John,

Make sure if you do this not to cover the cart vent holes!

Chris

John,

Make sure if you do this not to cover the cart vent holes!

Chris

I will be sure not to, thanks!

Hey everyone. You have to depress the spring-loaded lock (pinch it back) before putting the cartridge in. After the cartridge is in all the way, let go and the cartridge will be locked under the cartridge lock bar.

Forcing these cartridges in and out of the printer without re-tracting the spring loaded tab lock can damage the cartridge and/or lead to all the problems listed in this thread.

best,

Walker

Hi Walker,

I always pinch the spring-loaded lock when I insert a cartridge. But additional downward pressure is needed for the tongue of the lock to engage the cartridge lock bar, and it only engages the bar by a hairbreadth! The tolerances of the locking mechanism are too tight. I’m an engineer who has worked around mechanical equipment my entire career and I know this is not the way a locking mechanism should feel. Epson cartridges snap in without additional downward pressure, give a distinctive “click” and gave me perfect nozzle checks every time!

I’m going to keep trying. I ordered a 700ml bottle of PiezoFlush. I’ll be patient and do purge patterns as Keith Schreiber and others have suggested. If I can’t solve the problem, I’ll put my P400 up for sale and buy a printer with more of a track record. I almost bought a 1430, but was convinced I should go for the P400 because it’s the latest and greatest. It is nifty printer, but IMHO the IJM cartridges need refinement.

I respectfully disagree. The photo below shows the last 2 weeks of R&D P400 cartridges. I use about 1 set per week (I have used now well over 300 or 400 of these cartridges). I haven’t had lock issues, clog issues, or any other issues really beside accidentally tipping the carts over and then contaminating the air inlet filter with ink on occasion (usually after I’m done with a cart and it’s outside of the printer. You can see the ones that have black in the air inlet area.)

The “give” (or slow push-back is the way I like to think of it) that you are feeling is the inlet spike and ball spring. It’s a very heavy spring. It’s designed that way to enable you to prime the cartridge if need-be (something previous small format cartridges did not allow one to do).

I have not had a single cartridge break, come apart, etc, on putting it in or out of a printer. I’ve had one customer with a leaking cartridge of the thousands that we have sold and we were able to replace that cartridge promptly. I had another customer who had clog issues on an R2000 with similar carts but with hundreds of emails back and forth I came to the determination that it was a printer fluke.

I think what you need is a few spare cartridges. Fill them gentle, then rip the air tabs, wrap and tap, settle, put in printer, run a few cleanings (3 generally gets the new ink through the head) and you should be good.

-Walker

I got my new giant bottle of PiezoFlush and was able to continue trying to get a good nozzle check from my P400 printer.

