I’m running into some issues that might best be resolved by comparing results with others.

Is anyone using the WM shade 1 Opaque black, and an x880 printer, that hopefully also has a device to measure density?

An x800 would work too, I think densities are pretty similar.

And Dana, if this would best be done with you, what is the best method for correspondence?

I don’t know if it’s a support issue or not yet.

Thanks,

Tyler

I am using WM Shade 1 Opaque black, or I will be when I pull the plush carts out and put the ink carts back in (I was away for 6 weeks). I have an i1 photo, and the Measure Tool on W7. However I am using an R1900, as you used to for mixing inks IIRC. It’s supposed to be physically almost the same printer as my colour R2880, but it uses different K7 curves. So if you’re looking to test a specific x800 curve then I probably can’t help, but otherwise I might be able to.

HI Brian, I appreciate the offer to correspond about this. It’s looking like I may load some of that K into my 1900 as well to help get to the bottom of this. If I do I will let you know.

What’s your timing on this Tyler? It’s just that I’m only just back from an extended trip and have returned to a backlog of commissioned material to process from before I left, plus what I shot while away. I wasn’t proposing to pull the flush carts out until I was ready to print, but I guess I could do so sooner if there was a need. FWIW, I’m mostly using SE inks with that particular shade 1.

You are aware that I’m in quite a different time zone to you? Currently GMT+10. Given that, there may be more efficient ways to communicate than the IJM forum. Send me a PM if that’s of interest.

What’s the nature of your problem? It was partly on your recommendation that I switched to WNO1.

I’m at least a week out before I can get to this and even then may need no correspondence… I’ll PM you when I’m getting into it, you can proceed with me or not, at your convenience, I appreciate your interest. I’ve been using that K ink since it came out and would still recommend it. I may have a printer problem, I’ve had some big density variations but due to other issues and have had different K inks in there, as well as a damper replacement, so really need to pin things down. I’m probably premature asking here…

It could very well be loading some into my 1900 again may reveal a lot, whether I compare things with you or not. If and when it happens it would simply be printing out the calibration chart in calibration mode and measuring the K ink patches, so the other inks you use don’t matter.

Let me get back to you, as usual, other things divert me from solving problems…

Thanks again.

T

Your call on timing and communication channel.

Which x800 is causing you grief?

Hi Tyler~

What paper are you printing on (so I can print + measure on the same paper, for the best comparison)?

What is your issue with the black?

Please let me know and I’ll get you measurements.

Best~ Dana

Sorry for the delay on this. Hi Dana, thanks for your input on this issue. I’ve had ongoing problems with my 9880 and the black channel, and I’m thinking several unrelated things have collided…

Now that printer problems seemed to be addressed, and my dmax is still low, I’m still trying to narrow things down.

With a new batch of WN1 Opaque Black, printing the inkseparation8.tif file provided with QTR, in calibration mode, at 2880 uni, I get just 1.5 with the 9880 (new damper). Measuring just that channel alone.

Same exact test printout with my 1900 yields 1.47, as opposed to MPS1 which is nearly 1.6 in the same printer, different cart, same printout. I’m trying to use the 1900 to help pin this down.

These results, in my experience are low.The paper is Canson Rag Photographique.

I began trouble shooting this after my long established StudioPrint environments (using WN1), the dmax’s dropped dramatically around 0.1, more or less depending on paper and the other inks in the environment.

History- After bad K channel banding and the dmax drop, I assumed it was the damper. After replacing the damper, loading new WN1 batch, my banding is fixed but dmax remains low. This is after years of using this exact setup and ink, previously resulting in impressive dmax…

I’m not quite sure what to test next.

Tyler

This concerns me greatly. I use the same ink for the same reasons and at the moment I get the same results as you used to. My current batch is #1000809 and is due to expire soon. I just bought a large (for me) new bottle with Lot #140725 expiring Jan 2017. I do hope that I don’t have the same issue with it as you seem to be having now. My R1900 is running at present, and I have some CRP here. I could open the new bottle ahead of time and do a comparative test of the two batches. It would be rather disappointing if the latest batch of WN1 had a much lower dMax, but that might explain the discrepancies discussed in this thread. I sincerely hope not.

it’s premature to focus on the ink or batch. I have too many variables going on here, and too many things changed at once that may be contributors. Also, Jon’s point about the inks being made to work well for the Piezography curves it totally valid. My priorities are different, and so I look for characteristics of the K alone before seeing how it works in place with the other inks in my setups. My use of Jon’s inks is pretty different from any of the setups they have developed and use in house, except perhaps for Jon’s Roland and StudioPrint.

