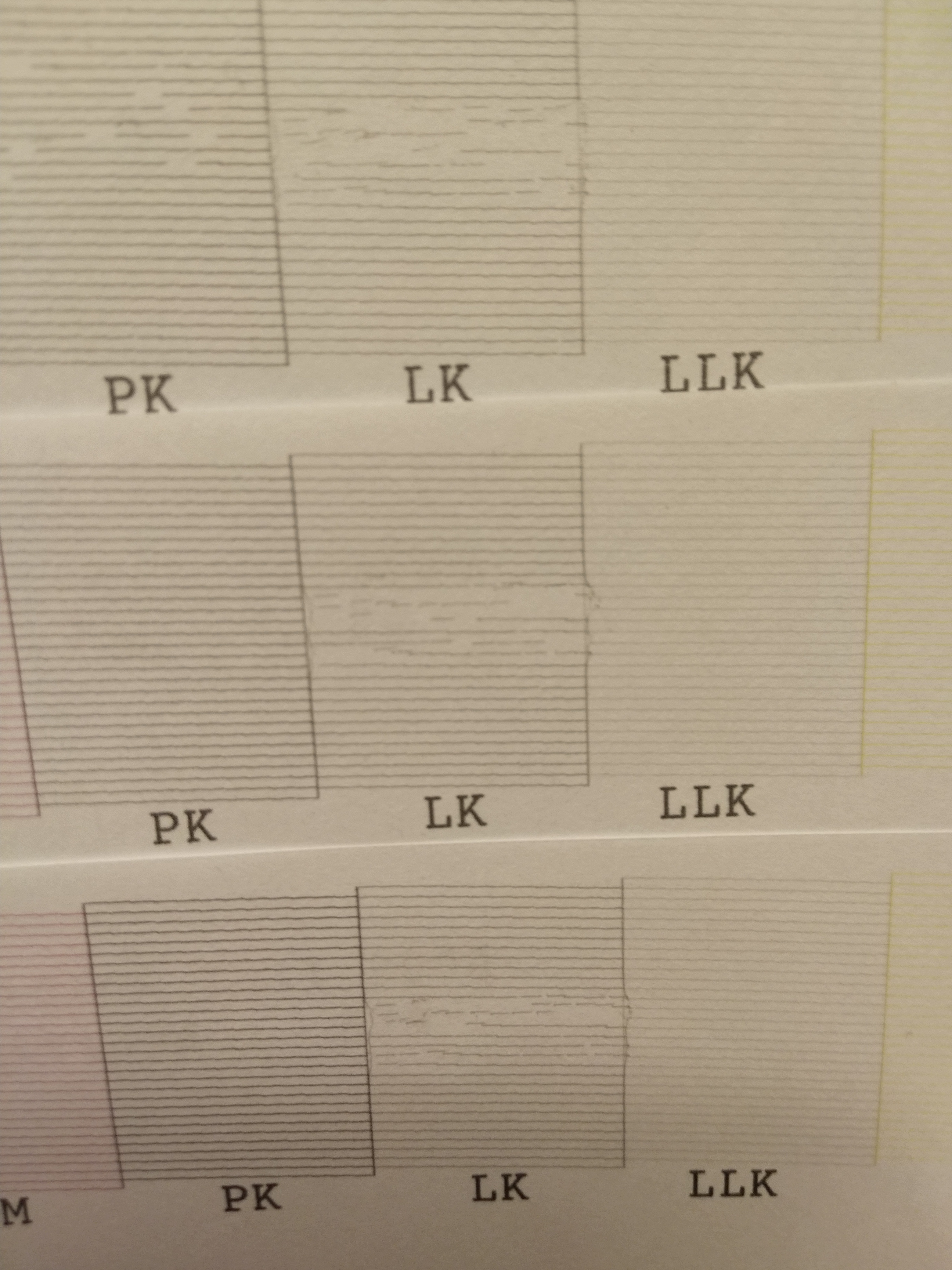

Please see the attached image. Printed on cheaper Canson 8.5x11 (cut-sheet) paper.

So I bought a 7890 off a guy for $100. He said the black channel was clogged, but hadn’t tried any fixes other than cleans/power cleans. I knew piezo inks were a thing, and I like getting my hands dirty - I decided to take on the project…

IF I can save this thing, I would love to use it as a full color printer. If not, though, as a wet-process photographer the ability to print my own negatives is very interesting.

Here is what I have done so far:

- Put in new black ink so that I can do cleanings etc. (was out of Photo Black when I got it)

- Did 3 normal cleanings

- 1 Power clean

- 1 SS clean.

As I progressed through these cleanings, all channels except black have gone perfect. Black improved greatly over the course of the cleanings but still has some clogs. I think there may be a couple deflecting nozzles as well, but given the pattern it is hard for me to say for sure.

Despite all of this, the print comes out as pictured below.

I’ve also done a bunch of googling, and tried adjustments regarding platen gaps, feed adjustments turning off high speed, etc. The only thing that seems to make a difference is decrease the feed adjustment setting. When I get down to -0.70, -0.50, -0.40, it does remove the banding, but the picture sharpness drops through the floor - not acceptable! My theory is that this adjustment is just “blurring” the lines so you don’t notice them - just causing the ink to be spread out differently.

What has me stumped is that the image looks great at the beginning and end of the picture, all the banding is in the middle. Could it be that there are enough nozzles working to print fine, but that the feed mechanism is messed up?

So here is my question - nozzle checks tell me there is a clog, but is this banding directly related to that clog, or is there something else happening? I am trying to mitigate expenditures while I work my way toward a “cheap printer”, and if a round of piezo flush isn’t going to address the issue, or if there is some other issue I should be addressing first, it would be great to know!

Essentially, should I jump straight to Piezo inks, or is there any hope that piezo flush will fix this printer?

Also worth noting that the print was done on cut-sheet paper, and I haven’t tried printing from a roll.

Thanks in advance for any help that can be given!