I’ve replaced the Eboni inks in my old cartridges with MIS Nozzle Cleaning Fluid (as much as I have left). What remains in the cartridges is a mixture of ink and cleaning fluid. The old cartridges are still in the printer.

I’m printing purge images and running the 2Manuals adjwiz2.exe to draw the remaining material out of the printer. There is still some density when I print a QTR Ink Pattern Page.

I purchased 2 sets of cartridges: one for ink, another for PiezoFlush. At what point should I install new cartridges ? Should they be filled with ink or PiezoFlush ?

Many thanks. I look forward to using the K7 inks !

Dear Ken. The new carts should be filled with K7 and purged into the system with the adjwiz.

The other set of carts should be stored safely empty as backups and spares w/ the Piezoflush bottle.

We originally printed your target with a high-end carbon P2 curve. New and old curves will be available for this printer soon at the re-launched Piezography.com website but in the interim I can email you the new set of lin’d curves.

For best results, a custom 256-patch K7 linearization can be done by us as well. (Every printer is slightly different.)

regards,

Walker

That was fast ! Thank you !

I’m confused about the P2 curve: is that a new curve, a new ink, or both ? Please email me the new set of curves. Once I get up and running I’ll proceed with getting a 256-patch K7 linearization.

The P2 curve is a K6 curve.

-Walker

I got all the way through installing new cartridges and completed my first power-clean. Now the printer is requiring me to replace the maintenance cart.

I’ve watched this video: InkjetMall 3880 3880 maintenance tank resetter. It says “A full tank cannot be reset”.

How can I determine whether my maintenance tank is really full and therefore unable to be reset ?

Do I need to purchase 2 new maintenance tanks and a chip resetter, or what please ?

Thank you !

When the printer requires a new maintenance cart, the maintenance cart is full.

This can happen when an init fill takes place. You need a new maintenance cart. With this new one (during normal printing) clean out, pad, and reset the cart at about 15% left.

regards,

Walker

I’ve replaced and reset the maintenance tank. I’m now making prints.  I’m thoroughly delighted with your support and instructional materials !

I’m thoroughly delighted with your support and instructional materials !

Could you please email me the profiles you mentioned in post # 2 above ?

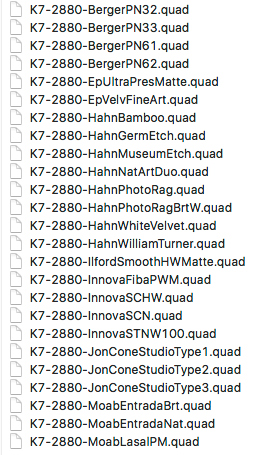

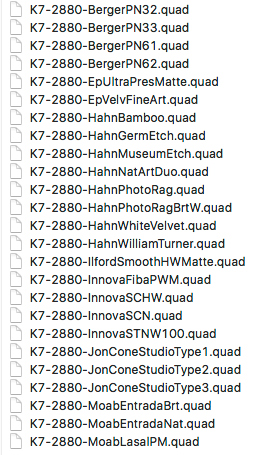

Is the Epson Ultra Presentation Matte mentioned in the list below (the K7 3880 profiles which ship with QTR), the same as Epson Premium Presentation MATTE ?

Previously I used 2 papers whose profiles are not shipped with the QTR download (see above), namely Premier Smooth Hot Press Fine Art and Epson Hot Press Natural. They are both 100% rag papers with no OBAs. Are profiles available for those ? Do they match any of the above-listed papers ?

Many thanks !!

Here are the updated P2 curves. Note: the PK channel has been mapped to the Yellow channel. If your PK is in the traditional place you’ll need to map it back. A quick google search of this forum will bring up the documentation for that.

http://piezography.com/3800-3880-P2.zip

http://piezography.com/3880-New-K7.zip

best,

Walker

Sorry, I’m confused. According to Piezography 2 Matte and Gloss for K3 printer models,

"Piezography 2 is designed for use with the K3 8-ink Epson printer models, such as the R2400, R2880, 4800, 4800, 7800/9800 and 7880/9880.

*If using a R3000, 3800/3880, 7890/9890 or 7900/9900 printer that has two black channels, P2 isn’t necessary, because matte and gloss printing is already possible with K7. "

I have a 3880 and just purchased and loaded K7 inks. I intend to make matte prints only. Do I need - or should I transition over to P2 inks ?

Apparently the 3880-New-K7.zip file contains profiles for new paper/ink combinations such as SEL for selenium, SpecEd for Special Edition etc. Am I right that the new profiles aren’t replacements for the profiles which ship with Quadtone RIP, just additional papers/inks ?

[QUOTE=Kenneth Lee;11760]Sorry, I’m confused. According to Piezography 2 Matte and Gloss for K3 printer models,

"Piezography 2 is designed for use with the K3 8-ink Epson printer models, such as the R2400, R2880, 4800, 4800, 7800/9800 and 7880/9880.

