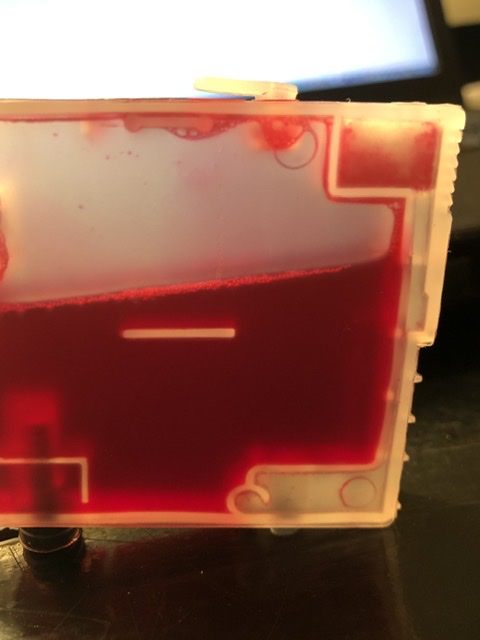

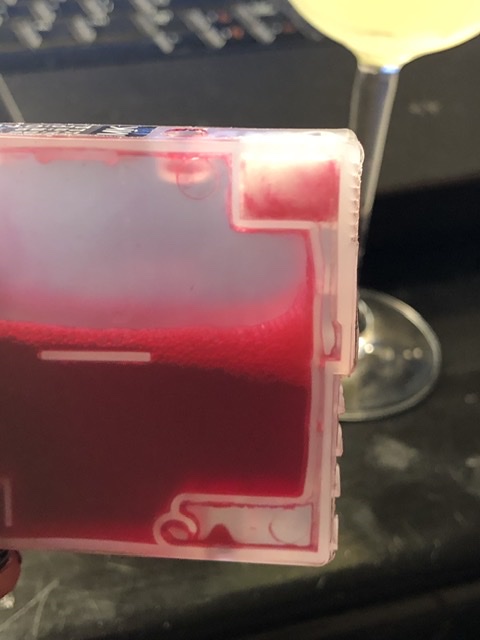

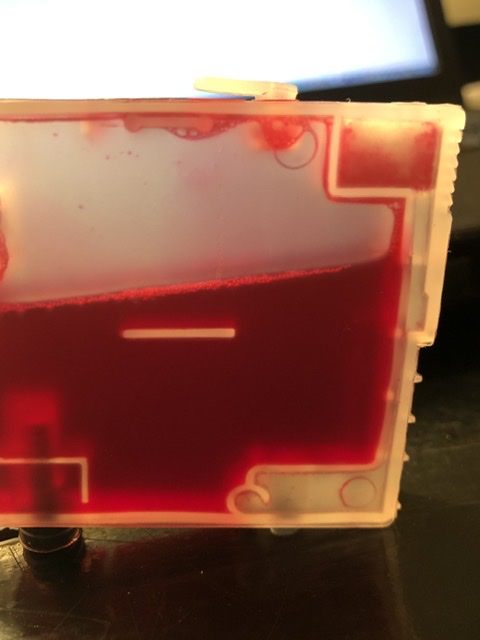

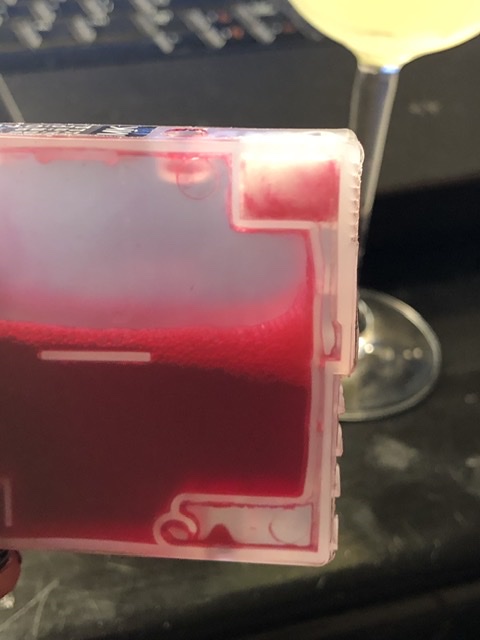

I am incapable of preventing the foam in the vents from filling with ink.

Today I just installed a new set of cartridges with piezoflush and was EXTRA careful - but after one use there’s already some piezoflush in the foam.

I followed the instructions PRECISELY and even waited to remove the tape after installing the cartridges. And then I tape the vents with soft electrical tape anytime I have to remove or reinstall a cartridge, or while filling it, to prevent a change of pressure in the main tank from pushing ink into the vent well. But there’s always a little bit of ink that enters into the vent cavity that eventually makes its way up to the foam pad through capilarization.

Is there anyway to prevent this from happening?

PF is a little different than our regular ink. It has incredibly powerful surfactants that penetrate heads (and carts, etc) but it won’t dry out so air will continue to go through the vent without issue.

-Walker

1 Like

I won’t worry about my flush carts then.

This also happens to the ink cartridges and wondered if you knew how to prevent it.

I seal the vent hole with electrical tape anytime I need to manipulate a cartridge and that seems to help - but not entirely.

I have also had success blowing through the vent hole with the cartridge at an angle to push the ink back into the main chamber (Fill hole open and covered with some paper towel). This works well too but it always seems to creep back through eventually.

How big a deal is it getting ink in the foam?

I haven’t had any ink flow issues with the latest carts like I did originally so maybe the cart design has been improved. The chip design is definately better and I haven’t had a single invalid cart error with the new carts. The rubber gasket on the ink outlet also looks different and seems to seal better around the cones.