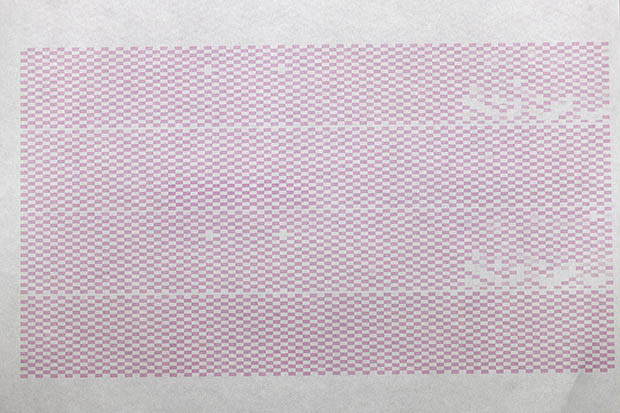

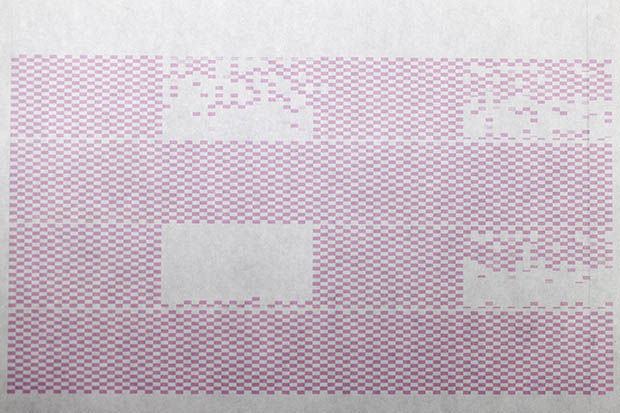

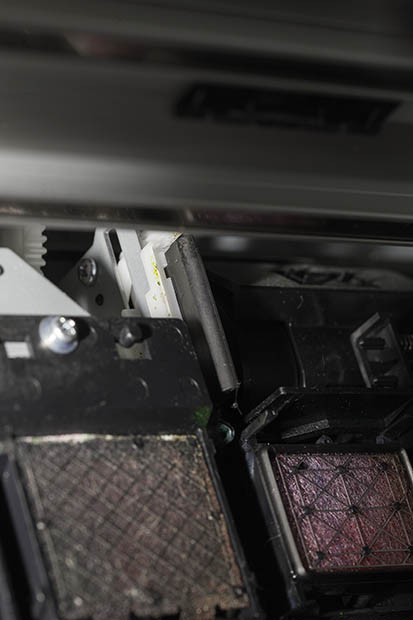

I am trying to resurrect a 7800 and having some luck but also having some issues. The printer had not been used for quite a while before I picked it up. I have installed a set of carts filled with Piezoflush and did an initial fill. All lines flushed out the old ink and air bubbles that were in them, I let it sit for 3 or 4 days then did a nozzle check. The first half of the nozzle check went relatively well, sometimes it did an auto clean before moving on. The 2nd half of the nozzle check is where I am running into problems, The 2nd section which I am assuming is Cyan was missing a few sections the 4th section which I’m assuming is Yellow was printing 70-80%. I ordered a new set of dampers and installed them tonight. I used the syringe and priming tip in the port that goes onto the head to draw Piezoflush into the damper. The nozzle check shows the 2nd section has stopped almost completely, the Piezoflush is barely perceptible. The 4th section is printing about 70% with sections missing but prints they are as strong as any of the good sections. The capping station, flushing box and wiper have all been cleaned. The Magenta cart I received from IJM is different than any of the other carts I got in the same order, it is about an inch longer than the others. In another post on the forum somebody else had the same situation and was told not to use the cart, it was shipped in error and should be swapped. Is this the case with my cart as well? Any help you could offer is greatly appreciated. Thanks. The first photo shows the nozzle check before changing dampers the second is after changing the dampers. The third photo shows condition of the capping station, flushing box and wiper all of which are original to the printer which has had only one partial set of inks put through them since new.

I reinstalled the carts after adding Piezoflush and then checked the Cyan and it did have pressure. It just doesn’t seem to hold the pressure as long as the others.

That waste pad on the left is almost entirely full of crud. You need to piezo-flush it directly and order a replacement from CompassMicro as well.

<edit out> damper comment, I see you replaced yours </>

Wells is sending you something re: damper shortly. Check email.

If it was cart-related, you would see back-pressure zooping up the line from the print-head after a clean. Sharpie your cart levels before you do either an init-fill or maint-clean and then you can see the carts that perform well and those that don’t.

