What is going on? Hard to say. There’s no real answer, or putting that another way, there are quite a few possible answers, and it’s hard to know which one it might be.

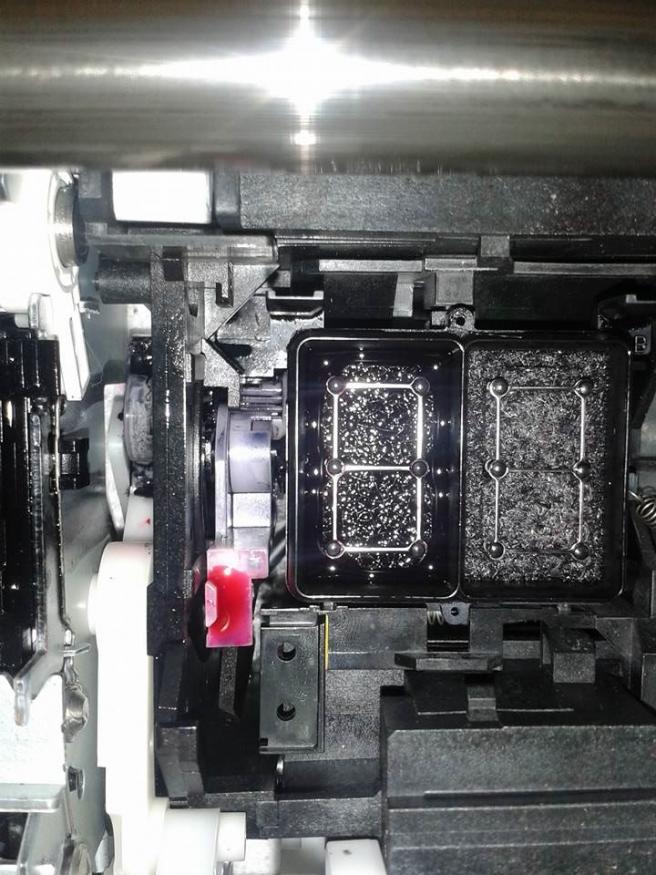

I am having a similar problem with my R1900, although my recurring problem is misfiring nozzles rather than a simple gap. This is physically virtually identical to the R2880, except it runs a different OEM inkset. I’m using it for Piezography2. I’m fortunate that since the problem channel is also Yellow (just a coincidence), which holds shade 1 for gloss, and I’m printing on matte mostly, I can just leave the flush cart in there. I’m yet to see if this made any difference. If you try this, it may be worth pausing printing and leaving the cart in there for a while, like several days, and maybe up to a week. When trying to get the gremlins out of a printer, patience is often a virtue.

I’ve had a problem like yours in the past with this printer, and at that time the inks and carts were both a little old. So I replaced them and the problem went away. If that applies to you then it’s worth considering. But as you can see in that thread, my current Y channel already holds new ink in a new cart, and there are only two possibilities that I can think of. One is that I haven’t done the cleaning routine, as recommended by Dana, well enough. Two is that the print head is on the way out, after five years.

I also have an R2880 that I use for colour work, rarely. It sits with flush carts most of the time. When I put the flush carts in after a period of printing, I find that after the printer does the mandatory head clean, and I print a couple of those calibration pages, there are still traces of colour. Another head clean removes all that. So that’s the routine I’d recommend if you put a flush cart in the Y slot - mandatory clean, purge (calibration) patterns, and an second head clean. When I put the colour inks back in, generally the mandatory head clean is sufficient.

It’s not clear what you did when declared problem solved. If you flushed the Y channel with the cleaning kit then it’s not clear that a flush cart is going to help, although it may. There’s also the full printer cleaning routine, but once you’ve done all that, and your inks and carts are fresh, and the problem continues to return, then I’m out of ideas.