Hi folks. First, I am grateful for the forum and wish I had known earlier what I’ve learned recently! I own a five year old Epson 9900 which had been lightly used during that time, then put in storage for 6 months during a studio move. I now have a persistent clog on the cyan channel. It comes up on the test print in exactly the same place every time I print a nozzle check. All the other channels look perfect.

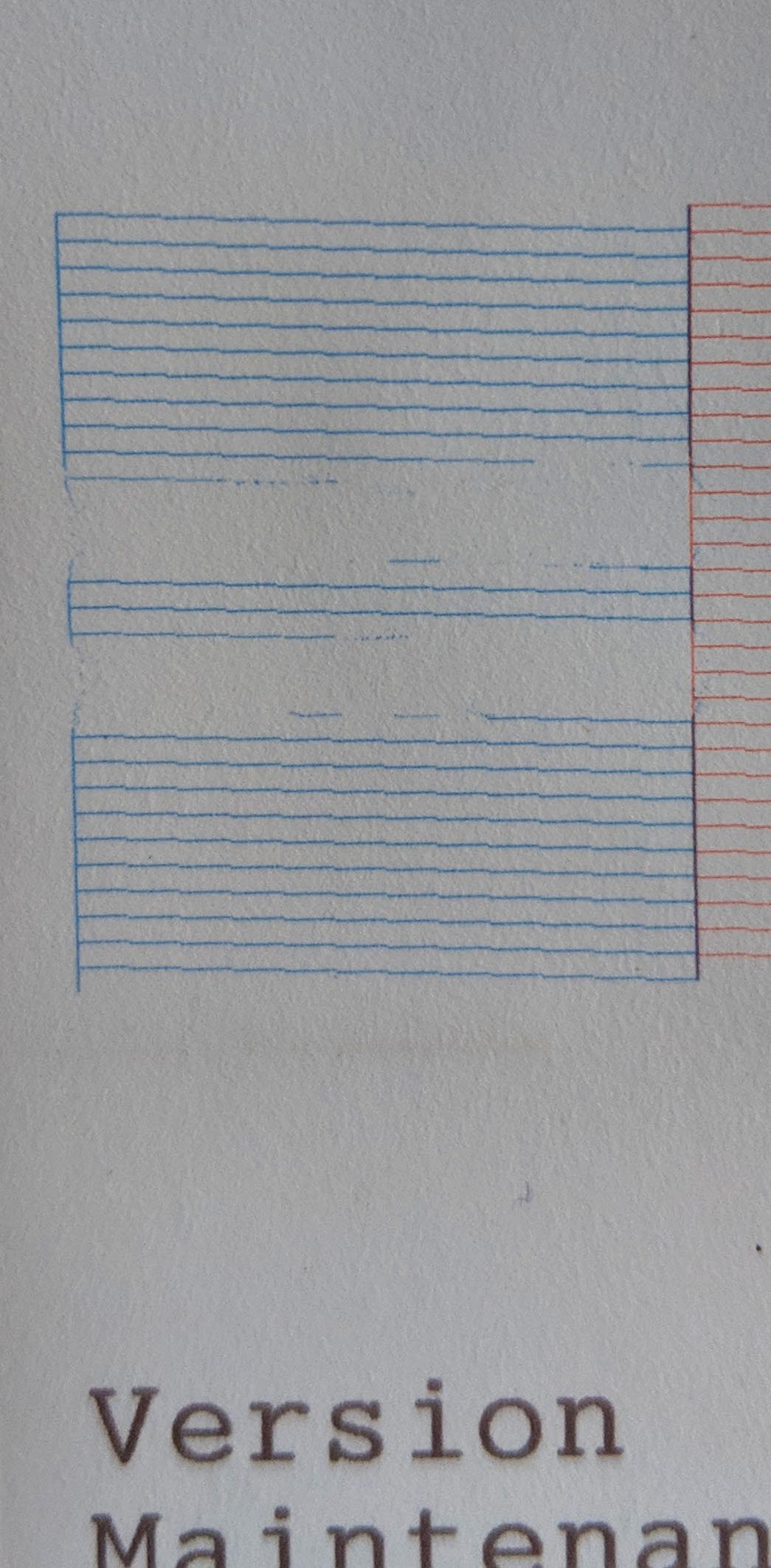

Here’s a shot of the nozzle pattern, taken when there was ink in the system. The pattern with Piezoflush is the same, just harder to see:

I’m writing this to outline what I’ve already done, and to ask if there might be any further step I could take. First I used piezoflush and followed the video instructions to perform the shoe-shine on the head, cleaned the wiper blade and the capping station, and the flushing box. None of these things had ever been done in the five years I’ve owned it, due to my ignorance.

A test print after all this revealed no change in the nozzle gaps on the cyan channel. So I purchased the set of carts and the gallon of PF, filled and primed them, and ran an initial fill. After sitting for a day, I ran a cleaning cycle, but a test print showed no improvement. I ran a second initial fill and let it sit for two more days, then did a cleaning cycle, but still no improvement.

Incidentally, the last cart (the LM channel) might be defective. It reads much lower than the other inks, even though a visual inspection shows the same amount of PF as in all the other channels. Also, there are times the machine does not recognize it - in which case I remove the cart, push on the green end of the chip to nudge it up a bit, and reinsert it. It usually accepts the cart after this.

So back to the real purpose of my note here. Having done all this, is there any further step such as replacing some of the hardware? In one of the posts I read something about Dana’s “nuclear option” but couldn’t learn what that entailed! I am not exactly eager to turn this into a piezography printer, though that could be a last resort.

Thanks for any suggestions - Jim S.