Yes, we understand information has to be presented in many places and ways, and visual demonstration is always best to help people understand a process than written instructions and still photos.

I totally agree that Epson should be more proactive about helping people maintain their printers, but you have to understand, it’s in their best interest for the user to pay for service or buy a new printer every few years, than have users personally maintaining and using the same printer for several years. That’s where we come in- to help you learn techniques to keep your printer in top working condition and lasting a long time, which the manufacturer won’t tell you (and doesn’t want you to know).

I also agree the online community support is wonderful, and is a helpful/efficient way to read other people’s experiences, read/share interesting things people are doing, access information documents we provide, and is one location to ask any questions you may not find an answer for- then the information is available for others to benefit from

PGross’s post on how he got his R3000 working again is detailed and helpful (he successfully got his printer working again). I plan to do more testing (especially in regards to injecting ink or cleaning fluid thru the cartridge end of the line- and how that effects the dampers), then clarify and write instructions for a similar procedure so people can confidently/successfully clean and fix their own printers.

I suspected this is the other cleaning kit you purchased. This kit is essentially the same as ours, but includes a different cleaning solution. Although the product page says it works on the R3000 printer model, if you look at the illustrations and instructions- the cleaning kit is to be used directly on the print head, just like ours. The R3000 is the only model listed that has internal ink lines and dampers- all the other models they list are desktop models that you can easily access the print head for cleaning by removing ink cartridges. With a pro model printer- you need to disconnect the dampers to access the print head for direct cleaning. I suspect it was an oversight on their part to list the R3000 as a supported model with this print head cleaning kit, as they didn’t include information for accessing the print head with this model.

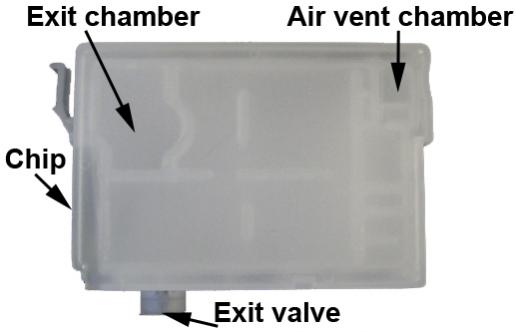

When you receive the cleaning kit, it may be best to start by drawing 1ml of VLM ink into the syringe, connecting the cleaning cart to the VLM cartridge channel, and gently inject 1ml of ink into the line. Don’t apply too much pressure if there’s strong resistance, but with light pressure and a small amount of fluid you may hear a slight spurt from the print head end (the blockage opening up), then reinstall the cartridge, do 1-2 regular cleaning cycles and print a nozzle check to see how things look before taking apart your printer. Have you already clean your printer’s capping station, wiper blade and bottom of the print head by following the instructions I directed you to?

Please keep me posted and let me know if you have further questions, or there’s anything else I can help you with.

Best regards~ Dana