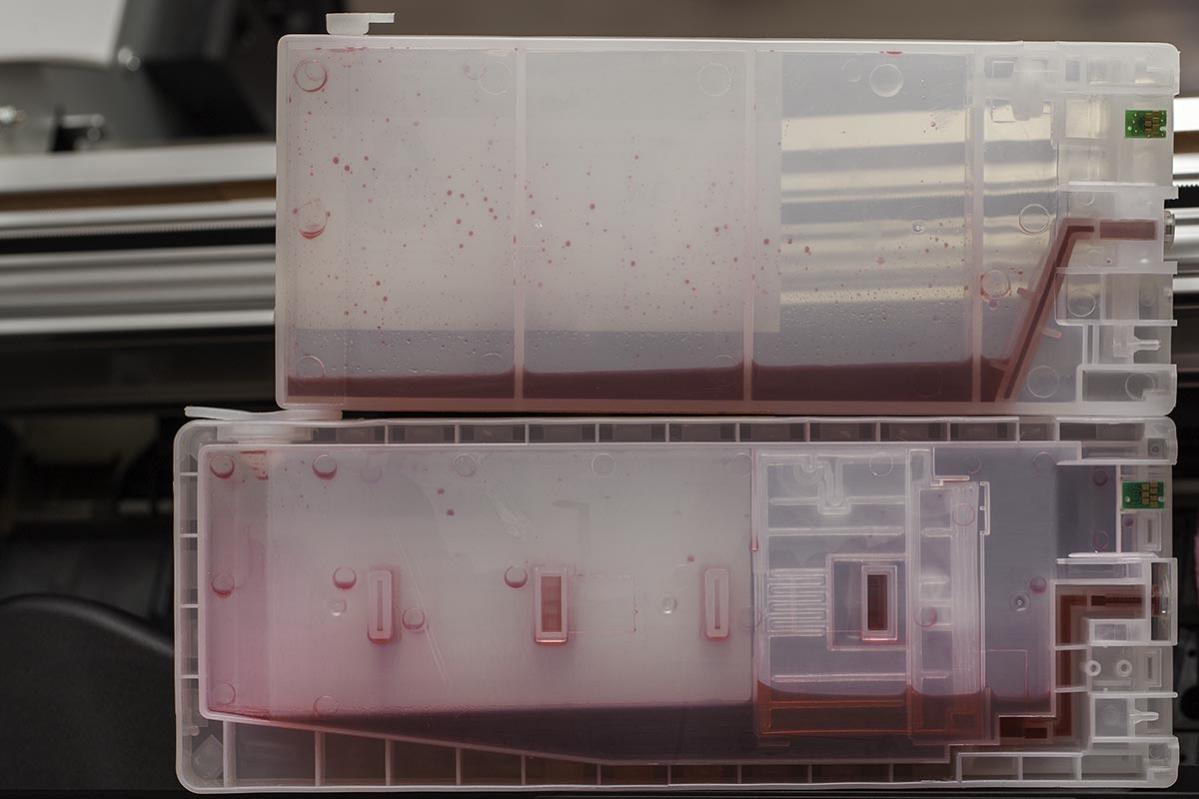

/// EDIT> Re magenta cart. Can you send us a photo of it vs the other ones you have? Also, like Dana said, don’t use it. We are working on debugging some x800 related issues. support at inkjetmall dot com

regards!

Walker

Also, I would switch to manual-check for the nozzles. This way it’s much easier to see and a quicker read and it won’t constantly be doing single cleanings.

Here is the picture of the two different carts. 7 of the carts are like the top cart the one on the bottom is the Magenta cart.

After doing an initial fill the Cyan and Yellow were the two colors that were causing the most problems. The Cyan feed line never turned the same color as the other lines with Piezoflush in them, it was a darker purple color. I took the right end cover off to clean the capping/flushing stations and wiper better. With the ink lever lowered the Cyan line emptied itself through the printhead onto a paper towel that was under the head to clean the face of the printhead. I also noticed under the port in the black cart bay the white felt was stained by Piezoflush. Do you have any idea what the cause of this leak would be?

Pressure is building up in the cyan cart during mutli-cycle init fill (all carts a pressured at the same time but that one isn’t able to let off pressure) because the Piezoflush can’t get through it has nowhere to go . . . ![]() Because it emptied through the head when it was released from the capping, it looks to me like the capping/cleaning assymbly is still funky. But because the other channels went fine, jeez. Too many variables. Not sure.

Because it emptied through the head when it was released from the capping, it looks to me like the capping/cleaning assymbly is still funky. But because the other channels went fine, jeez. Too many variables. Not sure.

It may be time to simply run some prints on cyan and see. Others cleared good ![]()

W

All off the lines from the right side have drained themselves to one degree or another overnight, except the magenta line which is completely filled with PF. None of the lines were pressurized, the carts were removed to take off the printer’s end cover. The ink lever was lowered. The cyan line drained fast enough that it could be visually tracked. The photo black line is nearly empty and the yellow line is about half empty.

We’re going to send you another magenta cart when we can work on some out-of-stock issues here. Rest assured, we got your back. Might take a little bit of time.

regards,

Walker