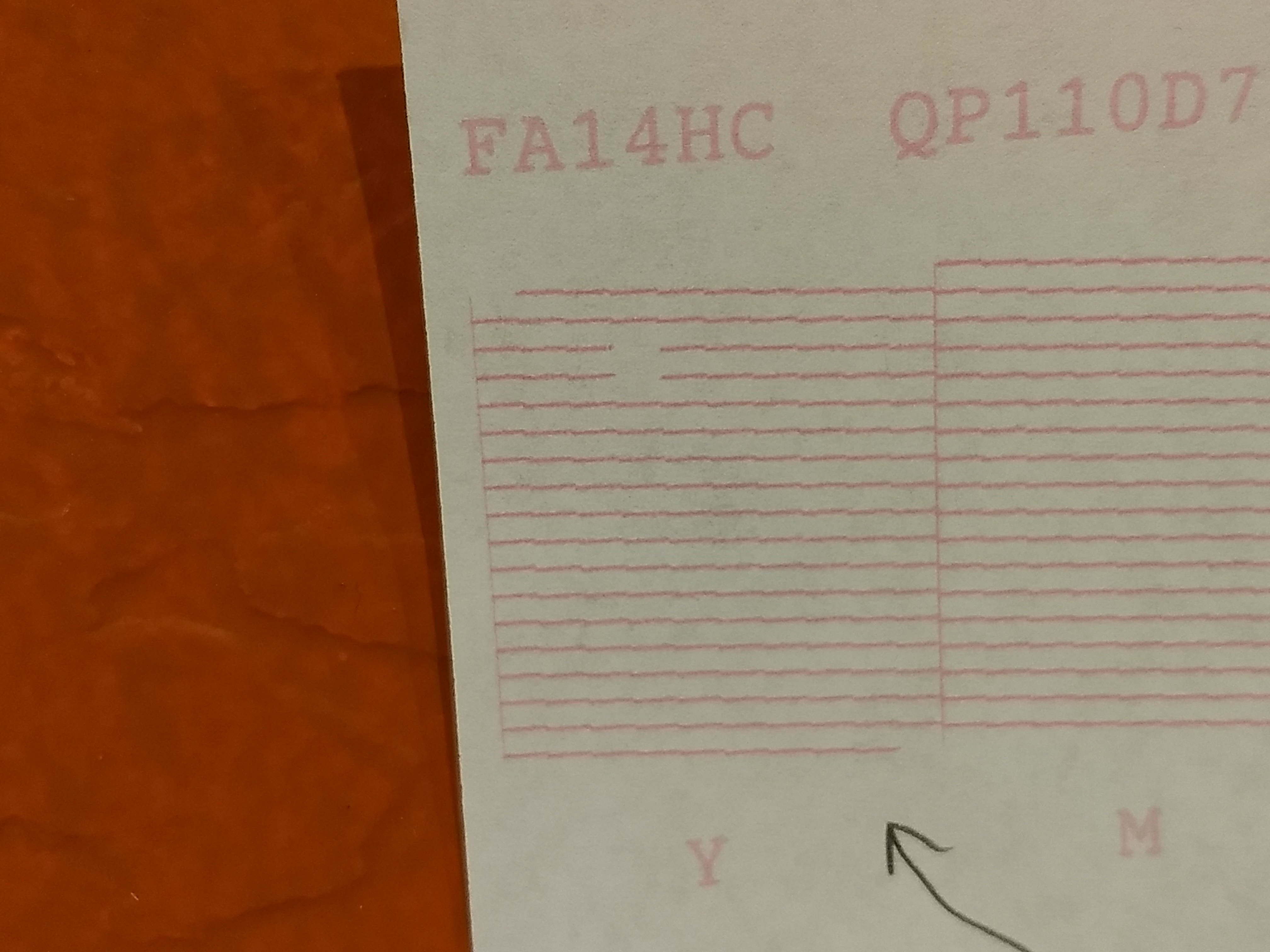

A preliminary nozzle check showed four gaps:

