So we should buy up all we can while we can?

Mould-made fine art paper from Europe is and has always been very seasonal. These are papers that are formed in traditional papermaking equipment using cotton rag and linters and almost always local spring water. The mills are almost always situated by the water source which is how they came to be in the first place. So Winter made paper is different than Summer made paper, etc. The quality of the water changes dramatically in the spring during the melts, and in the winter when its clearest, etc… And this has an effect on the formation of the sheet. It is relevant. The papers are coated for inkjet (usually at a different facility). This coating changes frequently due to raw ingredients… So paper is more changeable than inks.

When you find a sheet (batch#) that you really really like - it is wise to buy a supply of it. It stabilizes a studio, or a series of work, or possible an effect that can not be duplicated, etc … In our case, Cone Editions is printing for clients who store their images with us and request reprints. So we often buy enough paper to last years - so that we do not need to reproof. Because we are manufacturing our own inks - we have stabilized that portion which we would not have control over if using OEM inks (which change occasionally). So we try and stabilize our output as much as we can for as long as we can. Reproofing is time consuming and expensive. For every print on demand project we keep a match print (signed BAT proof).

This is and how it always has been in inkjet printing since the early days of the IRIS 3047. In the early 1990s, studios began trading paper batches and hoarding certain batches of Somerset Velvet uncoated. There was at one time, a list going around through the studios we had setup, for trading batches of paper. In those days, color management was via making neutral from CMYK rather than ICCs (which were not yet in practice). Today it is easier to make a new profile or a linearization when a paper changes dramatically. But, if the coating or the base changes so dramatically that the media itself is less desirable - then one rues the opportunity missed to hoard it. Hoarding is expensive. But - making art is expensive.

I would say that with discounts available in bulk purchasing, that it is wise to buy at least a years worth of media by batch# if you find a sheet that you really like. Chances are it will change. This may actually be easier for the occasional printmaker - than for a studio that produces 1000 sheets a month. Safe storage becomes an issue. Should be cool and dry (and no mice!)

I want to add that we liked the original Exhibition Fiber paper because of the whiteness, which is one of the main reasons we don’t like the new warm version.

