On my 1430 used solely for creating Digital Negatives, I very recently obtained nozzle checks with the LM (ink #5) channel showing darker horizontal lines (specifically the third and fourth horizontal lines from the top) more typical of the surrounding channels, either LC (#3) or M (#4). (I have fairly regularly gone through all of the recommended cleaning procedures as well as forcing through piezo flush.) Is it possible that the surrounding LC and M channels are bleeding into the LM channel? What might be causing this, and how can the problem be solved?

Can you post a picture of this? That would help,

thanks

Walker

Walter, I couldn’t get into the site. I guess I need to have my password reset again.

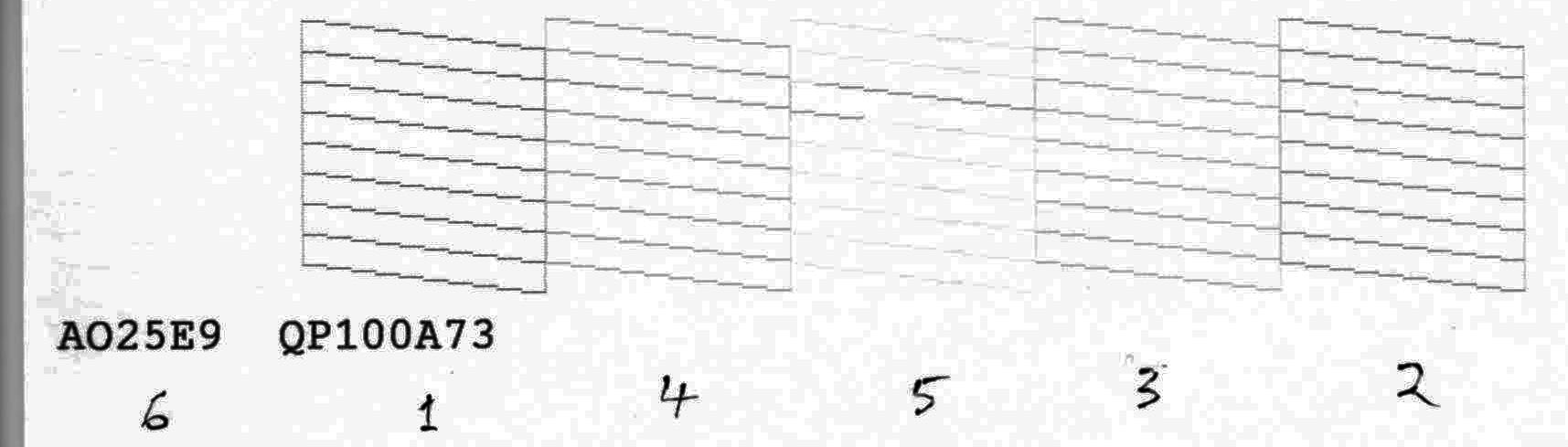

Anyway, I’ve attached a scan of the nozzle check after decreasing brightness so that the weak lines can be seen. As you can see from the fourth nozzle from the left, the ink is fairly light (#5) with some darker third and fourth horizontal lines .

Thanks,

Alan

Hello

This happens fairly often on both my Epson 1400 and 1430 especially after a head cleaning whether printer initiated or initiated by me. Also this may be due to ink build up on the split pad on the left side of the printer. LM and LC seem to be the two most affected ink positions. To clear this I resize the appropriate QTR flush image to 720 dpi, duplicate it and print in calibration mode at 25 or 50 percent on 8.5 x 11 photo paper.

JP

JP (Mazer),

Thanks for the response. I realize I’m admitting my ignorance here, but there are a few things I didn’t understand.

(1) Does the word “resize” mean the QTR term “scale”?

(2) When you refer to the “appropriate QTR flush image” (aQfi), I don’t know what the “flush image” is in QTR. And, how does one “duplicate” it?? Is it merely using the calibration image with piezo flush?

Thanks,

Alan

In the Piezography Community Eidition software in the Images directory there are QTR flush images. In the case where LM appears to be overprinting with a darker tone in the nozzle check, I would load that particular flush file in the QTR print application, resize it so that it fits on a 8.5 x 11 sheet of paper and print it via the QTR print application on plain or photo paper in The QuadTone Rip Calibrarion mode with a Calibration Ink Limit of 25 percent.

Resizing can be done in the QuadTone Rip application using the Position and Scaling controls to fit the flush image onto 8.5 x 11 paper. I notice that the flush images are of a different size in the Piezography Community Edition software than what I originally downloaded in the past.

There is no need for piezo flush.

Hope this helps, John

The basic idea is to print using, in this case, just the LM ink which the QTR flush file allows you to do in QuadTone Rip calibration mode. It’s also possible to clear this problem by printing an image with lighter tones, but it may take a little longer.

John

Thanks John, It looks as if I have some learning and work to do. Alan

I’m surprised that there isn’t an IJM response to this issue, but I assume there will be. I’ve had this exact problem on several desktop printers - both colour and Piezo. You can certainly print it out as suggested using flush images and calibration mode in QTR, but I predict that it will come back.

The IJM position is usually that this is caused by a dirty capping station or wiper blade or print head, and you need to do a clean. That’s certainly possible. If the problem still persists, then they say that it could be a faulty capping station and pump.

However on my Piezo R1900, I had this once, and given my precise symptoms I suspected two carts as being slow leakers. I replaced them and the problem went away, which I consider proved the point.

When you get this sort of cross-channel contamination a clean is a good idea. But it can be hard to know what the precise cause is, if the problem doesn’t go away after a cleaning routine. My view is that cartridge issues are more common that people realise, and IMHO it’s not a coincidence that IJM have just launched a completely new desktop cart design.

On my Epson 1400 and 1430 when this problem occurs it is always after a head cleaning whether initiated by the printer, manually by me or after a cart refill. I agree the carts could be the cause of the problem as my printers are well maintained, but so far I haven’t been able to say definitely. Once the problem is cleared by printing flush images, it stays clear until the next head cleaning when it may or may not show up again.

John

I had similar symptoms once with an older printer (R2100) and a non-IJM CIS. After a head clean I would always get random and moving nozzle gaps that were remarkably hard to clear, but once they did, they were fine until the next head clean. I got rid of the CIS and that particular problem went away, and I’ve always assumed that there was a printer / CIS incompatibility. It’s not clear to me that cross-channel contamination after a head clean is necessarily the carts, as my experiences with it were independent of head cleans. It could be the capping station.