Hello,

I am having small problems with channels going and coming when performing nozzle checks on my 9880. I have not much ink left in some of the carts, and I have seen there are air bubbles in the area close to the outlet of the carts. In some cases, these bubbles extend into the small thin pipe that links the bag to the outlet. Is it normal to have these bubbles? Should I prime out the carts until they disappear? Can these bubbles be the culprit to the intermittent disappearance of nozzles at the printed checks? What might be the origin of these bubbles? (low amount of ink, or disconnecting + shaking the carts improperly?).

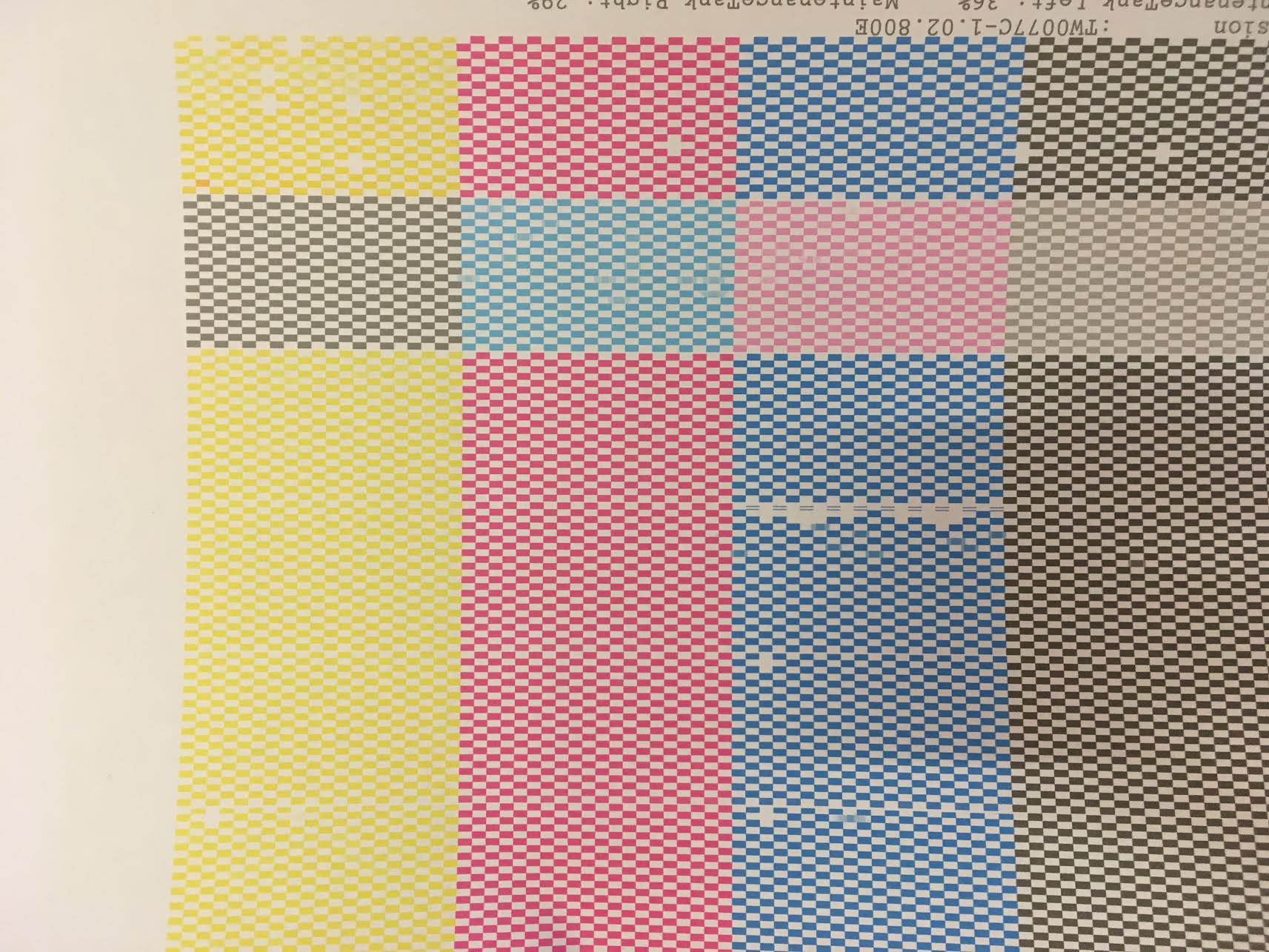

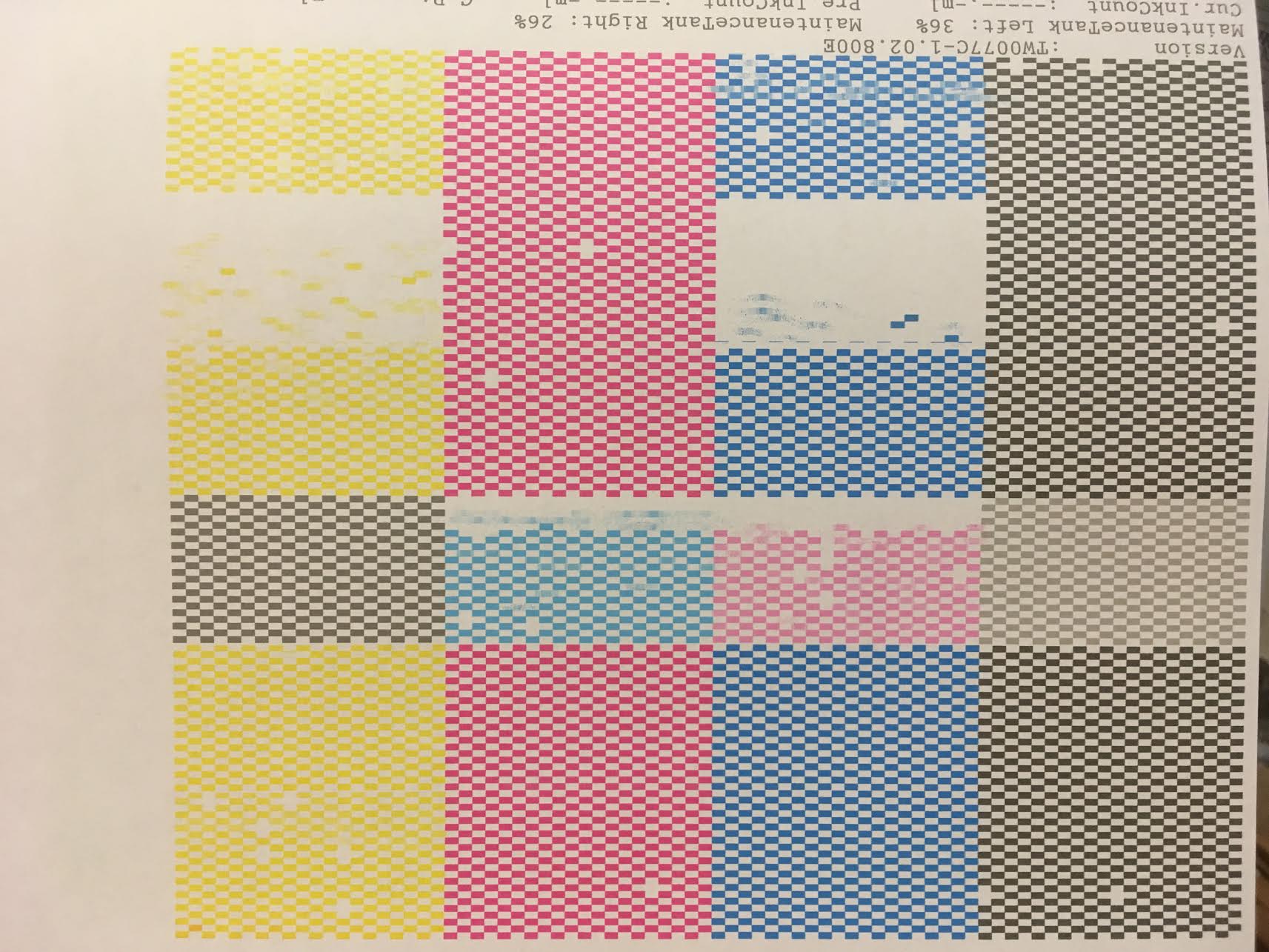

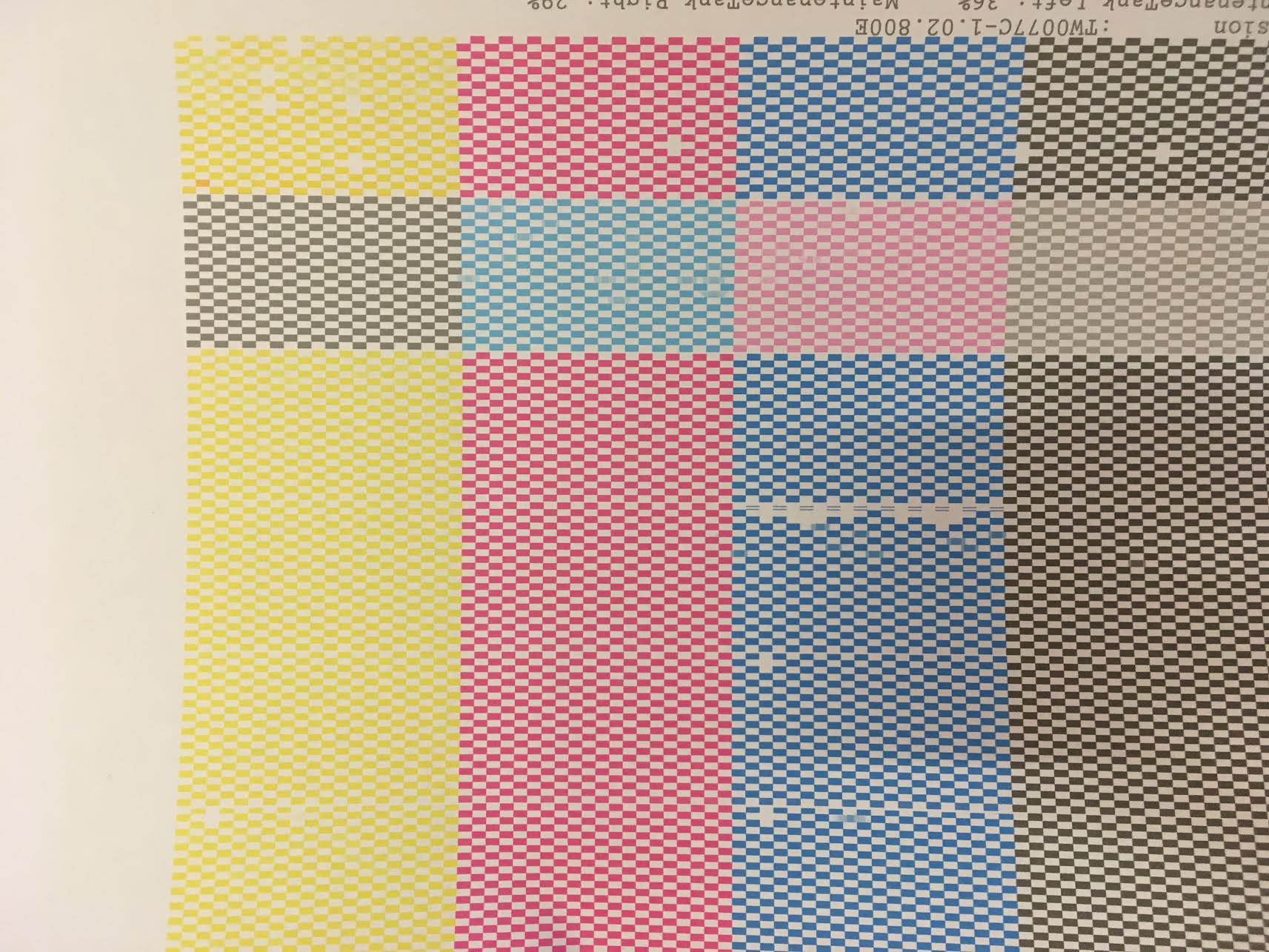

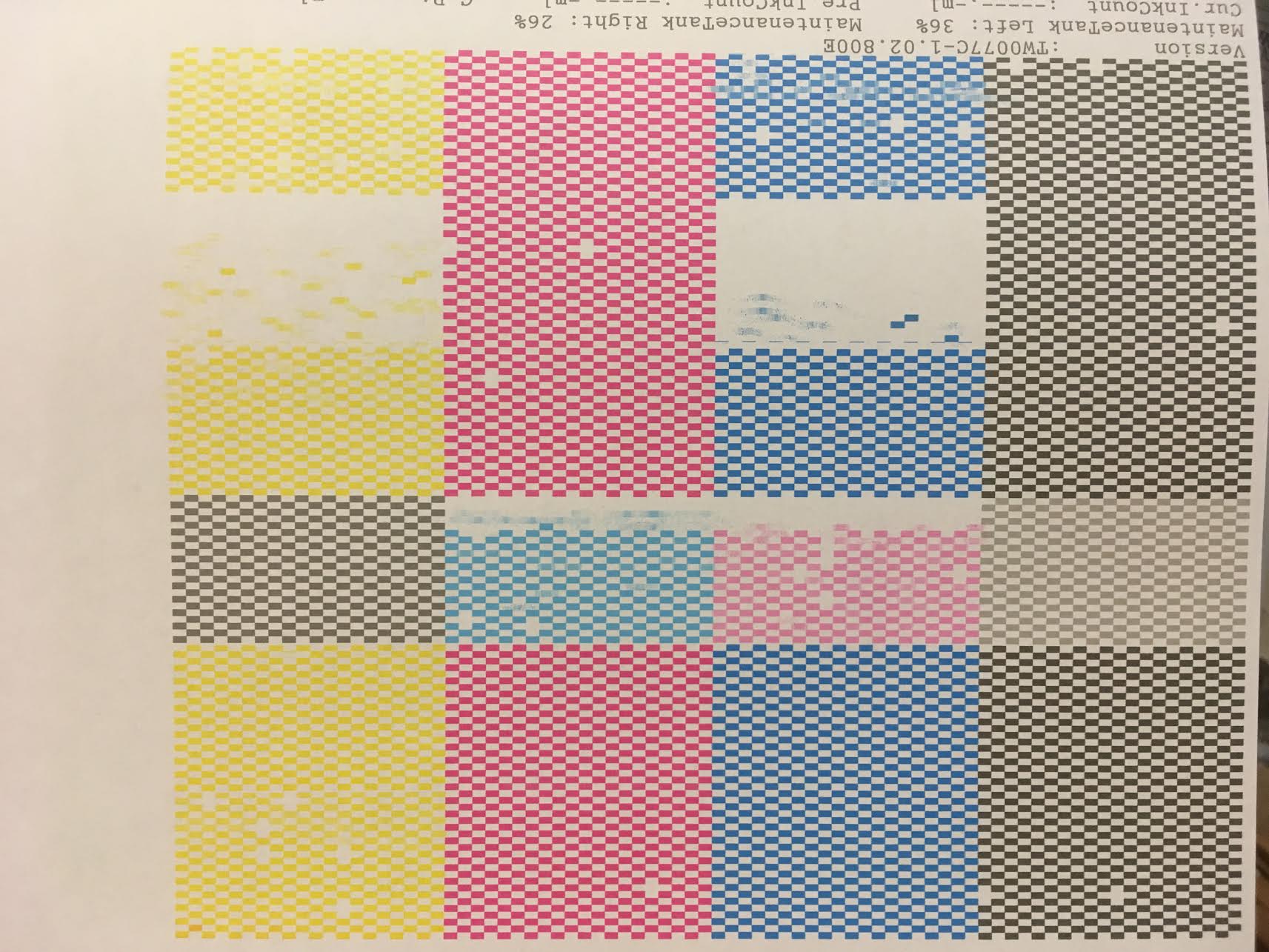

Photo attached showing the problem, and also photo of the nozzle checks, with colours appearing and disappearing…