So this is why I’ve posted about this, I’m looking for more insight before coming to any conclusions about where to apply any changes or fixes.

Any dmax comparisons between a K7/QTR output system all together, and a K ink by itself, is irrelevant at this point, they behave differently. This is one reason I used the ink separation chart in calibration mode. I don’t even have a K7 set installed, just different inks in different positions for testing purposes.

Let’s wait for more input or more testing. If you want to print out the inkseparation8.tif in calibration mode, 2880, and measure the black, that might be one useful step. Let’s see what Dana has to say when she has the time as well.

T

I can see that there were multiple things going on with the 9880, but as I read your previous post, the testing you did with the R1900 was strongly suggestive that the new batch was different. Yes, I recall that the dmax when printing with a curve is generated using four or perhaps five shades, but shade 1 is one of them, and the attraction of WN1 was that it was sufficiently close to the MK shade 1 (NU1?) that it could be substituted with little impact. That was the point of using it, wasn’t it? And there must be some impact on the density of the curve-generated 100% patch if the density of shade 1 is lower. Perhaps the drop is not worth worrying about in practice. Certainly in some curves for some printers very little of shade 1 is used, but that’s less true for the R1900 curves. I’ll do the test here in the next few days, both calibration mode and curve generated with both batches on CRP.

Brian, I’d like to repeat my 1900 test, with reloaded carts, as it was done quickly. And also get verifiable input from others if possible. Your points about it’s use or attraction don’t necessarily relate to how I use it, so I can’t comment on that. All the rest here is just hand-wringing until we get more results answers, right?

Verifiable results are definitely better than hand-wringing, including measurement of the actual impact on the curve, if any. Can’t argue with that.

Brian, to ease your concerns, we test our inks constantly (meaning daily). Keeping a very close eye on lab values, as well as dmax, glossiness and durability. We test every single lot# before, after and during manufacturing of ALL of our inks, we have very high testing/quality control standards.

Every single situation is different, as tyler has explained his system is much different then yours and for this reason you have no need to jump to conclusions there is a problem with the WN1 across the board.

Dana will reply to you tyler, she knows your system/set-up and all you’ve been through to get here.

I understand that Tyler’s 9880 is a highly non-standard setup. He mixes inks for a start. But his 1900 test is unaffected by any of that. That test was a straight test of that ink, unaffected by his production system.

It’s reassuring to know of your ink testing. But in relation to WN1, there is an unresolved issue about the discrepancy between the claimed dmax for this ink on HPR in that Black is Black article, and what a number of us are / were getting in practice. The size of the discrepancy seems too large to be simply random variation in measurement. Coincidentally it does roughly match the difference in Tyler’s measurements.

I don’t particularly want to open my new 220ml bottle of WN1 ahead of schedule, but I will if Tyler can replicate that result on his R1900 then I will go ahead and test it myself.

Hi guys~

I have been out sick all week, so apologize for not responding sooner.

I’ll have a more complete response for you next week, after reviewing our numbers, but right now I will say that Warm-Neutral shade 1 was originally designed to be a opaque black for digital negatives, and was found to also work well on glossy paper, with great glossiness and dMax. It was never designed to be used on matte/rag/non-gloss media, though some people started using it that way and were happy with the results. We always use WN#1 for glossy and film printing, and NU#1 for matte/rag/non-gloss papers in our production studio. I understand the appeal to have a universal black, but even with Epson inks there is a MK and PK, and neither works great on the opposite paper type.

Best~ Dana

Hi Dana, think you for your reply and I hope you feel better soon. I won’t be able to verify my results in the 1900 until next week. The 1900 has other K7 + GO inks installed to prepare samples for an upcoming workshop. I understand WN1 not intended as a universal black, and use it for other reasons, in fact, never as a PK. I’m still trying to nail down where my problem lies, and though perhaps changing cart/channel positions in my 9880 and StudioPrint for K may be required for certainty, I’m not anxious to do that because of time and ink cost. Hopefully I can get to the bottom of this here another way. Verifying my 1900 results is a start.

