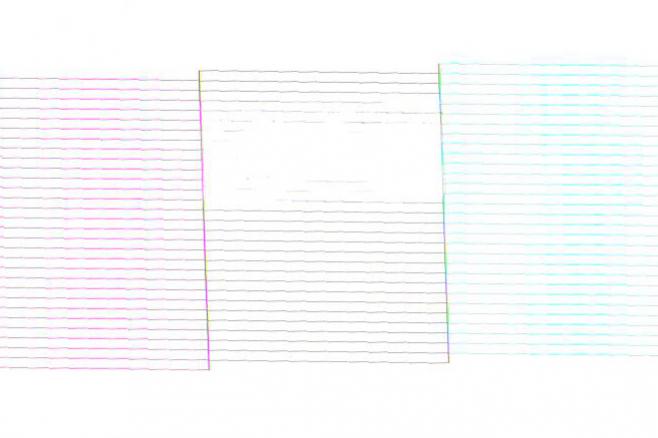

My LK on my 9900 is very consistent with drop outs on the test print. I have attached a scan of the test print.

I have watched and performed the cleaning as demonstrated in the video. I purchased the flush and carts for the MK and the LK. I have run the solution and through the head and let it sit for 24hrs at this point and I did a test print with the flush in it and I can see under magnification that the test pattern is just about the same as it was when this all started. I have performed just about all methods of cleaning that can be performed that I am aware of at this point and not sure what is let to get this LK channel clear.

This pattern has not really changed at all since I first noticed the problem. I have not been able to get any color back in the missing parts of the pattern. I do not know what that means. I know there are differences issues if the pattern changes not sure what it means if they never change.

You have not successfully flushed the head. When you say you’ve “run the solution through the head” please explain. If you had actually done that it would be red instead of Light Black.

What you need to do is upgrade your firmware, boot the printer into maintenance mode, and do a series of strong channel pair cleanings/purges for the channel pair that the LK position is in. This will clear the air block that is in your damper. You will know that it’s getting through the damper if the LK goes red.

However, if the same exact nozzles are still out after actually flushing your head, then you know that those nozzles are shorted.

-Walker

I have run the solution through the head except for where the nozzles are blocked. This is not the nozzle check with dyed flush. It is the same pattern though. When you say strong are you meaning power clean in user mode. While I am on the subject what are the differences in the pairing cleanings in Maint. mode i.e. CL1 CL2 CL3 CL4? If the there was an air block in the damper wouldn’t the pattern change, at least slightly? I have been warned that the SS cleaning, even once could damage the head and create more problems than it solves. Any knowledge of this. The mechanics of the SS process sound pretty harsh. Can you explain why a firmware update is necessary? A lot of questions here but all seem important to be answered if possible.

I have run the solution through the head except for where the nozzles are blocked. This is not the nozzle check with dyed flush. It is the same pattern though. When you say strong are you meaning power clean in user mode. While I am on the subject what are the differences in the pairing cleanings in Maint. mode i.e. CL1 CL2 CL3 CL4? If the there was an air block in the damper wouldn’t the pattern change, at least slightly? I have been warned that the SS cleaning, even once could damage the head and create more problems than it solves. Any knowledge of this. The mechanics of the SS process sound pretty harsh. Can you explain why a firmware update is necessary? A lot of questions here but all seem important to be answered if possible.

Do 2 or 3 CL4s in maintenance mode with Piezoflush in the LK position. Don’t do a SSCL because that will attempt to fire the nozzles at the same time as it vacuums the head and can short the nozzles forever.

Just vacuuming ink/flush through will not damage the head beyond its current state. It can only help.

Because there is a small amount of delayed firing (the small curl of LK going into LC in the vertical) it may be a dead head. This is something that shows up when there is shorted or nearly shorted nozzles. Sometimes it’s just clogged and deflected though so there is a chance . . .

regards,

Walker

I’ve done several CLs at varying levels in maint mode and no change in the nozzle check pattern.

Because there is a small amount of delayed firing (the small curl of LK going into LC in the vertical)

Can you elaborate on this please.

This delayed fire is an indicator of shorted nozzles. (see image of where the delayed fire is happening)

The progression generally goes like this.

- You notice a few nozzles out (usually middle to upper middle of a channel).

- Cleaning it helps but then it comes back pretty quickly.

- A few days of this go by and then you see a delayed firing happen. The whole middle area where the nozzles are getting flaky is actually shifted right a millimeter or so in the nozzle check.

- Then all the nozzles in that area.

- Eventually the whole channel goes.

- It’s attended channel-pair partner goes.

//

regards,

Walker

Yep, that is pretty much the story with me. It is sell or convert. I won’t be buying another Epson. Canon announced a new line of large format printers today it is too bad I need a new printer last week.