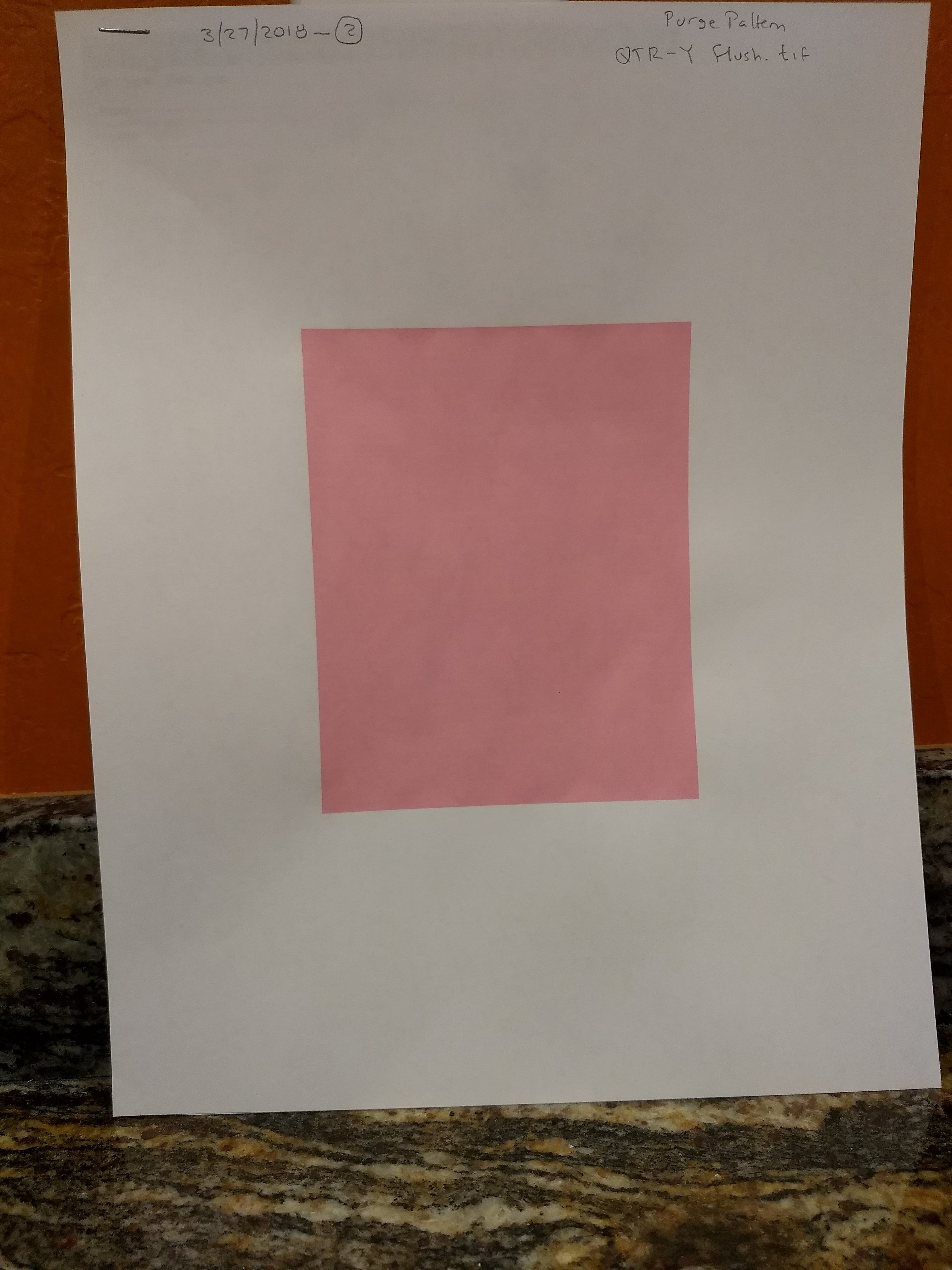

I then printed the QTR-Y.tif purge pattern IN CALIBRATION MODE using QuadR2000-PiezoDN-P2 as the Printer model. It is hard to tell if there’s anything wrong with the printout. It’s just a solid pink square.

Incidentally, the Windows instructions for printing purge patterns say to select 50-80% saturation if printing on typewriter paper (which I was using). I do not see a “saturation” parameter in QTRGui, so I set the Ink Calibration parameter to 50%, guessing that is what is meant.

After printing the purge pattern, I did another nozzle check. There’s no difference whatsoever: I see the same four gaps!

So should I print another purge pattern? A bigger purge pattern? (this one was scald to 50%). Or keep printing purge patterns until the gaps are gone?

Don Messec (who is sponsoring the Jon Cone workshop in June), suggested that my P400 Y and C cartridges might be defective. Can I get replacements for just those two cartridges? Since they’re the only ones with bad nozzle checks, and have given bad nozzle checks consistently from the moment I put them in, I think it’s worth trying.

Incidentally, I wanted to contact technical support to ask this question. But the technical support page only explains how to find your customer number, but doesn’t say exactly what to do with it. Is the proper way to get technical support simply to post to this forum, giving your customer number? If so, here’s my customer number: C35770. Seems odd, but there it is!

After several several prints and trial and error I am convinced that my issue is withy printer. Not the IJM ink carts. I think that with the mass production of the epson printers that maybe 1 out of how many ever may have a tooling issue in the cart carrier. I have found that if I do at least one printhead cleaning possibly two before printing each day then everything seems to be fine. However this does not work if I remove the foam core DIY I did. I think I just have a bad printer and will deal with it until I can replace it with a P600

I’d let it sit for a while now, maybe overnight, then do it again. And yeah, the guy who wrote the QTRgui (not Roy) must have meant “saturation” instead of “calibration” on that slider.