Brian, I don’t see the point in loading your new batch at first for any of this. Wouldn’t numbers for your current batch be the best place to start, to compare with mine?

T

Thanks Tyler. Please do keep me posted, and let me know what I can do to help troubleshoot.

Warmly~ Dana

Still using my initial batch, I printed three bars of shade 1 on CRP in calibration mode a couple of days ago in preparation, so there has been a lot of drying time. I did three in order to average out any sample variation.

[TABLE=“width: 500”]

Luminosity

1

2

3

ave

100

16.3

16.7

16.7

16.5

95

16.2

16.3

16.5

16.3

90

16.2

16.2

16.1

16.2

85

16.2

16.1

16.2

16.2

80

16.3

16.2

16.5

16.3

75

16.8

16.7

16.9

16.8

70

17.1

17.0

17.1

17.1

65

17.9

17.5

17.6

17.7

60

18.7

18.1

18.3

18.4

55

19.5

18.8

19.0

19.1

50

20.4

19.9

20.2

20.2

[/TABLE]

[TABLE=“width: 500”]

density

1

2

3

ave

100

1.67

1.65

1.65

1.66

95

1.67

1.67

1.66

1.66

90

1.67

1.67

1.67

1.67

85

1.67

1.67

1.67

1.67

80

1.67

1.67

1.66

1.66

75

1.65

1.65

1.64

1.65

70

1.63

1.64

1.63

1.64

65

1.60

1.62

1.61

1.61

60

1.57

1.60

1.59

1.58

55

1.54

1.57

1.56

1.56

50

1.51

1.53

1.52

1.52

[/TABLE]

By way of comparison, I posted numbers on HPR here a while back. Same batch.

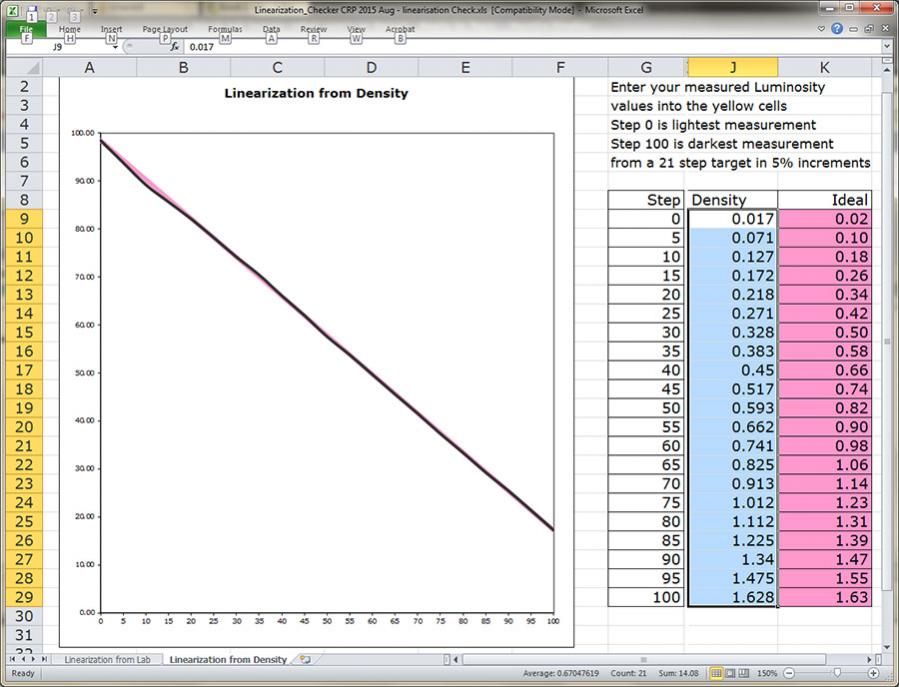

Also attached FYI is my latest linearisation check. As my R1900 is a few years old now, there has been a bit of drift (although not a large amount), and so this was relinearised using Roy Harrington’s new droplet. The dMax of the curve is not bad IMHO.

I have a spare cart here ready to load with the new batch, if needed.

.

this will help. So are the calibration numbers L values? Just want to avoid the slightest confusion