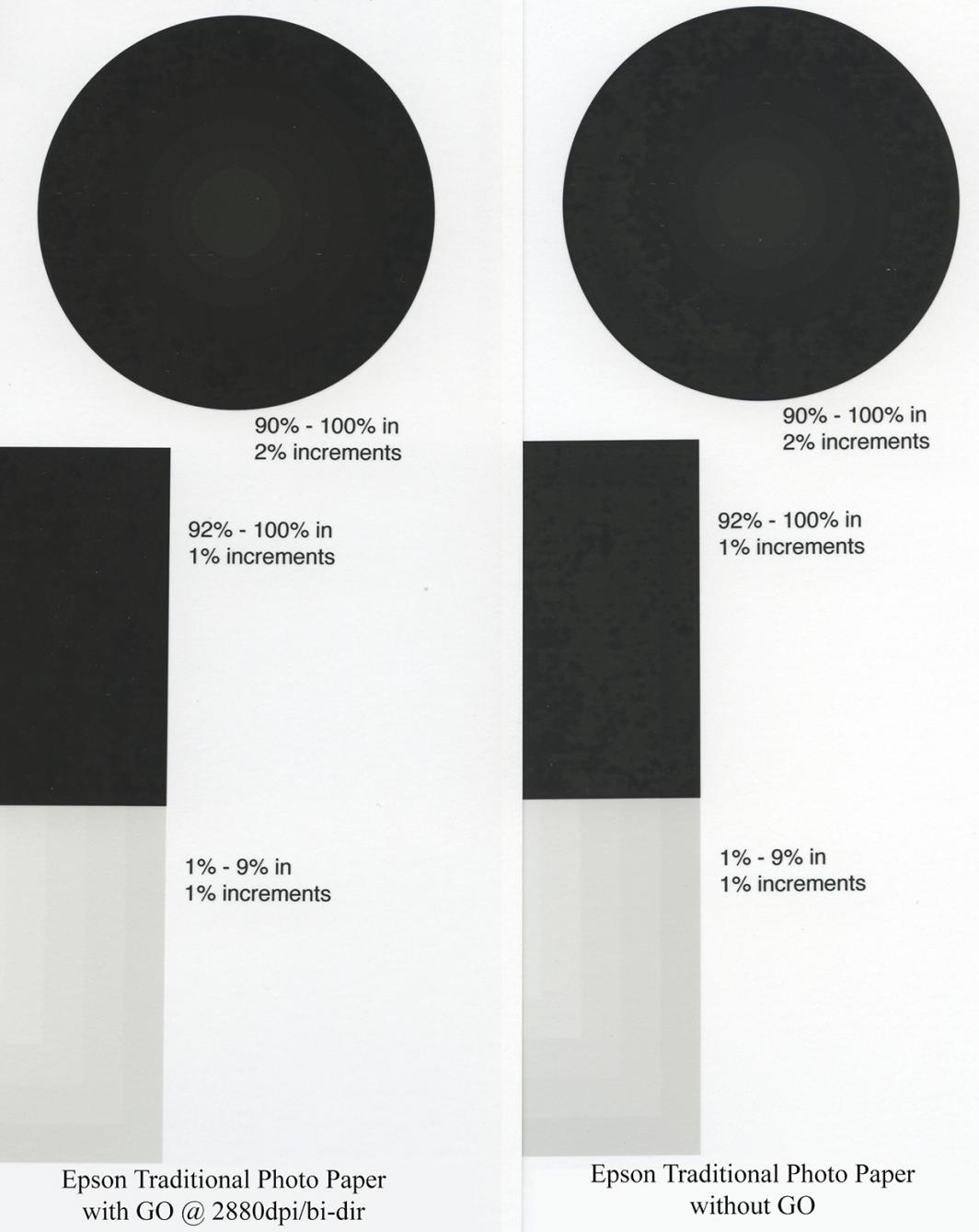

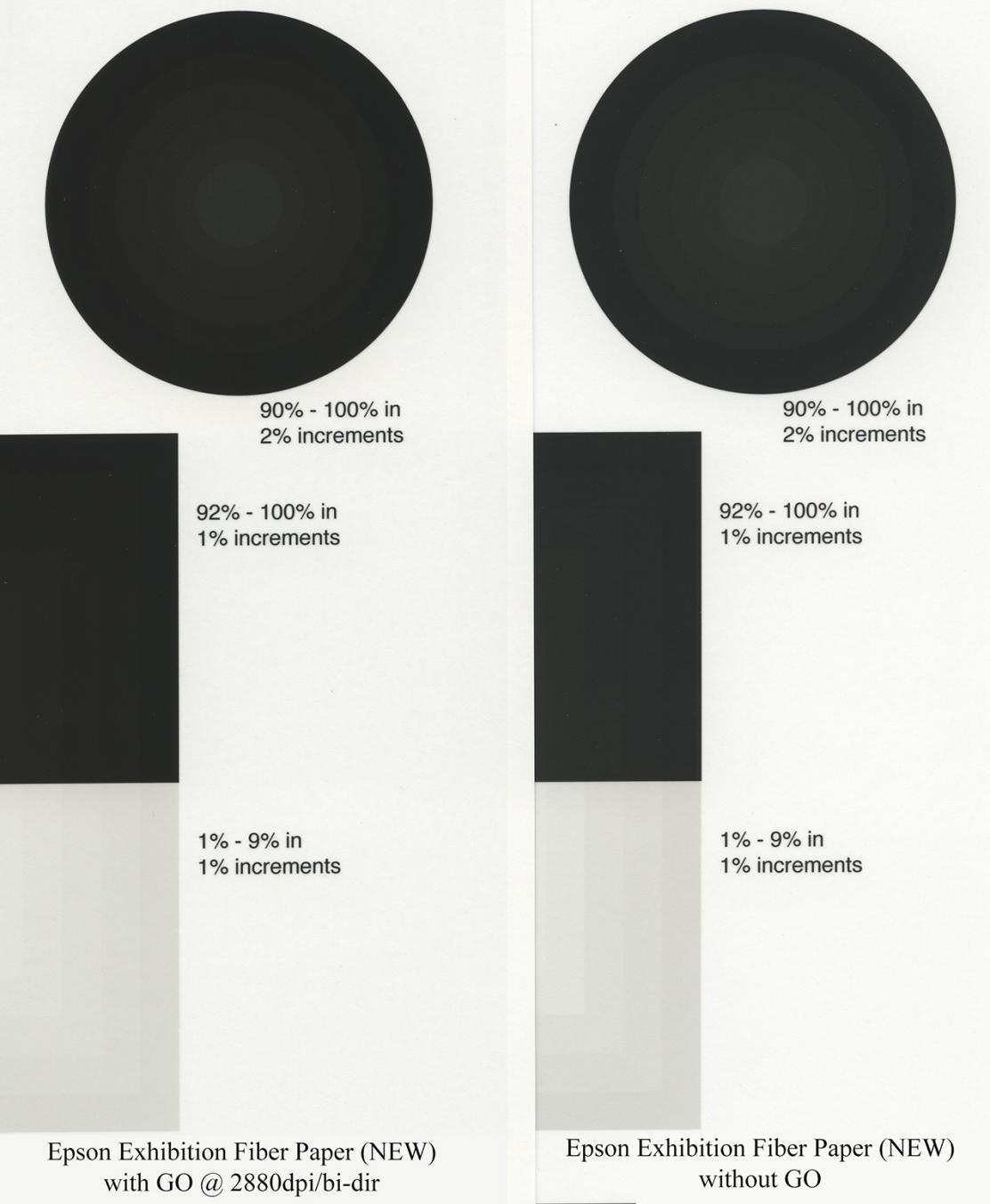

Regarding mottling in shadows, the new paper is better than the old/white version (I see NO mottling with the new/warm paper). The new/warm paper looks good with GO, but is flat/not very glossy without GO (which would effect people printing with color inks without GO). Mottling is very bad on old/white ExFiber without GO, and still present but much better after printing GO (though this seems to come and go, I think depending on temp +/or humidity levels, I’ve printed on the old/white EEF without mottling over the years, though my tests today are mottling- and the current conditions are 73F and 36% H).

