Hello,

I’m posting on my personal account for Latitude Chicago, as we’re in the process of getting activated to post.

On Saturday a client was printing some 24x36ish mural prints. She notified me after two prints had gone visibly lighter.

[ul]

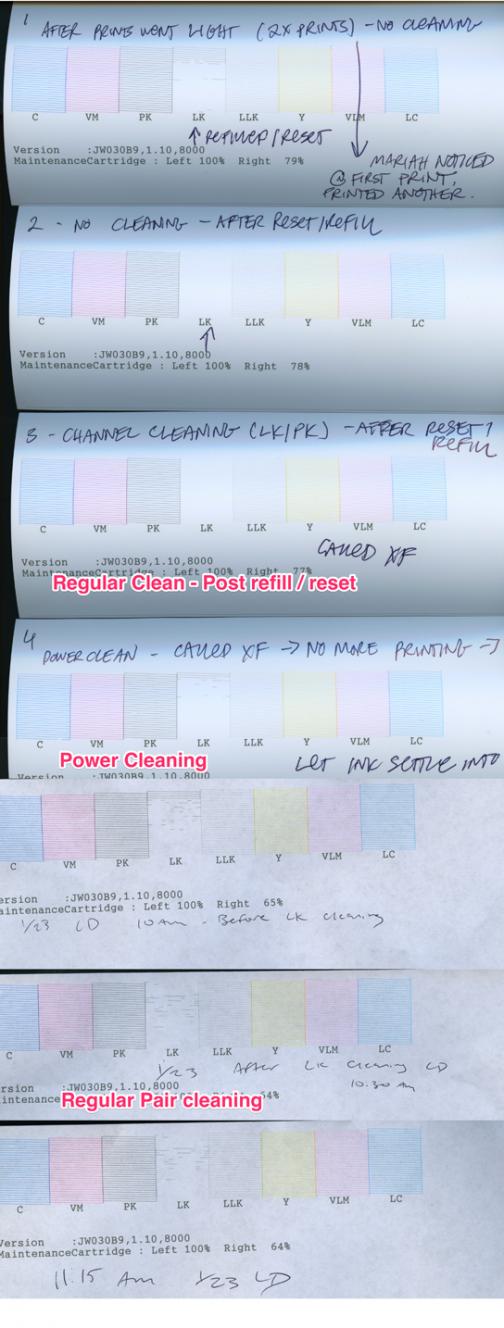

[li]I suspected a cart had gone dry so did a nozzle check. Half of the pattern was gone on the LK nozzle, and the cart itself was really dry (the cart is an older refillable IJM cart with a bladder in it).

[/li][li]Refilled the cart and reset the chip.

[/li][li]Printed a nozzle check. LK channel gone.

[/li][li]Did a regular cleaning + printed nozzle check. LK still gone.

[/li][li]Called Lab Manager and explained chain of events. He advised a power cleaning. Did power cleaning.

[/li][li]Nozzle check revealed a few nozzles on top were returned.

[/li][li]Called Lab Manager again. He advised letting printer sit so that ink settles into line and head.

[/li][li]Printer sat for a day and a half until Monday AM.

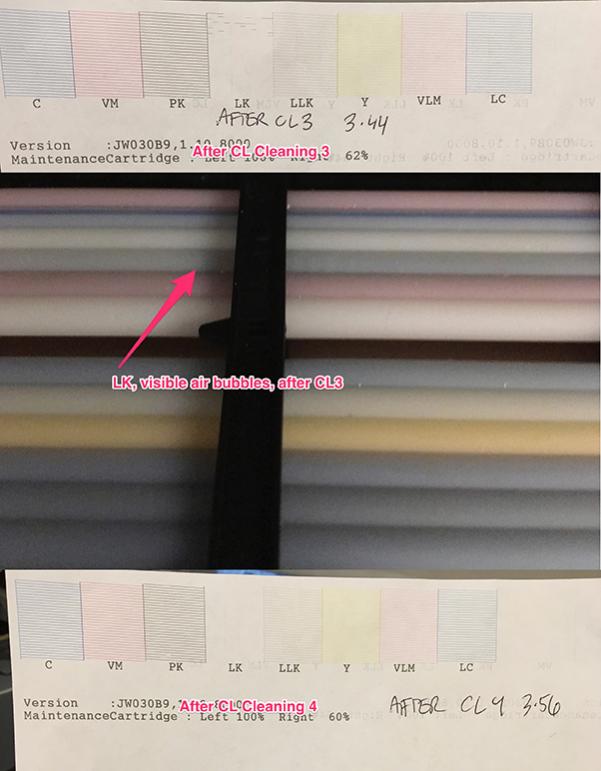

[/li][li]Monday AM nozzle checks + one cleaning attached.

[/li][/ul]

Any course of action worth trying? Initial Fill?

Incidentally, saw this post from Walker on Epson Wide Format group this morning, would any of this apply to us or is it too late?

[I]When nozzles start failing after a nozzle clean it could mean a few things. Here’s the rough sequence in order for check.

- Cruddy cleaning assembly (flushing box, capping) that is letting air stream across the head during the vacuum. (most often seen as a full channel drop after cleaning in the x900s).

- Dirty wiper that is actually plugging the nozzles after a clean. (random nozzles clogging after a clean)

- Crud is is straight-up dried onto the head (usually not a factor).

- Dampers screen are full of crap (happens w/ OEM and non-OEM).

- Head Manifold is full of crap.

- Piezo actuators are plugged (semi permanent nozzle death where you see 1/2 deflected fire of a nozzle every once and awhile).

- Piezos are burned out or TFT film is separated (permanent nozzle death usually starting in the middle of the print-head and working it’s way outwards accosted with a delayed fired at the very beginning pre-burnout.)[/I]

Annotated image attached in-line below.

Thanks for any advice and help!

Andrew @ LATITUDE | Chicago