I was in the process of putting my 9800 into storage with Piezoflush carts when a sensor chip broke and the printer wouldn’t recognise any cartridges.

Being 500km away from a service agent and the printer too big for my car, it has taken 9 months to get it “repaired”

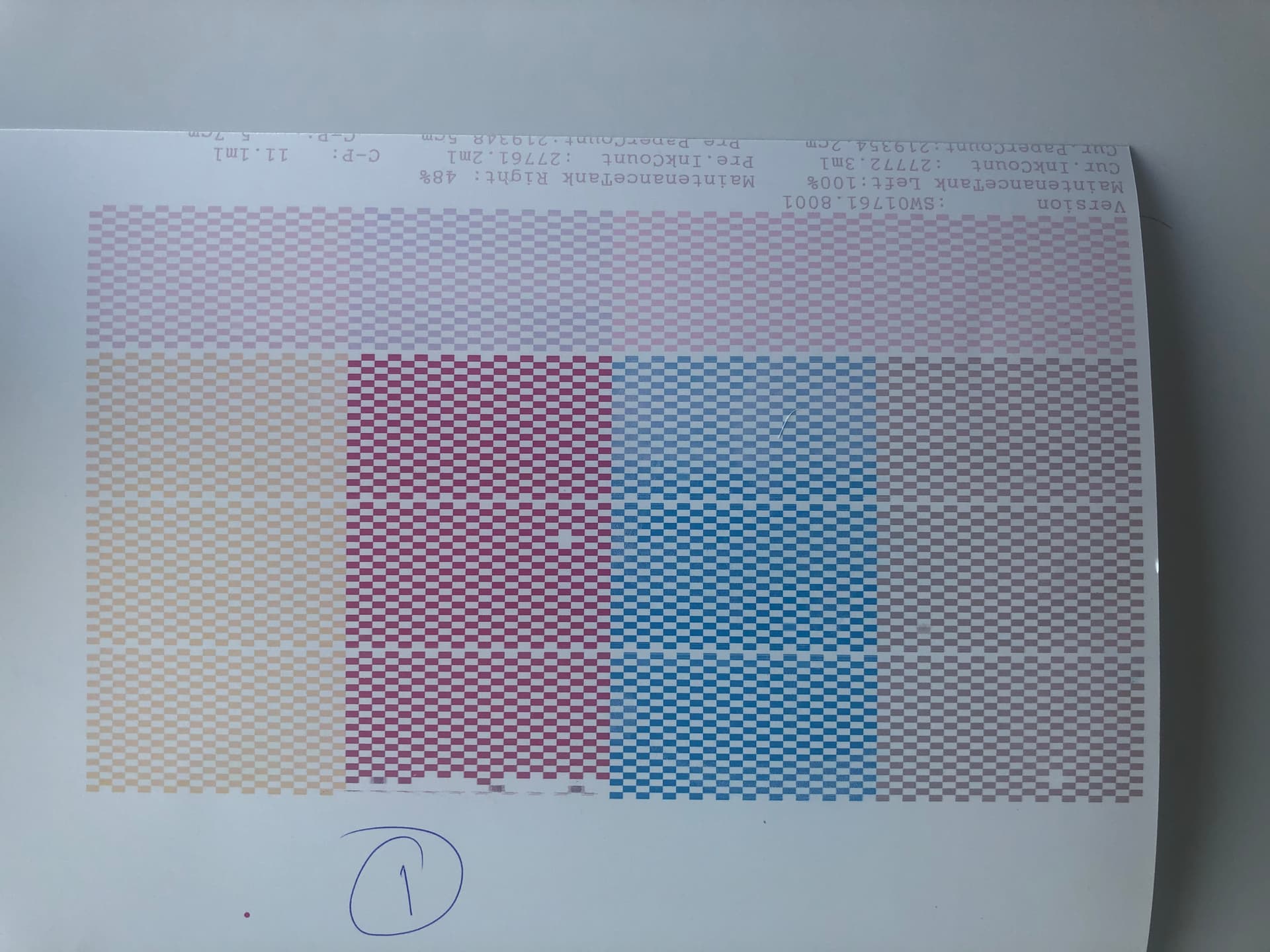

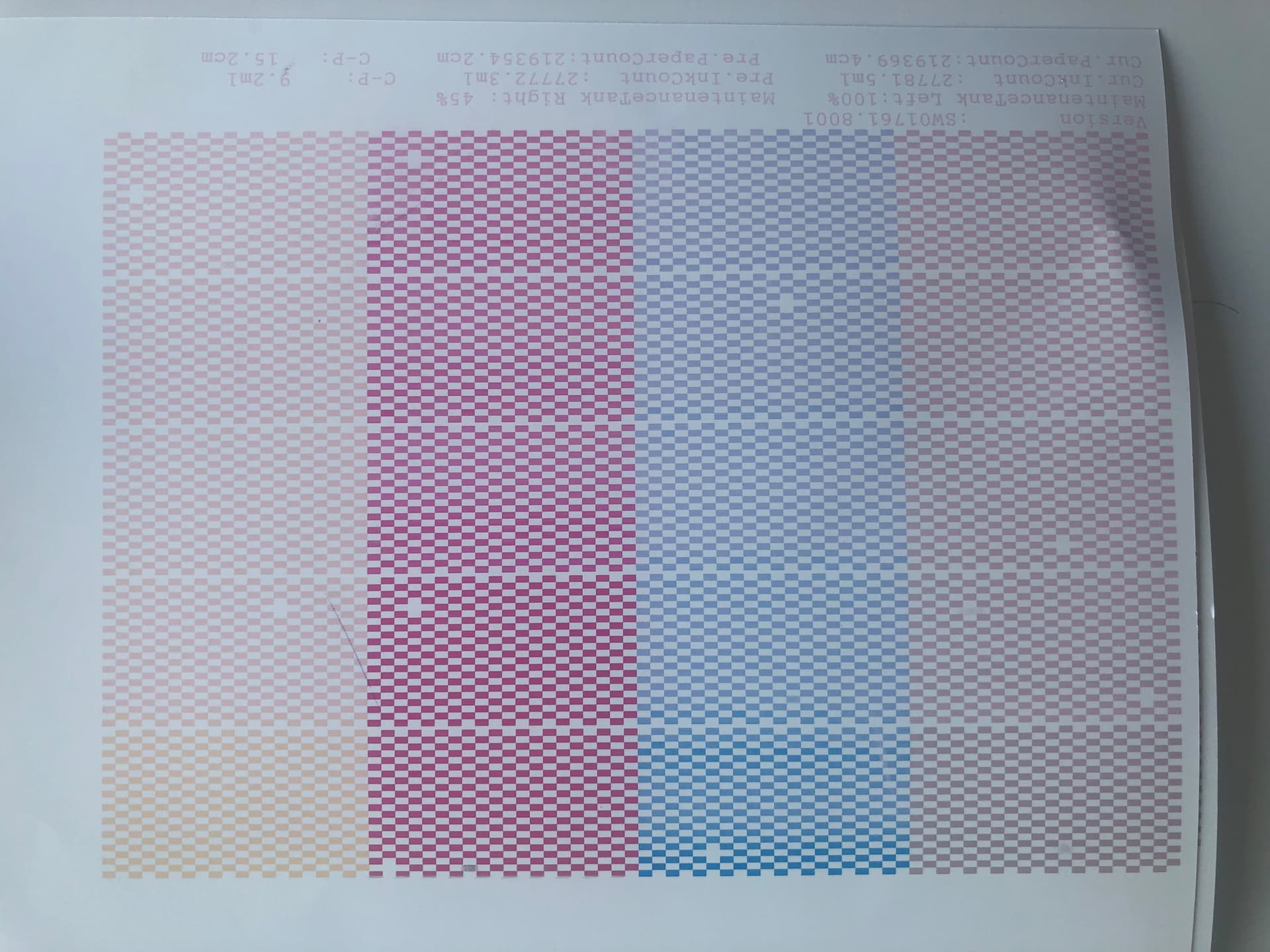

