Dana - I am using an Epson 7900, using windows and the ink set that includes both matte and glossy.

Question 1 - I downloaded QTR 2.7.2 as directed. When I opened the QTR program it showed that I was using version 2.7.0. Why is that? Is it Ok to use 2.7.0 with with a 7900 and the 7900 profiles? If it is not, how should I override the newest version over the older version?

Question 2 - I happened to notice that the QTR program now has version 2.7.5 available. Should I update, why or why not?

Question 3 - A glossy profile for the 7900 is entitled 7900-MPS-K7- CansonBarytaSatin. Is this the same paper as Baryta Photographique? If it is not, what is the Canson paper to be used with this profile?

Question 4 - Assume the following: Printing an image on Type 5 paper using a 7900. In the media box under Type, should I choose Photo or Matte paper? Under black ink, do I choose photo black ink or is it automatically selected? The 7900 printer has series of paper types that show up before printing. Which type of paper should I choose?

Question 5 - Assume I am printing on Type 2 paper. In the media box under Type, should I choose Photo or Matte paper? Under black ink, do I choose photo black ink or is it automatically selected? The 7900 printer has series of paper types that show up before printing. Which type of paper should I choose?

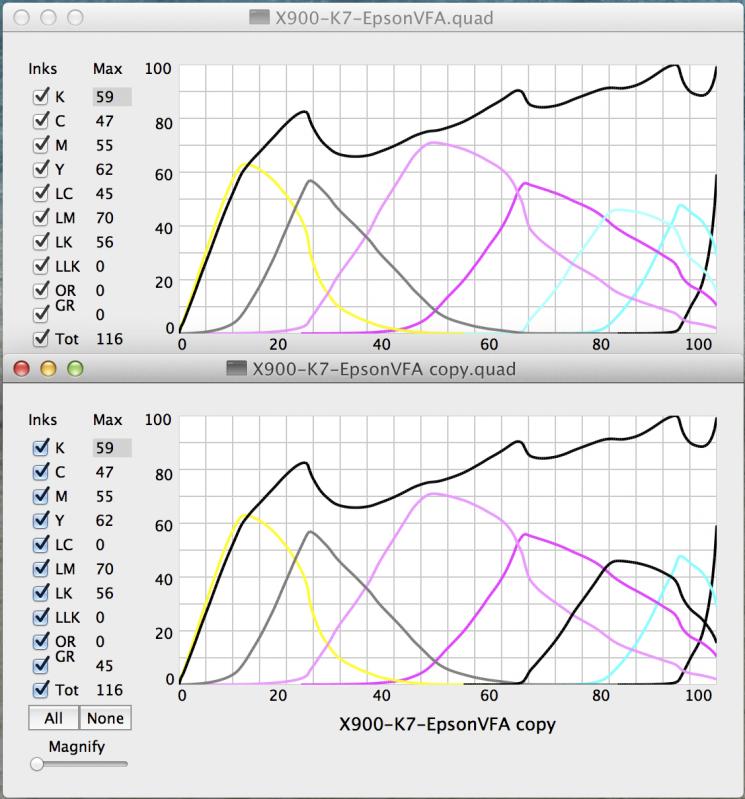

Question 5 - It’s a question based upon a lament. I was having a difficult time removing the yellow tinge in ink 7. I then moved the head and inserted a piece of folded paper towel with a wetting of flushing solution. When I was moving the head back and forth the paper towel got stuck. Fortunately, I was able to remove it and the yellow ink tinge has disappeared. The unfortunate thing is the light cyan nozzles. which worked fine before, are mostly clogged. Subsequent cleanings have done nothing to correct the problem? Approximately 50% of the nozzles continue to remain lost. I have done the extra powerful cleanings for the light cyan channel and have had no luck correcting the problem. In fact, I don’t see any change in the problem nozzles. Can it be corrected? If so, how? Or do we need to be in contact to change one of the flushing channels into a light 7 channel?

Thank you for your assistance.

Steve