We are getting micro banding in the blacks of both are 9800 and 9880. 9800 was fine till we did a head cleaning. How do we fix this, we have done multiple head cleaning already?

Ok, there is going to be a big list of questions I will need answered to correctly diagnose this problem, please answer the following:

1.How long does the printer sit unused with Pigment inks in?

2.Have the cartridges been shaken to disperse the pigments regularly (once a week)?

3.Has the Capping Station, Wiper Blade and bottom of the Print Head been cleaned in the last 6 months?

4.When were the dampers last replaced?

Please answer all of the above questions and I will have a better idea what’s going on.

I moved this thread to the Printer Maintenance Pro 17" -9800/9880

Thanks,

Kelly

Dear Kelly,

- Its school setting so it goes for weeks to days with out being used but as of late it’s being used pretty regularly.

- No the cartridges have not been shaken.

- It was clean two months ago.

- Don’t think the dampers have ever been change.

It sounds like you are dealing with old, gummed up dampers and I would recommend replacing the dampers on these 2 machines if that hasn’t been done within the past year. We recommend replacement of the dampers at a minimum once a year, along with a thorough cleaning of the Capping Station, Wiper blade and bottom of the print head. It may also be wise to replace the ink that is causing the clogging if it’s been sitting, unagitated for an extended period of time, the pigments could have settled out in the cartridge and the printer has sucked up that settled pigment and lodged it into the damper, to prevent any more “gumming”/clogging it would be wise to replace the K ink. We sell the dampers on our web-site http://shopping.netsuite.com/s.nl/c.362672/it.A/id.7901/.f

The replacement of the dampers is a bit time consuming and will require someone with some technical ability to tackle the task. Another option would be to hire an Epson Tech if there isn’t someone available to work on the printers there at school. These printers are getting up there in age, just like with a car, they start needing extra repairs and it starts becoming critical to maintain them to the highest standards and not cut any corners. If the replacement of the dampers and the ink doesn’t take care of the missing nozzles, then you would be looking at replacing the Capping Station and Wiper blade.

Kindly,

Kelly

Hi Kelly,

Our nozzles are not clogged so I’m not sure that it is the dampers. The micro banding is happening with a fully unclogged head. We have run numerous head alignments but they have not helped. I think the nozzles are either firing poorly, ie not straight, or there is a belt problem. Bi directional has looked a little better but still has the banding problem. We have been doing manual paper towel cleanings and it is slightly better. Any thoughts on the best maintenance route to take?

Thanks!

The only time I have experienced micro banding was when there was misfiring nozzles, which will show up on a nozzle check under very close inspection. Misfiring nozzles can be caused by low humidity, do you have a hydrometer to verify the humidity level in the studio? can you post a pic of your nozzle check?