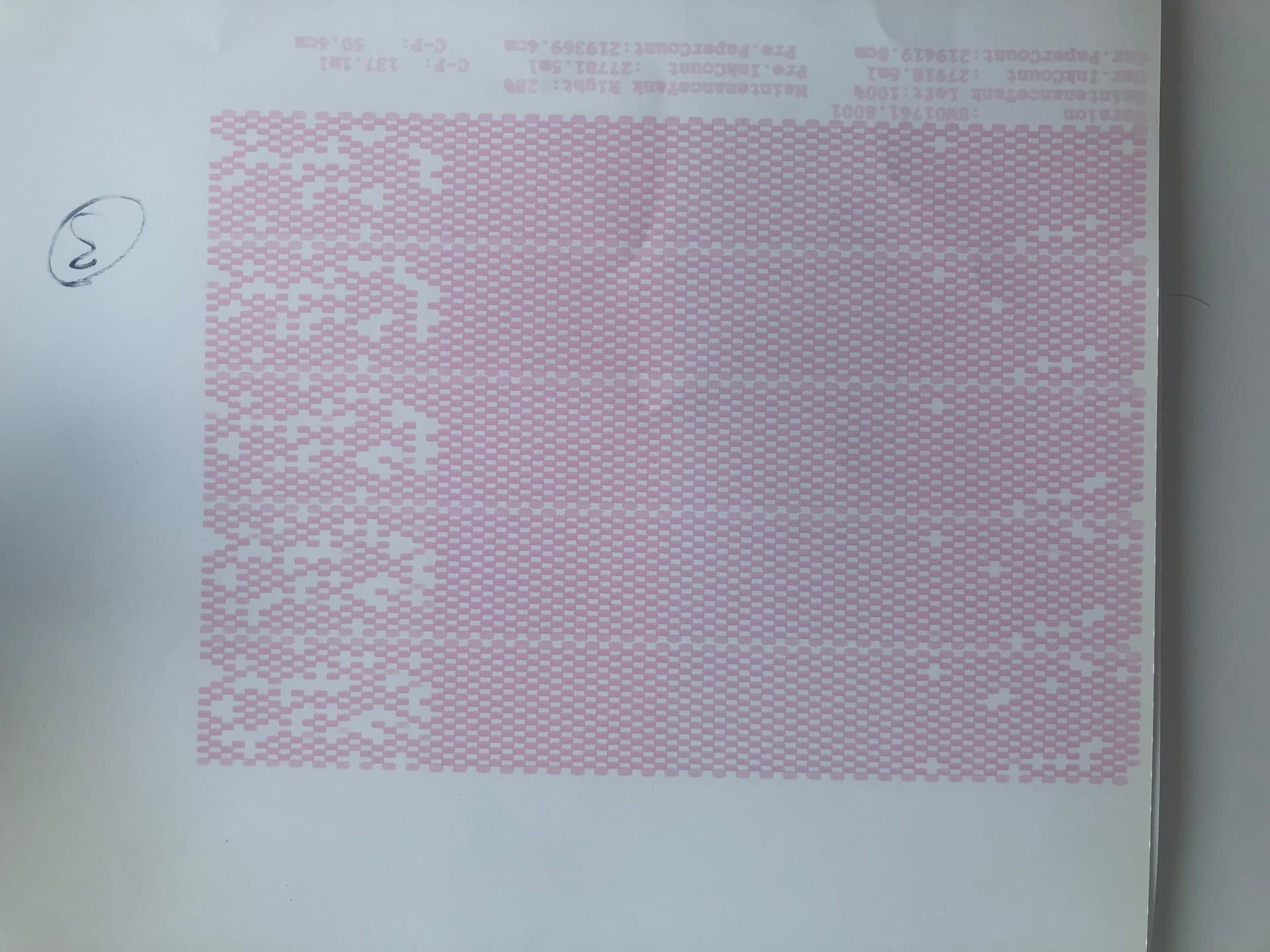

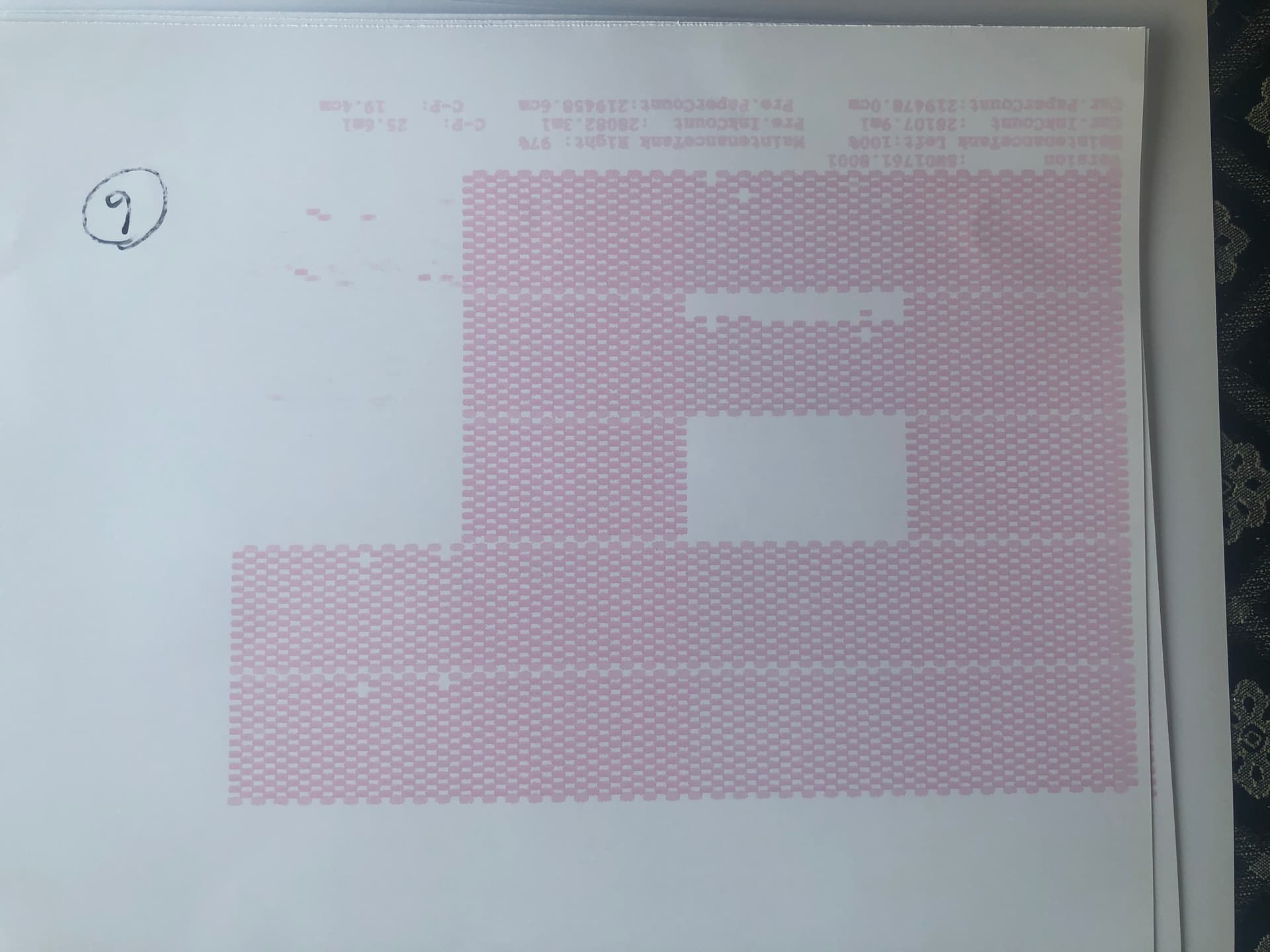

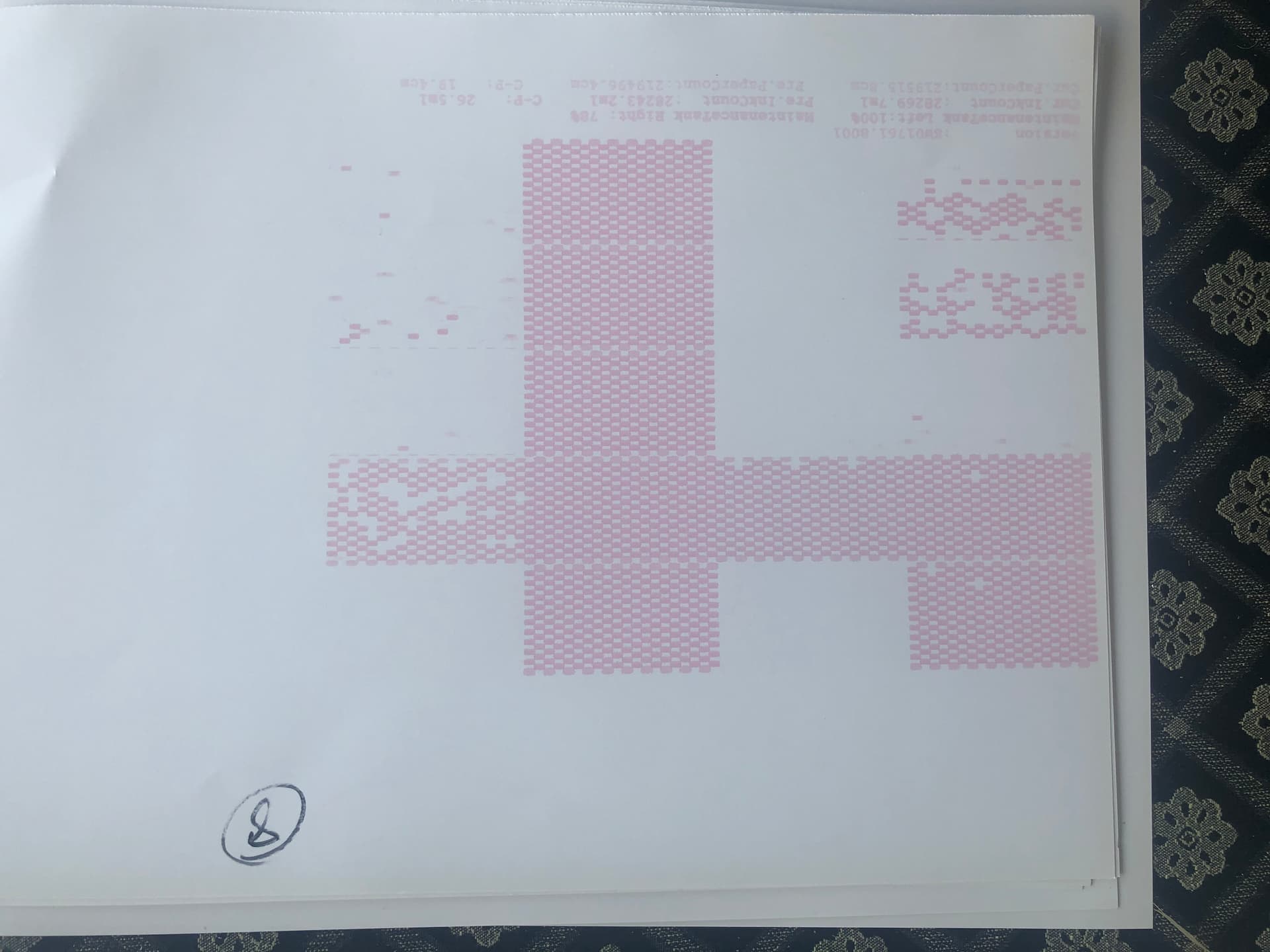

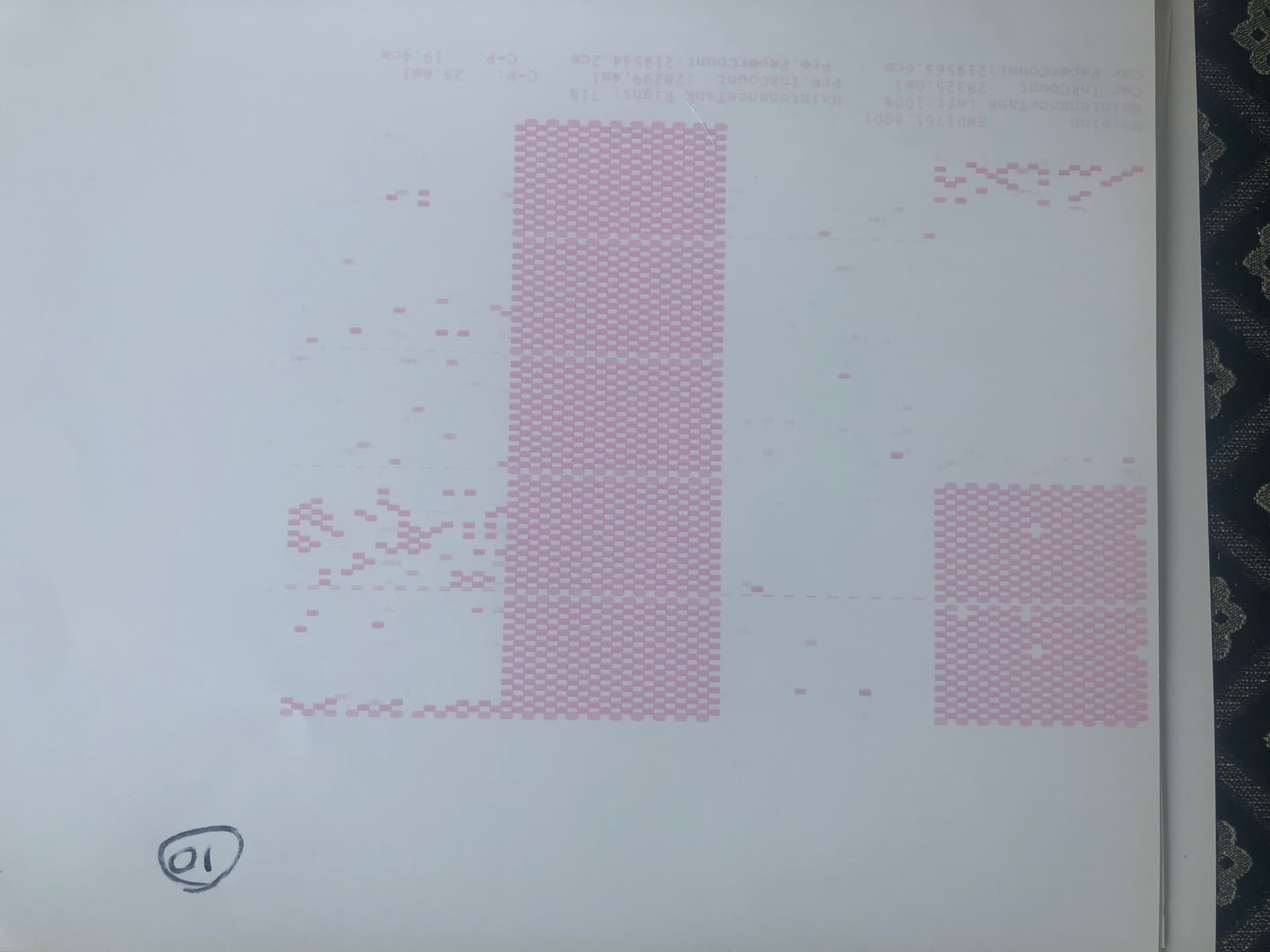

Now with the PZF installed, test prints/nozzle checks stated off well then went progressively pear shaped, see attached images to show te progressive blocks.

I have cleaned the capping station, waste box, wiper blade and done cleaning cycles and power cleans judiciously.

I noted that after the service there were several air bubbles in the ink lines, one was 13 cm long but appear to have gone now.

Does this look like time to replace dampers or the entire head assembly?

the good news is that my 7880’s, 3800 and 3880 are still chugging alone with Piezo Pro and Cone Colour in them!