Hi, I just got around to installing the piezography inks (special edition) in my 3880 (had to use up the remaining color first). Everything seems to have go as expected with the install. I had yellow staining, but printed a few full sheets using the QTR calibration mode and the color for pure ink 4 and that seems to have cleared.

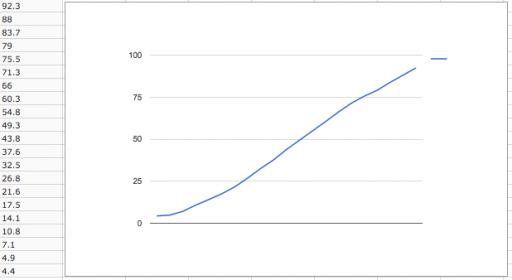

The few test prints I’ve made seem to have very dark shadows, and printing a 21step target produces a non linear output in from about 40% to 100%. Before I fixed the yellow stain it was also non linear throughout the whole range. The inks don’t look like they have residual staining left, but just in case I did an additional power clean and the results look the same.

I’m printing on Epson Luster for the testing.

I use the QTR Print Tool as described in the manual.

The 21 step target is from QTR, 21step.psd.

I verified the ink order using the QTR ink pattern page. Checked with a densitometer and they seem to match the correct order in the paper curves.

Nozzle checks are correct.

Curve data read with a color monkey and using the L values.

I’m out of ideas. Is there something I’m missing?

Data:

92.30

88.00

83.70

79.00

75.50

71.30

66.00

60.30

54.80

49.30

43.80

37.60

32.50

26.80

21.60

17.50

14.10

10.80

7.10

4.90

4.40

Please let us know what curve you are using. It is indeed out of lin . . . This may be a generationally old curve however. I’m in the process of going through our entire back-log of curves and validating them . . . .

-Walker

Also, what GO curve are you using?

best,

W

I’m using the 3800-3880-MPS-EPluster.quad curve installed with QTR. It’s dated Nov 5th, 2010. I’m using the 300000 GO curve in the same directory. I also tried the 3800-3880-MPS-EPexFiber.quad curve with the same results (then switched testing over the the Luster paper).

I know this might sound weird and not normal InkjetMall behavior, however I’ve spent 12 years not being part of IJM and this was something I did to “just-get-prints-done-damnit.”

I can’t find a K7 curve that is compatible at the moment. I need to validate tomorrow . . . and/or linearize a new curve for this new generation of inks/papers/etc . SO!

Try printing with this profile (attached link below) from Print-Tool (you can download the trial if you don’t have it) using Perceptual mode and let me know what you think of the prints/measurements. You can use the profile with the same 3800-3880-MPS-EPluster.quad curve.

Place this icc in /Library/ColorSync/Profiles/

It will be at the bottom of your ICC list in Print-Tool and be called QTR-LGebhardt2.icc

Profile:

http://inkjetmall.com/tech/LGebhardt2.icc.zip

Let me know.

best,

Walker

No risk of that statement being contradicted. The phrase “crushed shadows” is ringing in my ears.

I wonder how that curve would look after being processed by the relinearisation droplet.

How old is the printer? If it’s had a fair bit of use, then it may have drifted, but a relatively young 3880 shouldn’t exhibit that degree of non-linearity.

Lin droplet:

Print with Gamma 2.2 (or however you printed before sans ICC)

http://inkjetmall.com/tech/3800-MPS-EPluster-2010-lin.quad.zip

I had to wrangle some CGATs madness to get that freaking lin to go.

Validating all this now FYI.

best,

Walker

[QUOTE=walkerblackwell;10729]I know this might sound weird and not normal InkjetMall behavior, however I’ve spent 12 years not being part of IJM and this was something I did to “just-get-prints-done-damnit.”

I can’t find a K7 curve that is compatible at the moment. I need to validate tomorrow . . . and/or linearize a new curve for this new generation of inks/papers/etc . SO!