+1, although I’ve never had a problem with Stephen Billard’s use of “calibration”, as it’s a slider you’d use when printing the ink separation page to create QTR curves the traditional way. Saturation is for colours. Perhaps he could have used density or ink load limit.

You are absolutely right, Brian, saturation is not the correct term either. Calibration Ink Limit (as it’s labeled in the Mac version of QTR) would be more accurate. In Windows it is labeled Ink Calibration which is vague and prone to cause head scratching.

Hi Keith,

I did as you suggested: I waited overnight, ran another nozzle check (got the same four gaps in Yellow as usual), and then printed a second purge pattern using QTR_Y flush.tif. This time, I scaled the pattern by 75% (up from 50%).

The pattern showed faint horizontal lines at the leading edge, followed by what looked like solid pink (it’s hard to know if it was truly “solid pink” because I haven’t seen what a clean purge pattern looks like). I was encouraged to see this, as it seemed to indicate that the purge was working. However a nozzle check afterward showed the exactly the same four gaps in Yellow as before. Grrr.

I mentioned earlier in this discussion that Cyan is also showing gaps. In fact, the gaps in Cyan are far worse than the ones in Yellow. I printed a purge pattern using QTR_C flush.tif, also at 75% scale. The pattern showed distinct horizontal lines for the first 3/16", then what looked like solid pink. Again, the purge seemed to be working. However a nozzle check afterward showed exactly the same gaps in Cyan as before.

Wait till tomorrow and repeat?

It’s interesting that the only “colors” giving bad nozzle checks are the leftmost (Yellow) and rightmost (Cyan). The six in the middle have always given clean nozzle checks. Coincidence? Or is there a possible explanation?

Someone earlier in this discussion (Walker?) suggested that I try another set of P400 cartridges. I have two sets. One is filled with piezo ink and one is filled with piezo flush. I’m using the flush set so as not to waste the ink. Do you think I should just swap in the ink cartridges in and see what happens?

Thanks for your help!

John

At this stage its hard to know what to advise. This behaviour is not supposed to happen with a new printer and the latest generation of IJM carts. If you can’t manage a good nozzle check with flush then you’d have to be incredibly lucky to get it working with ink carts, as flush is generally much easier to get working.

Over the last year or two I’ve spend a fair bit of time helping another user attempting to get an R2000 (same printer one generation earlier) working with various generations of IJM carts. Very similar symptoms on and off. I’ve had also them myself with other printers. All I can suggest is print a purge pattern or two do a nozzle check, wait a day, repeat. If after several of these then maybe one head clean and then back to purge patterns and patience. I know, it’s frustrating. As I said earlier, patience is a difficult virtue to practice.

You could also ready my lessons learned post from a few years back, but you may find it discouraging.

John - Sorry that didn’t help. All I can say is that some of these machines can be more finicky than others, both models and individual units.

Currently, I have 2 3880s and a 1430. The 3880 running OEM color inks is pretty much flawless. The 3880 running K7-Carbon is also nearly flawless for maintenance and prints on paper, but for PiezoDN negatives it produces an unacceptable level of “grain” in the highlights. I still don’t know if that something inherent in this model, or if it’s my particular unit. Evenness of dots is much improved with the beta-driver but the dots themselves are still a problem. I’m still hopeful that will be remedied in the next release.

The 1430 makes beautiful negatives, but it is much more troublesome on the maintenance side. This is my second unit. The first threw a sensor error of some sort, shortly after the warranty was up (of course), that I couldn’t solve even with assistance from Walker. I replaced it with a refurb, which has been running well so far. Both of them required a cleaning/purging routine that took several hours after being off for a week or longer. I used a CISS on the first unit, which worked well for a while, then began to drain back into the tanks whenever it was idle. An air leak at the carts or capping station probably. I use the refillable carts with the 2nd unit. They have been much more reliable. especially once I figured out a good refill routine, but still require many more cleaning cycles than the 3880s.