Thanks!

Time to top off your carts!

The epson carts actually have a “feature” where the chip registers empty when there is about this much ink left in the cart forcing one to throw out that ink. But in this case, refill and re-prime cart and you’ll be good. It’s important to keep the cart full as often as possible for smooth operation.

best,

Walker

Walker,

I guess that once I top off the carts, I should perform a power cleaning to kind of flush away the bubbles that might have filled the tubes from the cart to the head? I guess the problems I am seeing now at the head level come from a multitude of air bubbles that have been getting through the carts, is that right?

Are these carts supposed to allow air to pass through as soon as the ink level goes down? Some of the carts are not that empty, and still show some bubbles at the outlet of the cart (conduct not totally full).

Cheers,

rafael

I think what it really is is the dampers have collected enough air to get spotty. Refill carts, do two normal cleanings and you should be good.

best,

Walker

Walker,

Concerning the advice you made, I would like to ask you something. I might put the 9880 to sleep (I do not intend to print in colour in the next few months) and I was thinking about taking advantage now to insert the piezoflush and fill the machine. Do you think that would be a good idea, now that the nozzle checks are giving problems? I would like to avoid fillling the carts with colour ink, just to take them out for storage… I prefer to leave the colour ink in the bottles for that matter. But I just wonder whether with the piezoflush I will be able to see-verify that I have cleared the problem of air, etc

To fill the 9880 with piezoflush, would you recommend 2 power cleanings, just 1?

How long that piezoflush could stay inside without problems for the head of a 9880?

Thanks and regards,

Rafael

Thanks in advance for the advice,

2 months? Don’t flush. More than 4 months you need to flush.;

best,

Walker

Hi Walker. Not 2 months, a few months! Knowing my agenda, it might very well be a year off for that printer.

In fact, it will be until I need to make a series of colour prints for an exhibition, which might be in a long time, seeing that all my work is lately in B&W. The 9880 was mostly purchased as a backup for the 9900 (that I am using for digital negs with piezo).

So, what do you think concerning my questions with this time frame in mind?

cheers,

r

You need to do an initial fill to get it through on the 9880 (or 4x power cleanings probably).

It can stay for several years that way though 1x cleaning per year is recommended.

best,

Waker