Try printing with this profile (attached link below) from Print-Tool (you can download the trial if you don’t have it) using Perceptual mode and let me know what you think of the prints/measurements. You can use the profile with the same 3800-3880-MPS-EPluster.quad curve.

Place this icc in /Library/ColorSync/Profiles/

It will be at the bottom of your ICC list in Print-Tool and be called QTR-LGebhardt2.icc

Profile:

http://inkjetmall.com/tech/LGebhardt2.icc.zip

Let me know.

best,

Walker

[/QUOTE]

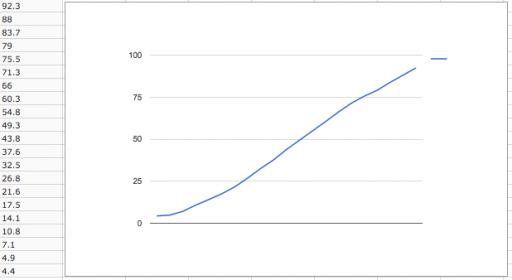

Well the profile fix worked very well. It could use a few tweaks to be fully linear, but it’s 95% of the way there. Here’s the data:

92.00

87.10

84.10

79.90

75.30

70.60

66.30

62.40

57.70

53.70

49.50

44.50

40.80

35.40

30.20

25.70

21.60

16.30

11.10

8.20

3.30

I made one print and it’s very nice. What’s the step to make a correction profile like this? It could be quite handy to tweak a curve.

[QUOTE=walkerblackwell;10731]Lin droplet:

Print with Gamma 2.2 (or however you printed before sans ICC)

http://inkjetmall.com/tech/3800-MPS-EPluster-2010-lin.quad.zip

I had to wrangle some CGATs madness to get that freaking lin to go.

Validating all this now FYI.

best,

Walker[/QUOTE]

I tried this curve as well, and it seems even more linear:

93.10

88.70

84.00

78.90

75.60

71.90

67.60

63.20

58.70

54.00

50.20

45.50

41.30

36.50

31.70

27.10

22.70

17.60

12.70

8.20

4.50

So how was this new curve made? Was it based off my readings, or did you rerun the curves on your printer? I’d love to get updated versions of many of the other papers. I haven’t tried any of the matte papers yet, though I just noticed they ones shipped with the latest QTR in the 3000-3880-K7 folder seem to be named for the 2880. Is that a mistake?

[QUOTE=Brian_S;10730]No risk of that statement being contradicted. The phrase “crushed shadows” is ringing in my ears.

I wonder how that curve would look after being processed by the relinearisation droplet.

How old is the printer? If it’s had a fair bit of use, then it may have drifted, but a relatively young 3880 shouldn’t exhibit that degree of non-linearity.[/QUOTE]

My printer is about 5 years old, but it’s had relatively light use. I think under a thousand prints, and many of them were small. I think in all that time I only went through 2.5 sets of the primary colors and about twice that for the light versions.

What is the relinearisation droplet?

See this blog post on using the relinearisation droplet.

I believe that this is how Walker created the 3800-MPS-EPluster-2010-lin.quad file in post #8, and the linearisation checker results that you posted in #10 are consistent typical relinearisation droplet results.

Can I just clarify? The numbers in post #9 were achieved by converting the 21x4 to LGebhardt2.icc, printing and measuring - is that correct? If so, then like you, I’m a little intrigued about how that ICC was created. This is not a typical shadow-crushing ICC as produced by QTR-Create-ICC.

When the L values are low 3 to 6 Create-ICC doesn’t have any shadows to crush, they are already down there so the “perceptual contrast” is correct already.

This is my understanding of create-icc anyway.

There was a bug in the Quad-Lin droplet that I had to overcome to get it to work with a normal cgats but I did build these with the QTR tools only. Will be posting a solid workflow soon with some interesting workflows and swatches *(built in Generic Gray Gamma 2.2 for Piezography consistency) but I’m still validating.