One thing I want to warn you about is using paper towels (including the recommended Bounty brand) for head cleaning. They shed paper fibers which can then be deposited on your negatives. I struggled with this for weeks before realizing that the dust had to be coming from the supposedly clean head. When I cleaned it with a strip of microfiber lens cleaning cloth soaked in PF it improved greatly. I mentioned this to Walker and he recommended using scanner wipes. That problem has cleared up.

Sometimes it’s really hard to know when the solution is just over the hill, and when the situation is hopeless. Several years ago I had a 3800 with one channel completely blocked. I replaced the entire ink supply system, and that printer is still being used with ConeColor inks by a friend. On the other hand, when my dear old 7600 was about 8 years old it suddenly developed a major leakage problem. I worked on it, off and on, for another 2 years before finally giving up and giving it away for parts.

Since your printer is nearly new and still in warranty, you might want to consider putting Epson inks back in and seeing about getting a replacement.

Maybe Walker will weigh in again with some more expert advice.

Keith

Brian,

Good advice. I will stick with the flush.

I printed two more purge patterns this morning, one Y and one C. This time I printed at 80% Ink Calibration on photo paper. With photo paper, it’s much easier to see the horizontal lines running the entire length of the patterns. There’s definitely no solid pink.

I did a nozzle check after printing the purge patterns. Sadly, the number of gaps had increased substantially in both Y and C. Maybe I’ll do a head cleaning tomorrow, but my experience with head cleanings has been that they make the situation even worse.

Do you think I should try doing the Epson Small Format Printer Maintenance procedure? This involves running the print head over a paper towel soaked in PiezoFlush in order to clean the underside of the print head.

I generally approach projects with a great deal of patience. This printer is now almost Two months old, and I am unable to use it. When I ordered the printer, I signed up for a Jon Cone workshop to be held in June. Now I am wondering if I should cancel that and lose my deposit. There’s no sense in taking the workshop if I’m still unable to print by then.

+100. The rule seems to be that the cheaper the printer model, the more unit-to-unit variability. Hence the issues with the R1430. The P400 is more expensive and so you’d hope there’d be less, but perhaps not. It’s still relatively inexpensive compared to other 13" models.

The new generation IJM carts are supposed to be engineered to be more tolerant of this variability but there are at least a couple of cases - John’s and the user I’ve been working with - where that doesn’t seem to be the case.

+1. Very hard to know.

I’ve struggled with what’s best to use. I don’t do DNG, so my requirements are less critical. Bounty is not generally available in this country, although a few years ago I managed to stumble across a pack in the local Costco. They’re definitely better, but not perfect. I have on occasion used a kitchen wipe product sold in this country as Chux Super Wipes. A little like a microfibre cloth. Not paper and I not likely so shed fibres or particles. I don’t believe that you can buy them in the US, at least not under that name, but since everything plus more is available in the US, you must be able to buy something similar. But I don’t think that any of this is relevant to John at the moment.

I asked Walker if he would send me replacement carts for Y and C, since they’re the only ones with problems. If the variability is in the printer (not the carts), I suspect this won’t solve the problem, but I think it’s worth trying.

On the outside chance it’s the carts and not the printer, I’m asking inkjetmall if they’ll send me two replacement Y and C carts to try. If that doesn’t fix the problem, I’ll put the Epson inks back in, as you suggested.

Thank you for your help and good advice throughout this discussion!

Brian,

I wholeheartedly agree with your statement “You can’t operate like this.”

Regarding the possibility of manufacturing variation in the print head manifold: If the Epson cartridges gave good nozzle checks and the IJM cartridges don’t, then doesn’t it follow that the variation must be in the cartridges, not the printer?

Notice how the IJM carts fit:

The gaps between carts are irregular and the carts are not perfectly parallel.

Now see how snugly the Epson carts fit:

To see why, take a look at the next image.

The IJM carts are clearly narrower than the Epson carts. The difference amounts to 5/32" over eight cartridges, or a little less than 1/32" between carts. This is enough for the carts to wiggle laterally within the spacers at the bottom of the carriage.

We’re sending Y and C. (BTW, I did not respond during the weekend as I was not working this weekend.)

BUT, I suggest doing a small part of the scientific process.

best regards,

Walker