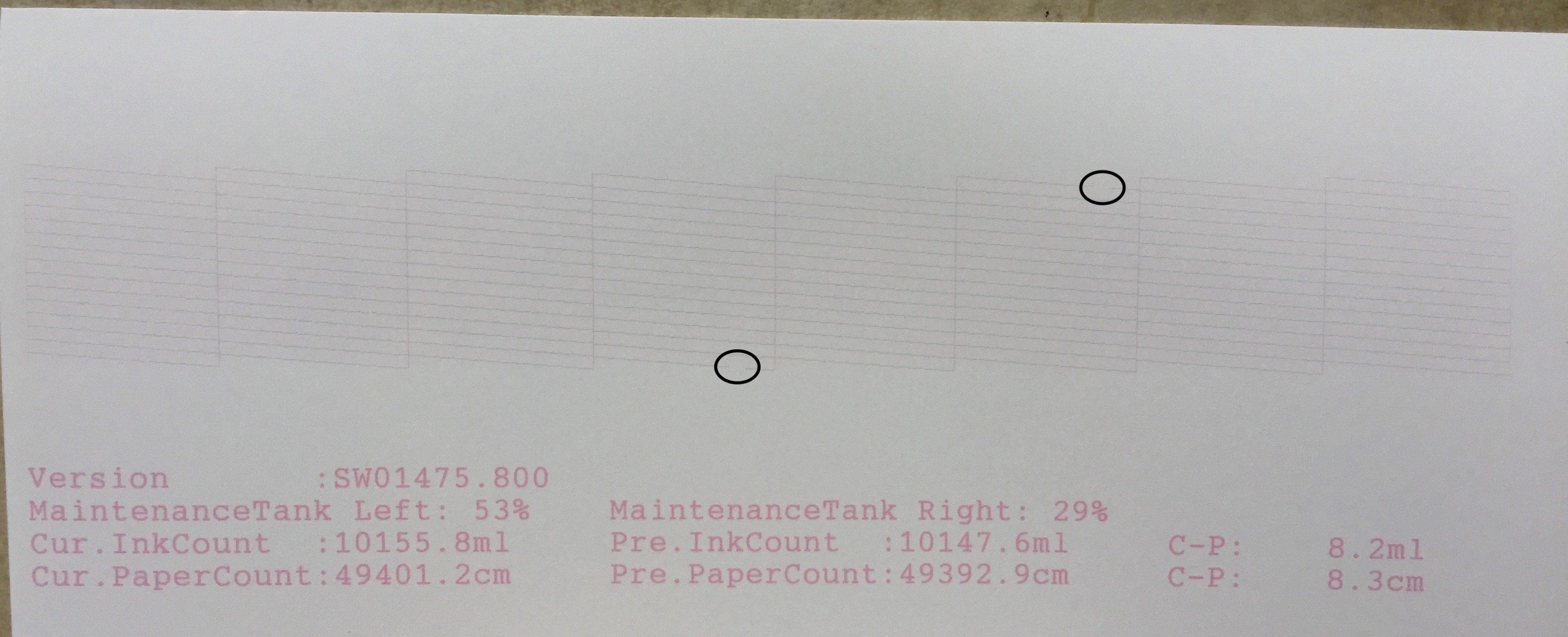

I’ve got a 9800 I use for purely black and white printing with all black inks that has two clogged nozzles I’m trying to clear up. See the attached image; it’s channels Y and LC that have the clogs.

So far I’ve done two INIT-FILLs with Piezoflush, and “shoe-shine” cleaned the head twice. There’s still gunk coming off the head so maybe that’s still not clean enough.

The dampers are relatively new along with the wiper and capping station.

I was using some of the older bag-style carts with Piezoflush that seem to be a bit leaky to try and clean this and yesterday received a new set of new-style carts to replace them. I plan on filling those and doing another INIT FILL cycle to see if that loosens the clogs. Maybe there’s a problem with the older carts having enough pressure to dislodge the clogs.

Anyone have hints on what else I should be doing? At what point do I say screw it and give up?

If I give up can those channels be used for anything? Or are they pretty much toast with the single nozzle out on each?