Hi Ignotus~

I’m sorry to hear of your continued troubles with this printer after the head was replaced, and that you experienced leaking refill carts. I have been involved in workshops and production printing recently, though Kelly has been helping me with tech support, and I have been trying to keep an eye on things, so I apologize that you did not receive a timely response to your post.

Dampers should ALWAYS be replaced when a print head is replaced, this is standard Epson protocol, so I’m very puzzled why your dampers weren’t replaced, especially considering your printer is 4 yrs old… The fact that you have been running Epson inks since the new head was installed, and are still not having good results, makes me suspect the dampers need to be replaced. I also recommend manual cleaning of internal parts, following our instructions, here: http://www.inkjetmall.com/tech/content.php?133-Printer-Cleaning-and-Preventative-Maintenance

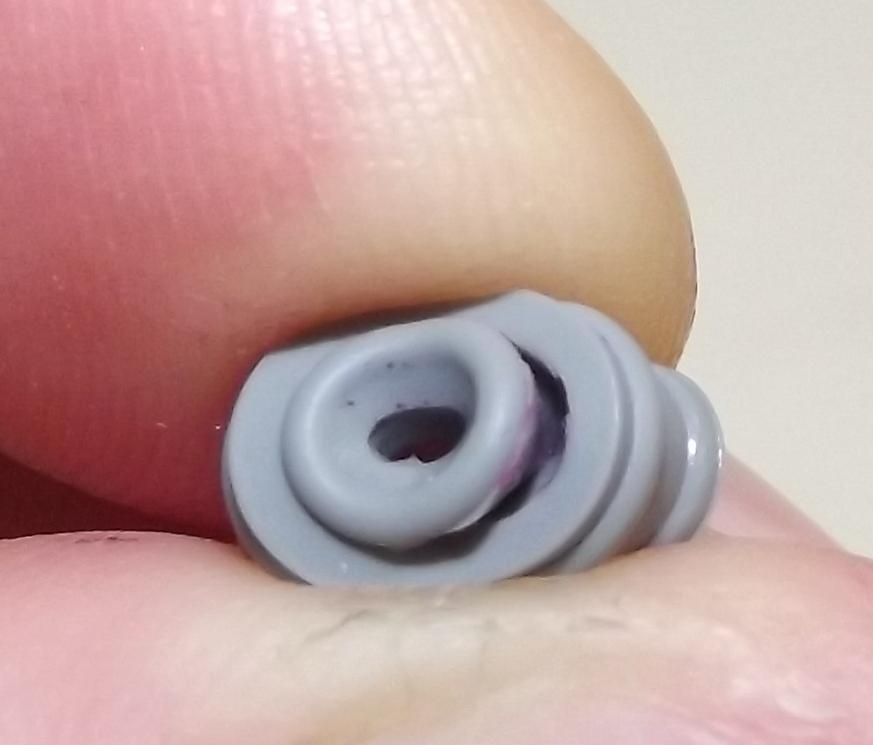

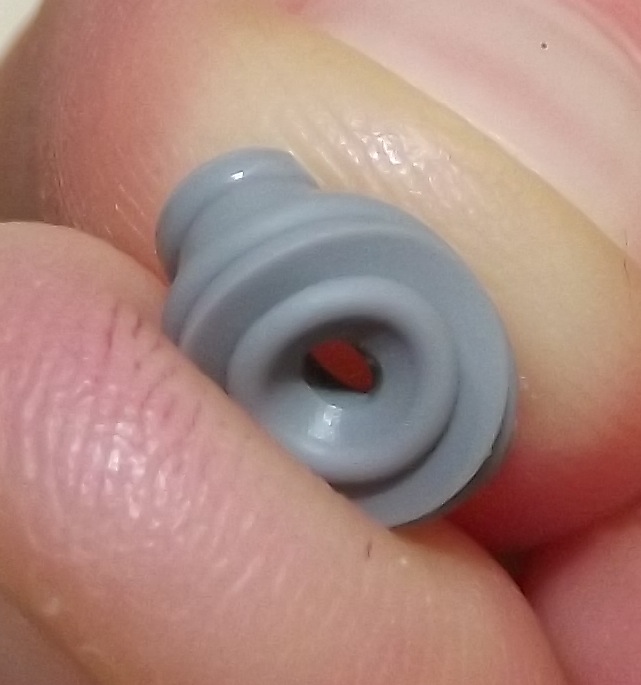

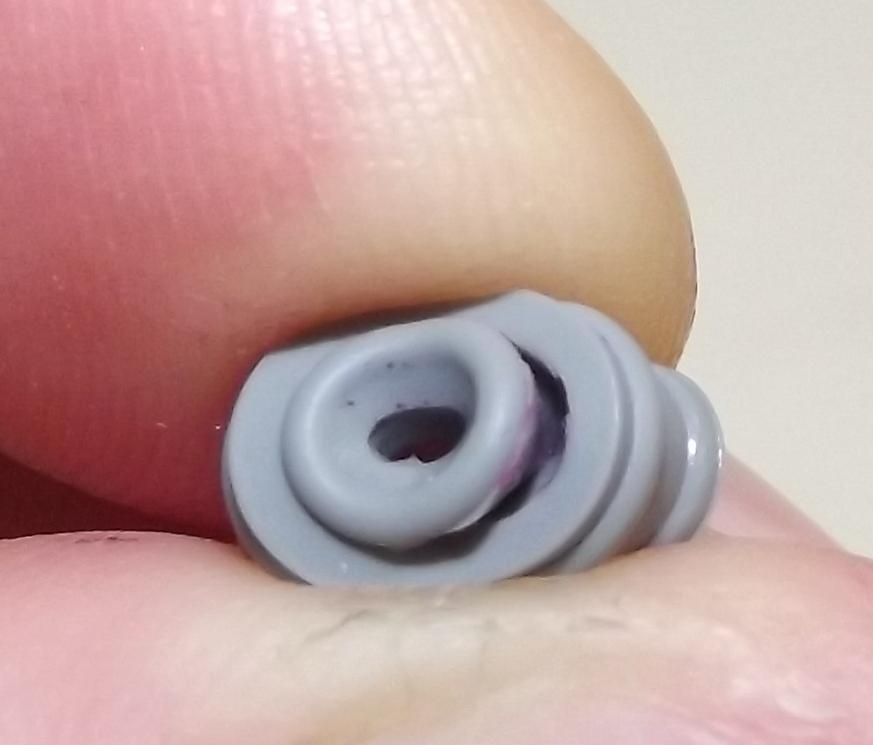

After reviewing your order history, I see you purchased the set of internal bag style refill carts in Feb 2012. If you emptied the ink and refilled carts with PiezoFlush, then three carts leaked from the exit valve while the printer did the Initial Fill Cycle, then I suspect the exit valve seals may have been damaged, which can happen occasionally when priming. The old priming procedure for these carts instructed to insert a slip-tip syringe into the exit valve, then tilting at an angle, and draw up to remove air from the ink bag, and prime the exit channel with ink. This worked well, but we received a few reports of leaking carts, and discovered these customers had accidentally punctured the rubber seal with the syringe, which caused ink to leak out when the printer pressurized carts. The new priming tool and procedure work very well, and we haven’t had a single report of damaged exit valve seals. I attached a photo of a BAD/ripped seal, and good seal for you to see what I’m talking about below.