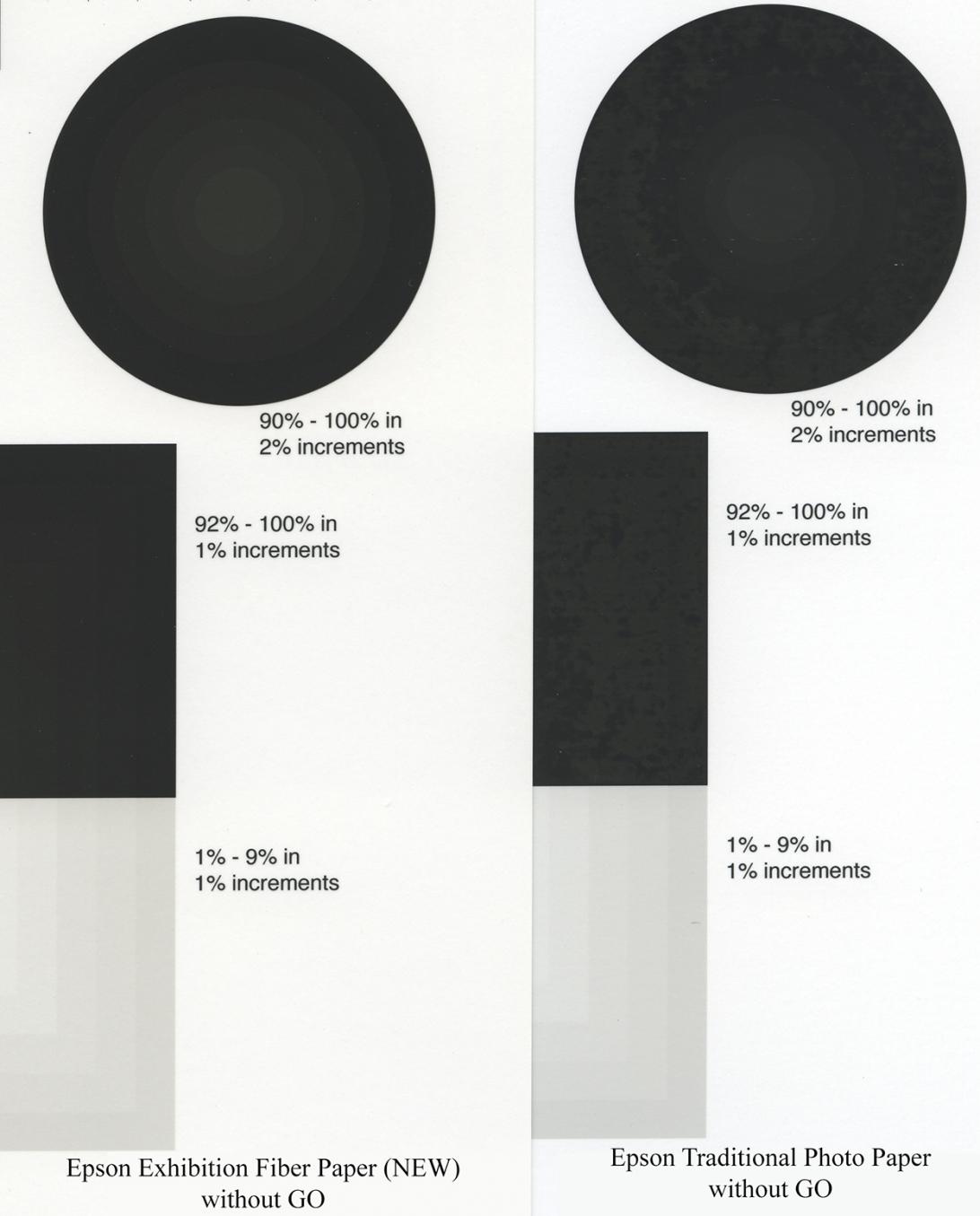

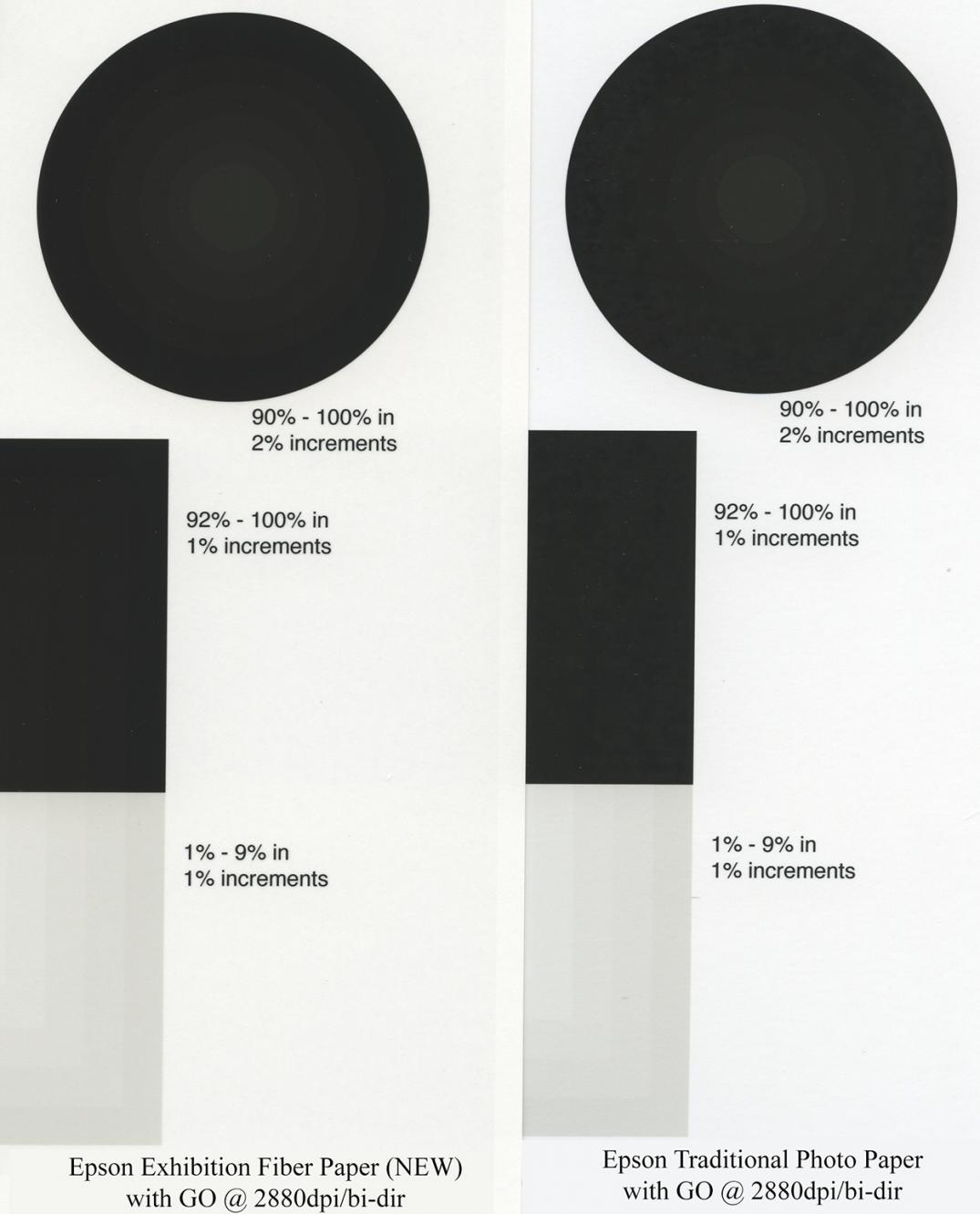

Here are a few scans showing the paper white and mottling differences with Traditional Photo Paper (from Jeff G, which is the same as the OLD/white Exhibition Fiber paper) and NEW/warm Exhibition Fiber Paper. NOTE: each scan is labeled at the bottom with the paper/setting:

Thanks Dana!

Thanks to both of you. This thread has been rolling along since March 22. I’ve certainly learned a lot along the way with it. That’s quite a difference between the same paper.

I echo Jeff’s thanks.

The big news for me in this is the mottling you get now with TPP when you didn’t back in post #45. Back then, we concluded that the paper wasn’t the problem. Something else must have been causing our mottling. But now it is the culprit.

What is going on with this paper (old version)? How could you (IJM) print for clients with it when you get such a variable outcome? I suppose it’s still possible that TPP and old EEF aren’t exactly the same, although I don’t see any evidence for that in any of the above.

Jeff’s initial box of A4 TPP has gone. I bought a second to try it out for colour work, and only did a few Piezo prints on it using the remapped P2 curves out of an obsessive interest to understand what might have been causing our mottling. When there was none initially using P2, we conducted as wide a range of tests as we could, reported in post #55.

I am disinclined to use a paper for Piezo when I can’t predict how it’s going to behave, and I don’t understand what is driving the differences. Given these IJM experiences, it could still emerge when using the P2 curves.

Jeff - when you’re next in at our normal supplier, perhaps you could ask them if they know of any recent changes in TPP, noting that there seems to be quite a dramatic change in US-sourced EEF.

On the subject of old EEF and new EEF, this post was interesting:

The poster runs a print studio and does a lot of printing, so speaks from some experience.

EEF certainly is their most “tweaky” paper. I stopped printing on it long ago when running labs in Chicago because of the variability issues with EEF . . . . Glad Epson is using platine as their main ef paper now.

cheers,

W

If you’re referring to Epson Legacy Platine, do you have a view on whether this is just Canson Platine rebranded, as suggested/claimed on Lula, and ditto for the other new Epson papers?

After this experience, I have abandoned all Epson papers other than EEM. Having also been told that the paper can be different from region to region, I lost all interest. I’ve always been wary of buying paper from printer manufacturers, and this is a good example of why you shouldn’t.

I’m under NDA so I can’t confirm or deny if it’s (canson) platine or not. So I’m just going to call it “Platine.” ![]()

My all time favourite NDA was the one where I had to deny any knowledge of the NDA.