*If using a R3000, 3800/3880, 7890/9890 or 7900/9900 printer that has two black channels, P2 isn’t necessary, because matte and gloss printing is already possible with K7. "

I have a 3880 and just purchased and loaded K7 inks. I intend to make matte prints only. Do I need - or should I transition over to P2 inks ? [/QUOTE]

I’ve always had trouble with that statement on the IJM P2 page, because “it isn’t necessary” sometimes gets interpreted / portrayed as “you shouldn’t”. Which is odd, given that my understanding is that IJM runs P2 in its 3880s in the Piezography workshops. You can run either P2 or K7. P2 is easier to maintain, as you don’t have to do the MK/PK switch every couple of weeks in order to prevent sedimentation in the black ink lines.

@Walker - I take it that those zips don’t contain the complete set of new curves, do they?

No. They contain our workshop curves for P2 and a set of recent K7 curves.

We run P2 in our workshops because in our workshops we have up to 6 people printing full-tilt on every paper and every printer. Imagine running a workshop and switching PK/MK 30 times a day x5 printers. That’s a lot of wasted time!

Now, if we had dedicated K7 5MK and dedicated K7 5 PK this would take up our entire workshop space. P2 was actually just as self-serving for us as for our customers. Like everything we create, we use it ourselves.

//

Post Piezography redux (and once we can get our old QTR curves off the QTR install) I’m going to start publishing more rounded sets of updated curves for x8 and x9 systems starting with K6&P2 (for their logical usefulness) and then going to K7.

best,

Walker

I understand very well the advantages of using P2 in workshops and so not having to do the MK/PK switch repeatedly. My point was that despite the practical advantages, you wouldn’t be doing it if there was something deficient in the resulting prints, and so people shouldn’t be scared of it in their own printers on account of that statement on the IJM P2 page.

We consider 4 inks a minimum for a good quality print on a modern print-head with QTR (dual quad is very good as well, equal to K6 in my opinion, but even more adaptable). Piezography (public) started as a K4 system using the epson dither and eventually allowing dual-quad with ImagePrint and StudioPrint. I used dual quad for years and years as did Tyler and many others including Mark Savoia to this day. (It was a different dither in SP called smooth diffusion that had the ability to position a dot of ink directly on top of another dot. QTR doesn’t do that.) It worked (works) well. 5 inks does not allow dual-quad + gloss so that is out as an option. Six inks is great. Seven inks is really the best (on all papers) but more limited on x8 heads vis a vis paper and black ink switching. We say this in our workshops as well when explaining why we are running K6 vs K7 for practical reasons.

I think Jon has said this at various points on and off-line.

Nobody should be scared of putting ink in their printers using more shades of gray than 3. It’s (by default) going to make a higher quality print than ABW when calibrated.

Best,

Walker

“Post Piezography redux (and once we can get our old QTR curves off the QTR install) I’m going to start publishing more rounded sets of updated curves for x8 and x9 systems starting with K6&P2 (for their logical usefulness) and then going to K7.”

I’m confused over the use of the term new: it can mean more rounded and updated as you mention above - but it can also mean curves for new paper/ink combinations.

I intend to print pure carbon on matte paper. If I order some custom profiles, should I stick with K7 ? Will they be calculated using the newer methodology ?

Thank you for your patience !

The P2s are the most recently linearized, and linearized also with a new version of our internal (very complex) linearizer that does 256 patches. I updated it to work iteratively. I would test w/ the CAR P2 Hahnemuhle Photo Rag curve and also the K7s and find which one looks the best to you.

cheers!

Walker

In the ZIP file you attached which contains P2 profiles, there are 5 profiles named CAR. In the ZIP file you attached which contains the newer K7 profiles, none of them are named CAR.

“Post Piezography redux (and once we can get our old QTR curves off the QTR install) I’m going to start publishing more rounded sets of updated curves for x8 and x9 systems starting with K6&P2 (for their logical usefulness) and then going to K7.”

The sample print you made for me was done with your recent P2 Carbon profile for Hahnemule Photo Rag. It was very impressive. However, going forward, will the K7 Carbon profiles be even better ? Having just loaded K7 inks I am reluctant to change the position of the inks and lose ink in the process (if that’s what will happen), particularly if K7 Carbon profiles are in the pipeline.

I seem to have arrived on the scene during a time of transition, and it would be helpful if you could save me from having to go in circles, wasting time and money in the process.

Many thanks !

I would start with the P2s. The K7 curves were not profiled on the carbon printer. Generally they all play well together but these P2s are more dimed.

cheers!

Walker

Update: I ordered custom K7 Carbon curves for 2 papers and received them in very quick time. They are outstanding !

When I think of the time and expense I wasted previously, I have to laugh. On a positive note, now I really appreciate the difference.

I’m thoroughly delighted with your support and instructional materials !

I’m thoroughly delighted with your support and instructional materials !