The history is that after agonising (here) about whether to buy a new R3000, I bought a second-hand R2880. In another thread I had trouble getting it working, but this seemed to be caused by me not following the filling instructions to the letter.

I am printing on a R2880 using ConeColorPro inks.

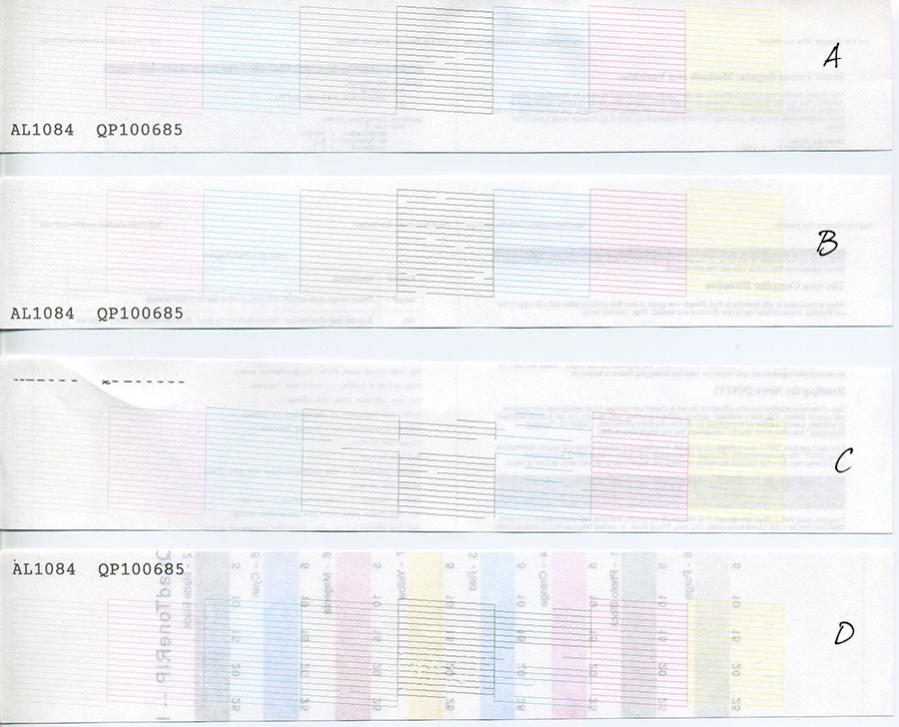

My problem now is that having achieved a good nozzle check, I can’t keep it for long. Attached is a scan of a series of nozzle checks.

- I start with a perfect nozzle check.

- After a short period of time (24-48 hours) I lose one or two nozzles on PK, as per A. Not a really big deal, as only one missing nozzle won’t show in a print and it’s easy to fix by printing a calibration pattern or a block of PK using a custom curve in QTR.

- After another day I get more gaps on PK, as per B. I wouldn’t print like this, and so more purge printing to clear it.

- After several more days I get a nozzle check like C, where the gaps have grown and spread. What to do now? Sometimes a set of purge prints will clear it. Other times a head clean is required.

- The head clean is not without risk, as on at least one occasion I lost a channel (LK I think) that had been printing just fine. This is harder to deal with. I put a flush cart in this channel, do a head clean, print purge patterns, switch back, another head clean and purge patterns, and it’s ok again.

- So I get a good purge pattern again, and start the cycle over. The cycle 1-5 repeats itself.

- Now I get to the stage where I start to get bleeds between channels. As per D. (Sorry that this is printed on the back of something else - PK is bleeding into C.) This is not the worst example - M also bleeds into yellow.

- Anxious to avoid head cleans, I clear things like this using purge patterns and custom QTR curves where possible.

- Last night I had a good nozzle check and made some prints, but tonight PK was nearly completely gone. I printed a block of black using a QTR custom curve, and had ink drips on the page.

- In frustration I have put flush carts in for the moment.

Now I’ve been reading these forums long enough to know what the standard answers are:

(i) Follow the filling instructions to the letter. Check. It took me a while to do this correctly, but eventually I did. See the other thread. The fact that the carts are not draining, and that I can get a clean nozzle check doesn’t suggest filling issues to me.

(ii) Maintain humidity. Check. If you look at my delivery address you’ll see that I live somewhere that is supposed to be dry. But in fact where I live it’s ok and especially at the moment. Moreover I have tried keeping the printer in a plastic bag and with a small container of water in the printer with a sponge in the water. ( I know you don’t recommend this, but I’m getting desperate). I’ve tried leaving the printer on and leaving it turned it off, both with and without the water - nothing much helps.

(iii) Follow the cleaning video. Check. I did this several times as described in the another thread. I did it once just before I successfully got the printer working the first time, so the current state of the printer should have commenced in a clean state.

I’m just about at my wits end. I know from experience that even with OEM carts these printers can clog all too quickly, but this is silly.

What do you suggest I try next? My only idea is to repeat the cleaning routine. Perhaps I missed a spot. And in any case, with bleeds between channels and now ink dropping, it’s likely to need a clean now, even if that wasn’t the cause.

I hope that you have some ideas.

Silly non-universal power supplies.

Silly non-universal power supplies.