hey Russel. This problem (good nozzle check bad start of print) has cropped up a few times on the Epson Wide Format forum. EpsonWideFormat@groups.io | Home

It is generally fixed by replacing the print-head as it’s a sign of a pre-failed head (aka, you are getting fire delays that only really show in the first inch of the print while the paper isn’t advancing and the micro-weave is different.)

You may want to go there and do some searching though as some have had luck replacing the head board, cable, and/or motherboard (mainboard).

-Walker

Hi Walker, I joined and checked out the Epson Wide Format forum you suggested and it does on the most part confirm things are going south with this head.The one thing I have since discovered is that the configuration of inks for gray scale are not reliant on the LC, so for now I am printing up a batch of B&W’s old work as all my work from the past 30 yrs is color…I had been wondering about the new generation of Epson P6000 P7000, and noticed in the forum you mentioned a steady list of head clogging, so I think I’ll stay away from the new generation of Epson for now. For now I will work with my old but steady 9600. I lucked out and bought this printer a couple of years ago for $400 which included three full sets of 220ml carts of Epson inks. When those run out I will be converting to the Cone Color Pro ink set. I had posed the question earlier if there might be some logic to fill 9600 carts with 9800 or 9890 K3 inks. I create my own profiles and thought I could deal with the differences. I have noticed that the Epson inks for the 9600 have issues with metamerism not occurring with the 9890 ink set. Thanks for all your attention and direction in helping with this issue.BestRussell

Russell Phillips Photographywww.rphillipsphoto.com

walkerblackwell

September 10 |

Hey Russel. This problem (good nozzle check bad start of print) has cropped up a few times on the Epson Wide Format forum. https://groups.io/g/EpsonWideFormatIt is generally fixed by replacing the print-head as it’s a sign of a pre-failed head (aka, you are getting fire delays that only really show in the first inch of the print while the paper isn’t advancing and the micro-weave is different.)You may want to go there and do some searching though as some have had luck replacing the head board, cable, and/or motherboard (mainboard).-Walker Visit Topic or reply to this email to respond.

In Reply To

Russell InkjetMall Customer

September 8 |

[nozzle pattern075] Here’s a nozzle check pattern from the 9890, as you can see the LC looks like all is good but as you can see from the previous scan I sent it has banding issues. This is the only nozzle check I can find to do from my 9890, I have looked everywhere, in the maintenance menu, reg… Visit Topic or reply to this email to respond. To unsubscribe from these emails, click here.

I suggest using the K3Vivid inkset for the 9600 (except the black inks) but use the LK black ink that is set for the 9600 and then either HD-PK or Ultra-HD-MK for the blackest ink.

This will give you the ultimate 9600 inkset.

best,

Walker

HI Walker

I have recently just installed my first refill cart in my 9600. I noticed when setting the cart it did not lock into place as it should before resetting the lever to lock position. When I hold the cart in and lock the lever the cart is locked. This cart replaced a Epson cart for LM. I also noticed that when I pull the cart out of the slot there is an air bubble at exit port. I did prime with syringe prior to install. Tried re priming and when I pull the cart out there is air at port exit. I bring all this up because shortly after inserting the refill LM cart I lost all ink from that nozzle. I have done numerous cleanings with no change. Could the cart be the problem. I am thinking I could swap the chip from my LM cart with my MK cart and fill the new cart with LM ink to see if that works.

Swap in the MK cart/chip. I think. This will tell you if it’s the cartridge or ink bay. Always good to have extra carts no matter what.

