Hi,

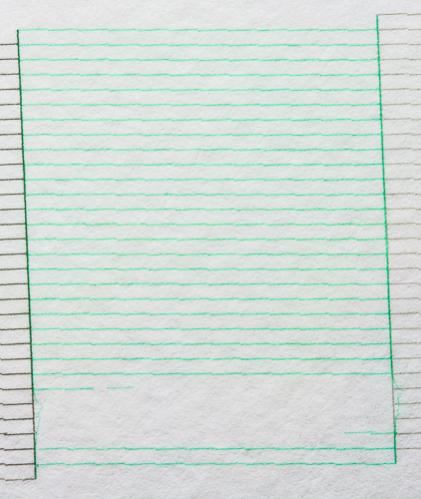

I’m looking for your thoughts and experienced advice on my next steps in dealing with about 4 lines of missing/deflected Green nozzles. Here’s the nozzle check pattern:

(Edit: See the pattern in the following post on this thread; my first attempt to include the jpg here didn’t work)

Note the odd deflection on the left and right of the missing nozzle area.

Some history and key data points:

[ul]

[li] my 7900 is 5 1/2 years old[/li][li] this is the first time ever that I have not been able to easily clear a missing nozzle using CL1 cleaning[/li][li] from January to June this year I had ZERO clogs, not unusual for me in the winter months; I typically have more missing nozzle problems in the summer[/li][li] the printer is maintained at 45-60% humidity, 68-78 degrees F[/li][li] I shake my cartridges every 4-6 weeks; wiper is changed at least yearly and cleaned periodically[/li][li] I print at least once or twice a week[/li][li] flushing box has never appeared to need cleaning[/li][li] I occasionally clean the cap station pads, though they have never looked like they needed it[/li][li] the Ink Selector (containing the five dampers) has never been changed[/li][li] the printer has never required a service visit[/li][/ul]

What I’ve already tried:

[ul]

[li] Initially I was missing only a few nozzles in green; after a few CL1 cleans with still missing nozzles, I had to put in a new cartridge to continue cleaning attempts since I was already down to 1%; the removed 350ml cartridge was dated 2009 (yes I know, that is a long time)[/li][li] After a few more cleanings (CL2, CL3) and also printing a purge block of 100% density green, the missing nozzle area got bigger (see image); the missing nozzles area now does not change with any further cleanings[/li][li] Heaviest clean I’ve done is a single CL4 on the O/G pair; I have not done any Power Cleans or SSCL[/li][li] Head soak using Bounty towel with warm distilled water[/li][li] saturating cap pad for O/G with CLF007 cleaning fluid (from AmericanInket) and parking head overnight[/li][/ul]

I really like this printer. It has worked extremely well for me since I’ve had it, and I don’t relish having to change horses. But I need to be realistic and consider my options carefully, especially concerning cost. I should also mention that I’ve done a lot of “technician work” on equipment similar to these printers and feel comfortable doing any repair work myself. I have the service manual and field repair guide and the necessary tools.

Here are the options I’m considering:

[ul]

[li] Purchase a refillable cartridge for O/G and PiezoFlush, and do INIT.Fill sequences to flush the O/G channel (with 48 Hour rest in between)[/li][li] same as above but PiezoFlush in all channels to possibly prevent problems in other channels from developing[/li][li] Purchase a new Ink Selector and replace[/li][li] Purchase a new Ink Selector and Head and replace[/li][li] Purchase a new 7900 (with extended warranty of course)[/li][li] Purchase a new Canon instead[/li][li] Convert the 7900 to Piezography K7 (which I’ve been wanting to investigate anyway, but the downside is that I do need to print color as well)[/li][/ul]

Based on your experience, the history of my printer, and the nozzle pattern above (which to me indicates a problem in the head itself):

Should I try an SSCL?

Is it worth trying the PiezoFlush, or should I just bite the bullet and replace the InkSelector and head?

Is there any sense in first trying a new Ink Selector without replacing the head?

I read here on the tech forum about a possible “nuclear cleaning” option for a removed head that Dana was investigating. Has this been documented and if so should I try it?

Are there any other options which I should consider?

Thanks in advance,

Dave