Mine is KFLE000051. There’s also another number which is not marked as a serial: CA1640000HR8523284. FWIW. I think what you really want in order to test my idea is the serial number of the print head, if such a thing exists.

I’m going to reply to this post of Jon’s here reporting Kelly’s test results so far, rather than continue to hijack JMiller’s thread. I assume that those tests were with JMiller’s carts, but I can’t be sure. Eventually you’ll have my carts and it will be interesting to see if you get the same.

The subtext of Jon’s post is that testing indicated that the problem appears to be printer cleaning. If I were to try again, which I’m not about to for the moment, here is what I could send you as proof of cleaning:

[ul]

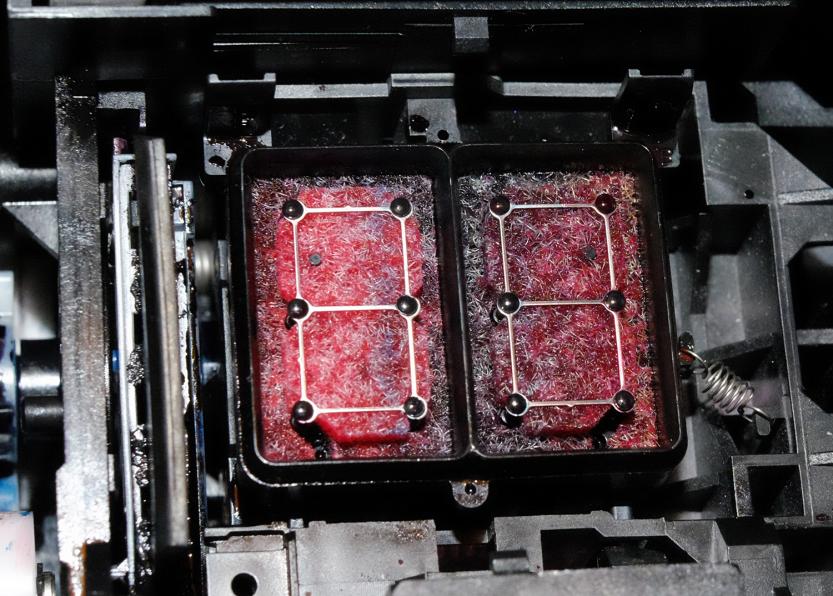

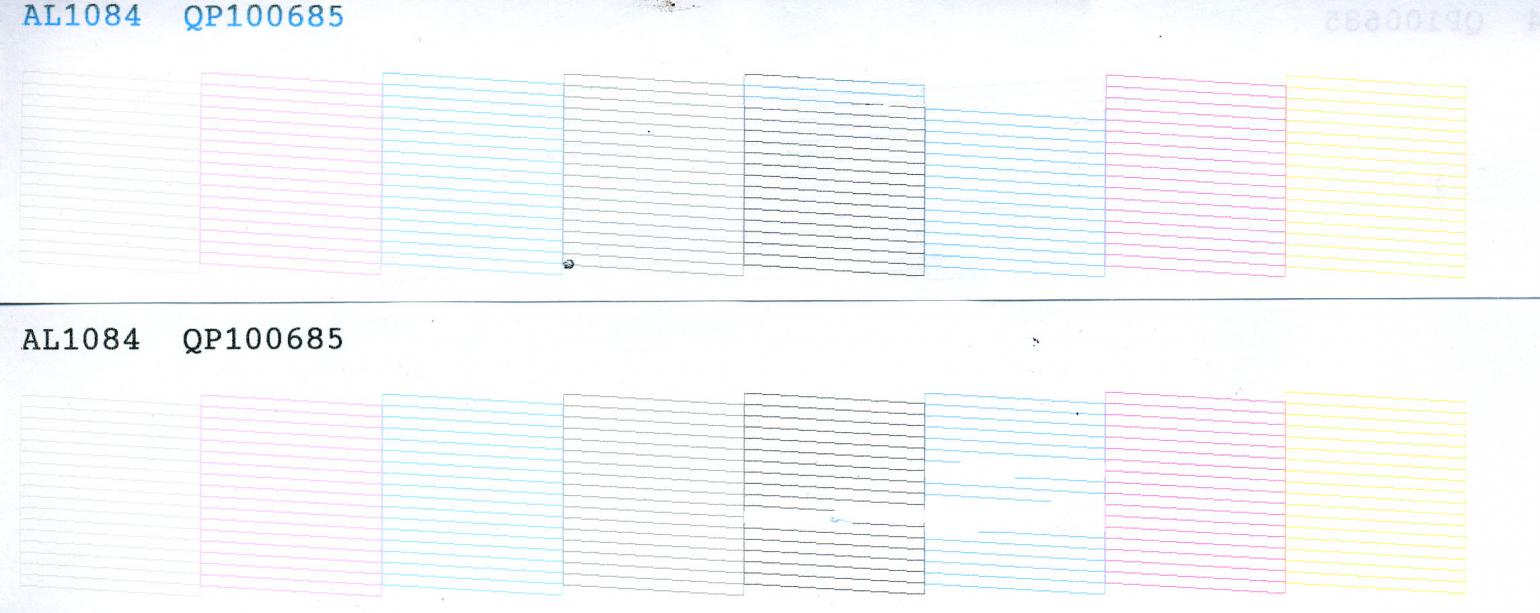

[li] I could use a macro lens to photo the capping station after cleaning. I use several rounds of flush to dissolve any ink and then distilled water to help syphon it off. Gentle paper towel after each application of fluid. At the end the capping station is pretty much white. Is that clean enough? [/li][li] I could also shoot the wiper blade. This is a bit harder to see, but eventually nothing much comes off the top or sides onto the q-tip. I run my gloved finger along the blade and it feels smooth and nothing comes off onto the glove. Ditto. [/li][li] I could shoot the cartridge bay to show that there’s no dried ink around the nozzles, although that’s hard to shoot clearly as well I’d imagine. [/li][li] It’s harder to show a clean print head, but what I could do is shoot the series of paper towel strips. The first would show some gunk, since there’s been some leaking. The second would show less. But the third or fourth there’s nothing, other than a few small spots where the towel is pulling a bit of ink from the head. [/li][li] I could also do a scan of the nozzle check before taking out the flush carts to show that there’s no clogs. [/li][/ul]

I’m starting to lose count of the number of times I’ve done this, perhaps 4-6? I do it before each fresh attempt, since it’s the only way to maximise the chances of success if there’s been leaks.

Perhaps Jon is right - I may have bought someone else’s problems, or at least a printer that refuses to work with refillables. We’ll find out when I get the instructions, send the carts, and you test.