I will check to see if we have some spare exit valve seals that I can send you to replace with these carts. I will also send you our new priming tool, which is a small syringe with plastic priming tip, which opens the exit valve to prime, without damaging the rubber seal.

To replace the rubber exit valve seal:

Hold the cartridge exit valve up and carefully slide the plastic tab off the exit valve to remove the rubber seal. You would want to be very careful when doing this with a cartridge that contains ink to avoid accidental spilling- make sure the cartridge remains up and take care when handling the exit valve parts as they are small and I have certainly shot the parts across the room by not holding them in place when I slid the top plastic door off (due to the spring pushing up). To avoid shooting parts across the room, hold your finder over the exit valve when sliding off the plastic piece, then using a straightened paperclip, insert the paperclip tip straight thru the gray rubber seal center hole and gently pry up to remove it- behind the gray rubber seal is a tiny metal ball and spring. To put it back together, put the spring in first with metal ball on top, then push the gray rubber seal straight into the hole and while holding the rubber seal down, slide the plastic piece back in place- making sure the rubber seal is flat and evenly secured under the plastic cover.

I hope this helps. Please let me know what you discover, if you have questions or there’s anything else I can help you with. I will be out of the office tomorrow, but have left myself a note to check for replacement exit valve seals on Thursday morning when I return, and will let you know if I locate some to send you.

Best regards~ Dana