I want the whole community to be able to calibrate and keep things working perfectly.

regards,

Walker

Just FYI I think whatever device was used to measure the lin and ICC results was not calibrated correctly or is exhibiting shift of more that 1.5L from measurement to measurement. It should be less than .3L if it’s a good device.

best,

Walker

[QUOTE=Brian_S;10744]See this blog post on using the relinearisation droplet.

I believe that this is how Walker created the 3800-MPS-EPluster-2010-lin.quad file in post #8, and the linearisation checker results that you posted in #10 are consistent typical relinearisation droplet results.

[/QUOTE]

Thanks, that’s very interesting. It certainly seems to have worked well in this case.

[QUOTE=Brian_S;10744]

Can I just clarify? The numbers in post #9 were achieved by converting the 21x4 to LGebhardt2.icc, printing and measuring - is that correct? If so, then like you, I’m a little intrigued about how that ICC was created. This is not a typical shadow-crushing ICC as produced by QTR-Create-ICC.[/QUOTE]

Yes, the numbers in #9 came from printing with the “stock” curve and the icc profile. I didn’t directly convert to the profile, but rather used the “Application Managed” setting in the Print Tool and set this profile, along with perceptual intent. However I believe the results would be the same either way.

[QUOTE=walkerblackwell;10745]When the L values are low 3 to 6 Create-ICC doesn’t have any shadows to crush, they are already down there so the “perceptual contrast” is correct already.

This is my understanding of create-icc anyway.

There was a bug in the Quad-Lin droplet that I had to overcome to get it to work with a normal cgats but I did build these with the QTR tools only. Will be posting a solid workflow soon with some interesting workflows and swatches *(built in Generic Gray Gamma 2.2 for Piezography consistency) but I’m still validating.

I want the whole community to be able to calibrate and keep things working perfectly.

regards,

Walker[/QUOTE]

Thanks. I’m looking forward to seeing that.

[QUOTE=walkerblackwell;10746]Just FYI I think whatever device was used to measure the lin and ICC results was not calibrated correctly or is exhibiting shift of more that 1.5L from measurement to measurement. It should be less than .3L if it’s a good device.

best,

Walker[/QUOTE]

I’m using a Color Munki. Reading multiple readings without moving the device it’s very consistent, only varying by .1L at the most in shadow (90%) readings. Moving it and reading the same patch gets the same results. Now having said that I can’t vouch for it’s overall accuracy. The device is a bit old, and the position sensor has gotten very finicky. But once I get it registering the correct position after calibration it produces good results with color.

Then these tools are being used in a novel and non-standard way, judging from the linearisation checker results. Are the ICCs being produced this way, such as the one in post #6, only for printing, or can they also be used for soft-proofing? If my understanding is correct then I’d imagine that you’d use them for soft-proofing “normally”, rather than with the preserve numbers option enabled in PS.

They can also be used for soft-proofing. They were not created in any novel way at all.

Generally what I’ve done in my personal lab that I’ve run (Black Point Editions, then at UVM, then Latitude in Chicago, then Light Work) is a create-icc profile that I’ve printed with in perceptual mode for gloss prints. For gloss prints with luminances under 10 I’ve seen really zero crushing of the shadows.

For matte printing I’ve always used StudioPrint. At Light Work I got matte printing working with my own .quad profiler that I built from scratch but also working in partnership with the icc.

////

So in conclusion, no the ICC above is just a standard Create-ICC profile and the lin’d quad is just from the linearization droplet.

The ICC can be used for both proofing and printing.

best,

Walker

An update. I took the Epson Exhibition Fiber curve that was blocked up on the Canson paper and ran it through the linearization droplet twice. It was decent with one pass and almost perfect after two. The prints are almost a perfect match to the screen when soft proofed (using the profiles at http://www.piezography.com/PiezoPress/blog/calibration/piezography-soft-proofing/).

Thanks again for your help.