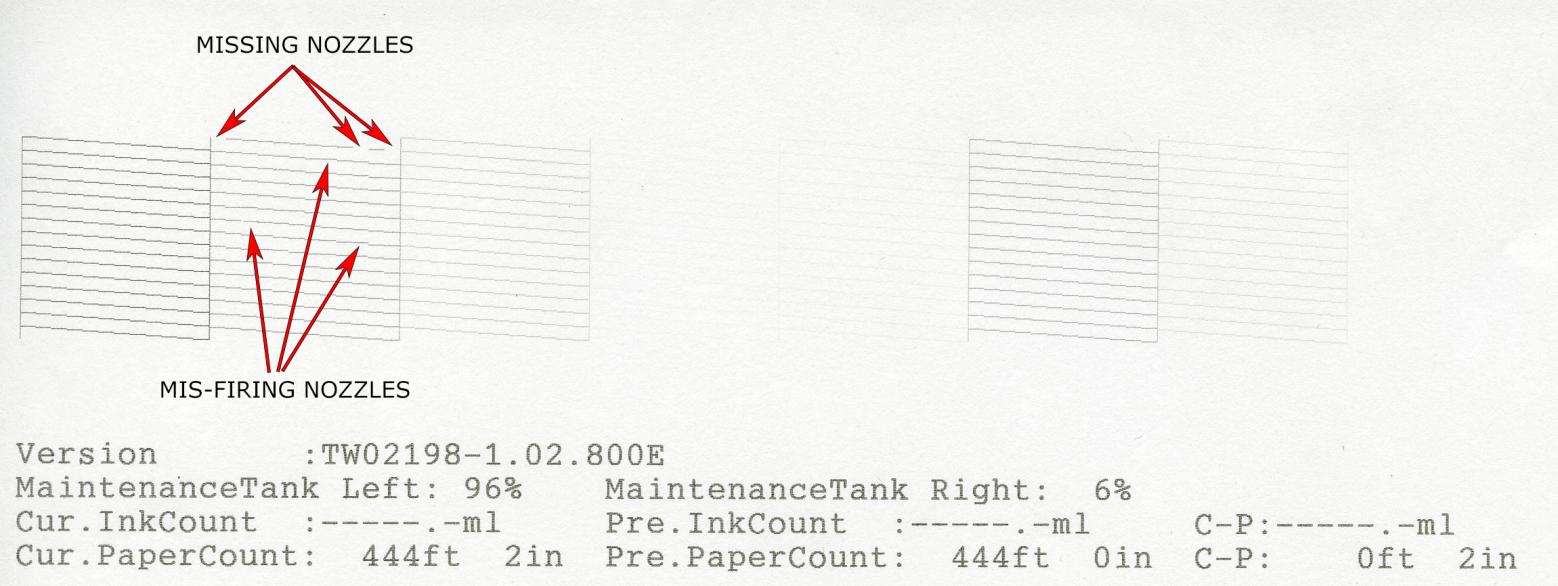

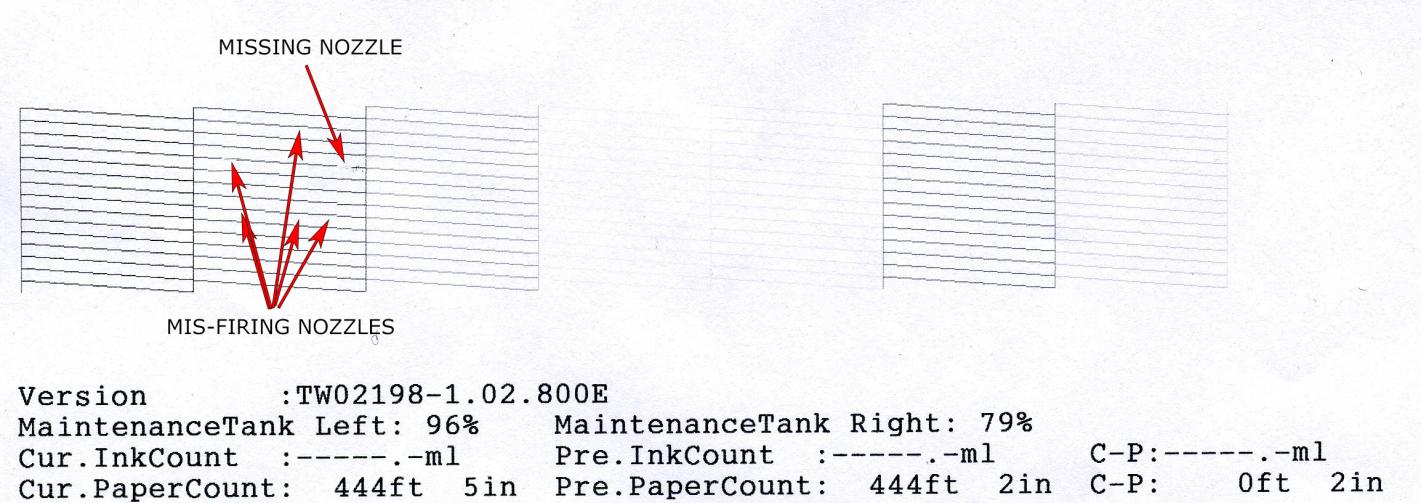

Here are two nozzle checks from the same machine. Image 1. Image 2. This is the image we are testing with.

Hi Nathan~

I am just back to the office after being out with a sick baby for the past few days, and just had a chance to review your thread and nozzle checks.

Your nozzle checks both show missing and mis-firing nozzles in the cyan/shade #2 channels, the black channels both look fine. I have attached your two nozzle checks below, which I have labeled to show the issues I’m referring to. With Piezography, shade 2 prints in the dark shadows, so missing or mis-firing nozzles in the cyan/shade #2 channel can cause banding issues in the dark shadows.

I also think your ink output is likely incorrect density, which happens when carts are not agitated and the printer isn’t used regularly. As per our instructions, carts should be regularly agitated every 1-2 weeks, and printers should be used at least once a week to keep pigments in suspension, and avoid settled pigment, which can cause clogging/flow issues, as well as incorrect output density.

Due to infrequent use of the printers, not shaking ink carts, and not cleaning/maintaining the printers, I recommend you shake all the ink carts to get pigment in suspension, and top off any that are less than 1/2 full (always shake ink bottles before refilling carts), then do one Initial Fill Cycle thru the printer’s control panel to flush settled ink from the lines, and get good/correct density ink from the shaken/refilled carts to the print head. After shaking carts and doing the initial fill cycle, follow our instructions to manually clean the printer’s capping station, wiper blade, flushing box and bottom of the print head. Instructions on how to do an Initial Fill Cycle can be found here: http://www.inkjetmall.com/tech/content.php?151-Initial-Fill-Procedures-for-Epson-Pro-Model-Printers, and instructions for manually cleaning your printer’s internal parts, as well as general maintenance information can be found here: http://www.inkjetmall.com/tech/content.php?133-Printer-Cleaning-and-Preventative-Maintenance

When I came to set up your printers with Piezography a few years ago, I remember you had several printers, including 7800/9800, 7880/9880 and 4800/4880. If you don’t have enough demand to keep all the printers set up with Piezography ink, and the printers are not being used on a regular basis, I recommend installing the set of PiezoFlush carts you already have, and do an Initial Fill cycle to purge ink and fill the internal ink systems with flush for safe storage. This way, you can focus printing and and keep maintenance to one machine, which the others sit safely with flush fluid until you’re ready to use them. It is very bad to let a printer sit unused with pigment inks installed, as all pigment inks will settle (which cause density shift, as well as much faster than normal build up of pigment particles in the dampers), and pigment inks dry solid, which can lead to stubborn or unrepairable clogs in the print head micro-channels. In addition to regular manual cleaning, several parts in the printers should be replaced every few years for regular maintenance, to keep the printer clean and working well (and lasting as long as possible). Dampers are in-line ink filters that protect the print head from particles that could cause clogging, and the set (8) of dampers should be replaced every 1-3 years. Along with dampers, the wiper blade, capping station and flushing box should also be replaced about every 3 years (as well as being cleaned on a regular basis).

I hope this helps. Please let me know if you have questions, your results after doing what I suggest, or there’s anything else I can help you with.

Best regards~ Dana