-Walker

I just began experiencing a similar issue with my black ink on my Epson Stylus Pro 9890

I bought it new 6 years ago and it has been working most of the time without issue. I have had banding before but a power cleaning usually did the trick. This time it keeps coming back. I do a Pair Cleaning on the PK/LLK which clears it up but then a couple of feet later it starts again, first with a large band then back to the lines

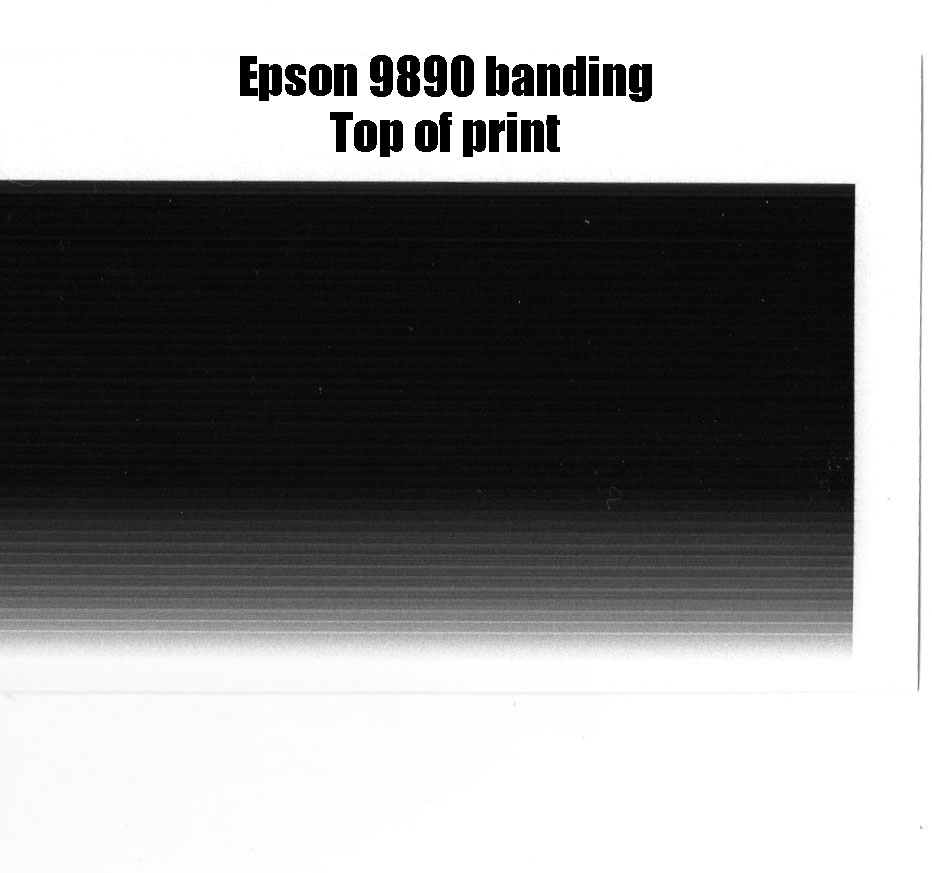

Here is another look at it from a black test I canceled before it completed

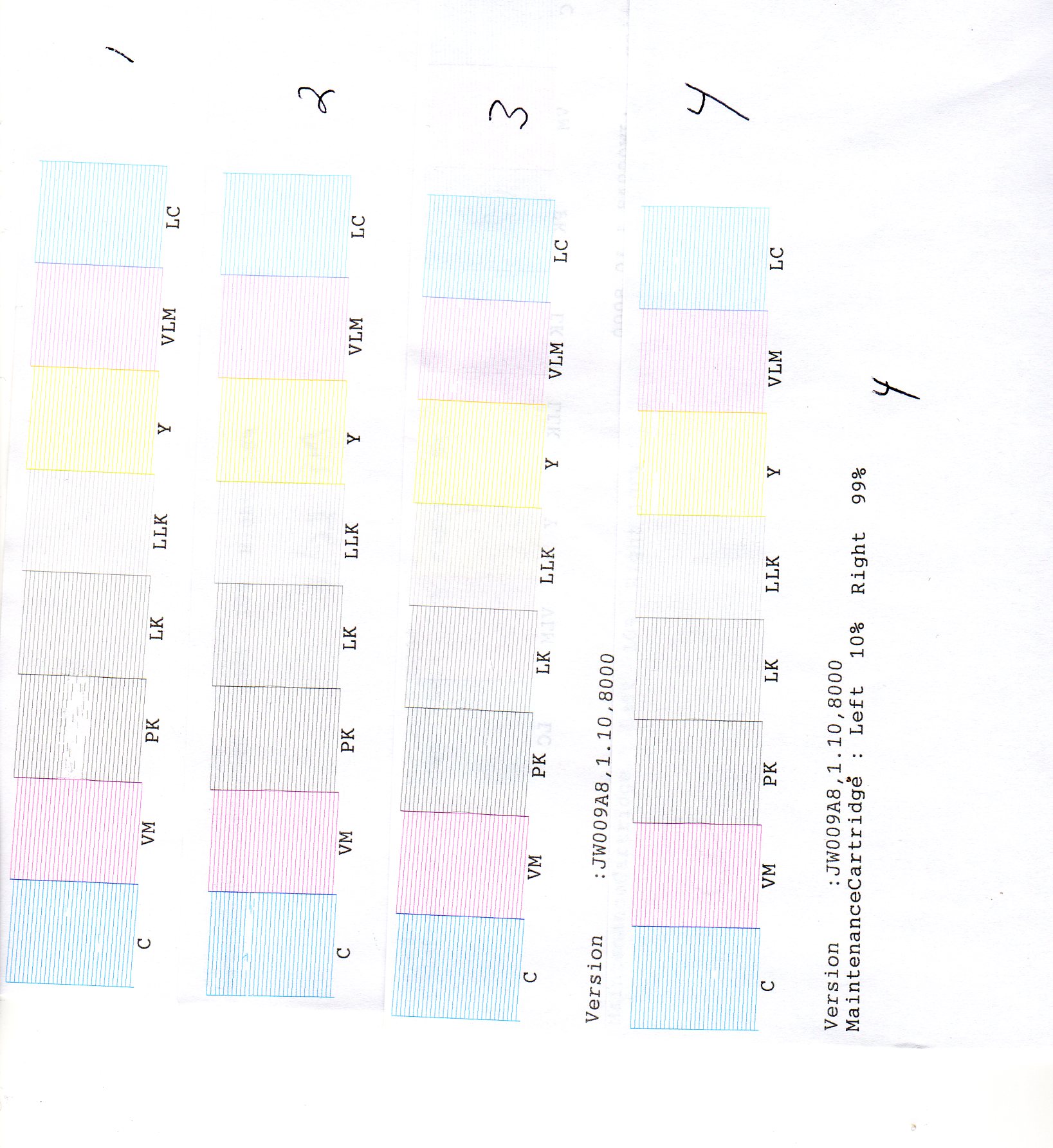

Here are the subsequent nozzle checks. Check 1 showed a significant PK issue and a small Cyan issue but after a Power Cleaning, but the banding persisted. I did a shoe shine (cradel Rock) cleaning with PiezoFlushe the nozel check, Check 2, showed the PK good but the cyan looked bad another Power cleaning and the Cyan was resolved as well check 3. I got a couple of good prints out and then banding restarted I did the Pair Cleaning got a couple more prints out and it started again Check 4 shows what it looks like now and it is still banding Top image

Should I do a full piezoflush or is this printer head gone?

Thanks for any advice

This is a combo problem. Both the cleaning assembly is going (full of crud and old motor) and your PK channel is going. The easiest way to tell if a channel is de-laminating is the middle bowing of the nozzle check (you can see this on the PK) and frequent drop-out of the middle (first).

This head will probably not last more than another few weeks on the PK channel. The cyan channel may be going too but not sure. Could just be a clog.

PF is for clogs, not delaminated print-heads.

best,

Walker

Hi Walker

Thanks. I’m going to convert this unit into one of your Piezography inksets. I saw you had one that did negatives as well as prints. Is that possible with this machine? Also any feedback on the new SureColor printers. I just ordered a P9000 CE and P10,K printer for the college where I run another studio for the students there. I already turned their old 9800 into Piezography . Working very well I may add.

Hi Walker my new P9000 just arrived and I am hoping to turn my old 9890 into a Piezography printer. Is that possible with a de-laminated PK channel?

It’s possible although you are limited to Matte only Pro/K7/K6 printing. for Pro you would get the Matte set for the 9890 (no GCO or PK ink) and put the Matte Black in the LLK position and then remap your curves.

best,

Walker