Hi there,

Well, it seems I really need your help there.

A week ago I had my Epson 9900 serviced by a technician in order to change the whole dampers unit, and also the cleaning station unit. So far I had never had missing nozzles in the checks, just misfiring ones from time to time but nothing serious. We printed some three or four nozzle checks right after the service, and all seemed good.

The day after I installed the Piezoflush carts (that I already used in the past when loading the piezo inks) and I made one init fill. I left the machine off for a week, leaving the piezoflush inside of the machine.

Today, I decided to perform a second init fill, in order to completely clean the machine and the head. I do not know whether this will have any implication, but I will mention that ink came out of the maintenance cart because it was too full! I had a bucket below and cleaned the mess right after…

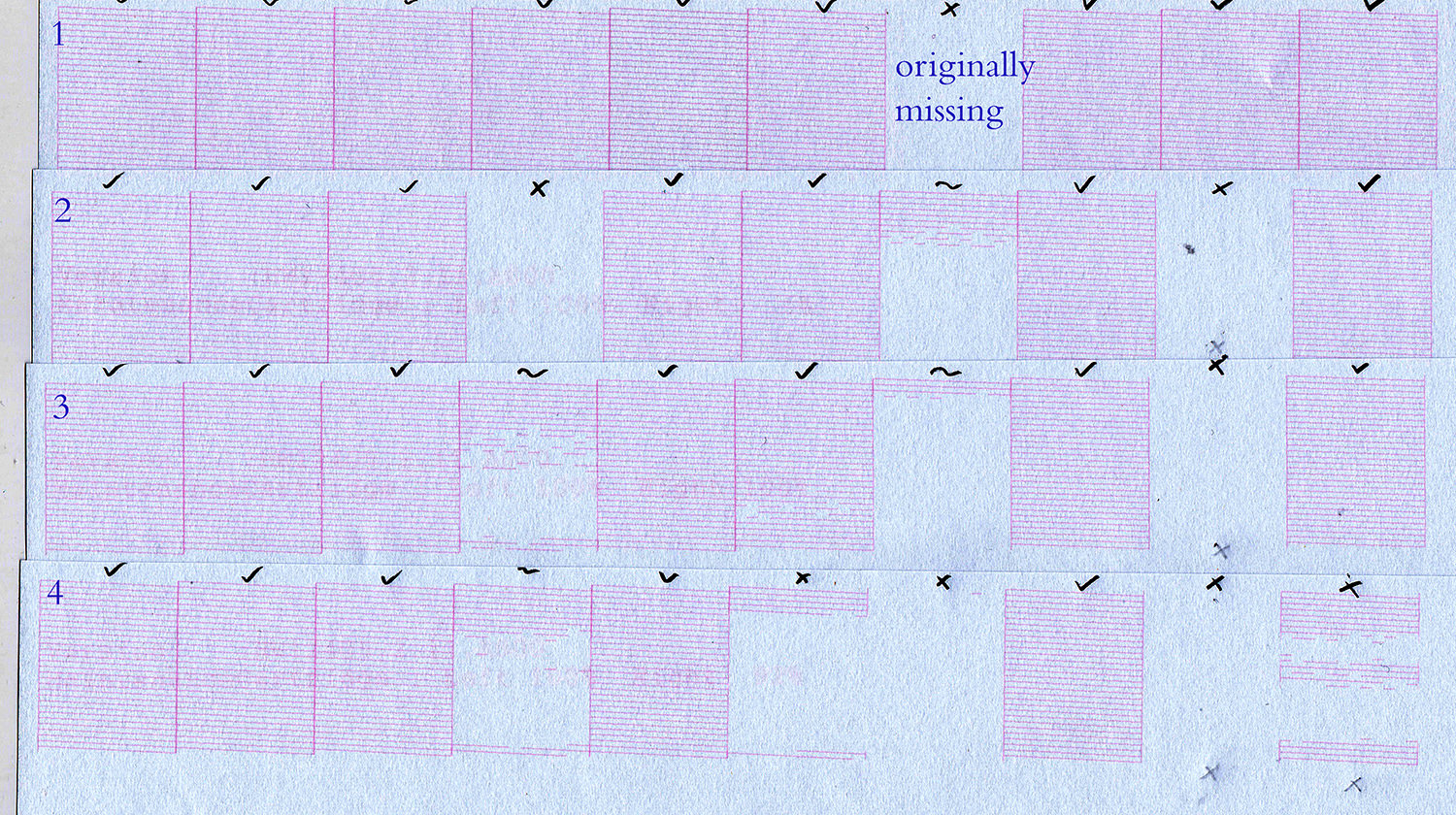

After this second init fill made a week after loading the printer with piezoflush, the first nozzle check showed quite some gaps in the nozzles of several inks. Right after a few more nozzle checks, I saw that all the inks quickly printed perfectly with piezoflush, but with the exception of the 7th position of the nozzle check (LB, right?), which went from printing a few lines to printing none at all.

To my surprise, when I checked the ink lines, I saw there was zero (nada) ink in one of the ink lines!

I checked the cart of LK, and I saw the ink level had gone down MORE than the other carts. In other words, even if there was no ink in the tube, the piezoflush had been leaving the cart! I decided to rule out a problem with the cart, and so I changed the LK cart for a spare new cart with a brand new LK chip (that I fixed myself). I filled it with new piezoflush and I made a second init fill. The ink line did never got any ink into it.

I checked the LK cart and again I saw that the piezoflush level was going down!

At this point I will have to leave the printer for a week off (I am leaving) and I will avoid printing any check or anything at all (not to fry the head on the LK since there is no liquid apparently reaching the head). However, I do not know what to do?

The serviceman changed the pump but if the pump was malfunctioning I suppose TWO inks would be missing in the lines, not one. The other hypothesis is that the LK damper was defective in the new selector unit, and maybe is blocking the piezoflush to pass through? However, this hypothesis would not explain why the piezoflush level is actually going down in the LK cart.

Another hypothesis I tried to rule out is that the missing line does not correspond to the LK (seventh position on the nozzle check) but maybe another cart, if the guy by mistake inserted the ink likes in the wrong sense when connecting them to the head again? I saw on the lines that that tube with no ink was coming from the right (right cart pannel then) and I also see that the line with no ink is the first in the cluster… So I also tried to change the Magenta cart (which is the first in the row of carts to the right door) for a new one. Did the same, init fill, no results.

So, basically, after 3 init fills today, I have been draining the piezoflush and nothing is coming to that tube line. It seems to me quite a coincidence that the problem has appeared right after the service. I also have to mention that these is a whole different set of carts, but I already used them in the past for piezoflush and never had any problem. I also changed 2 out of the 10 for brand new (LK and Magenta, as explaineda above), same results.

When I come back in a week I will also be here for another week, before leaving for a month or so. So I am not only tired, frustrated and depressed, I also fear that if I do not solve this problem quickly when I come back, the printing head might go bananas and then I will have a bigger problem!

To accompany this story, you can download here the files of images showing the problem:

That being said, and to end this post, I suppose my problems with my printer, at a cosmic scale and considering the problems most of the human population out there is having on this planet is quite minute.

But anyway, it would be really very much appreciated if someone can help with this.

At this point, I am seriously considering to embark on manual caligraphy on papyrus rather than inkjet…

Cheers,

Rafael