Cleaned wiper blade, capping station, and flush box with Piezoflush with bounty paper towels and foam swabs. Also cleaned the bottom of the print head with piezoflush “shoe shone” style with Aztek wipes. I replaced all 8 dampers, o-rings, and joint screws. No leaks observed where tubes mount to dampers. Ran two power cleans and several nozzle checks (with cleaning) – 90 minutes apart. Cleaned wipe blade, capping station, flush box, and print head bottom a 2nd time.

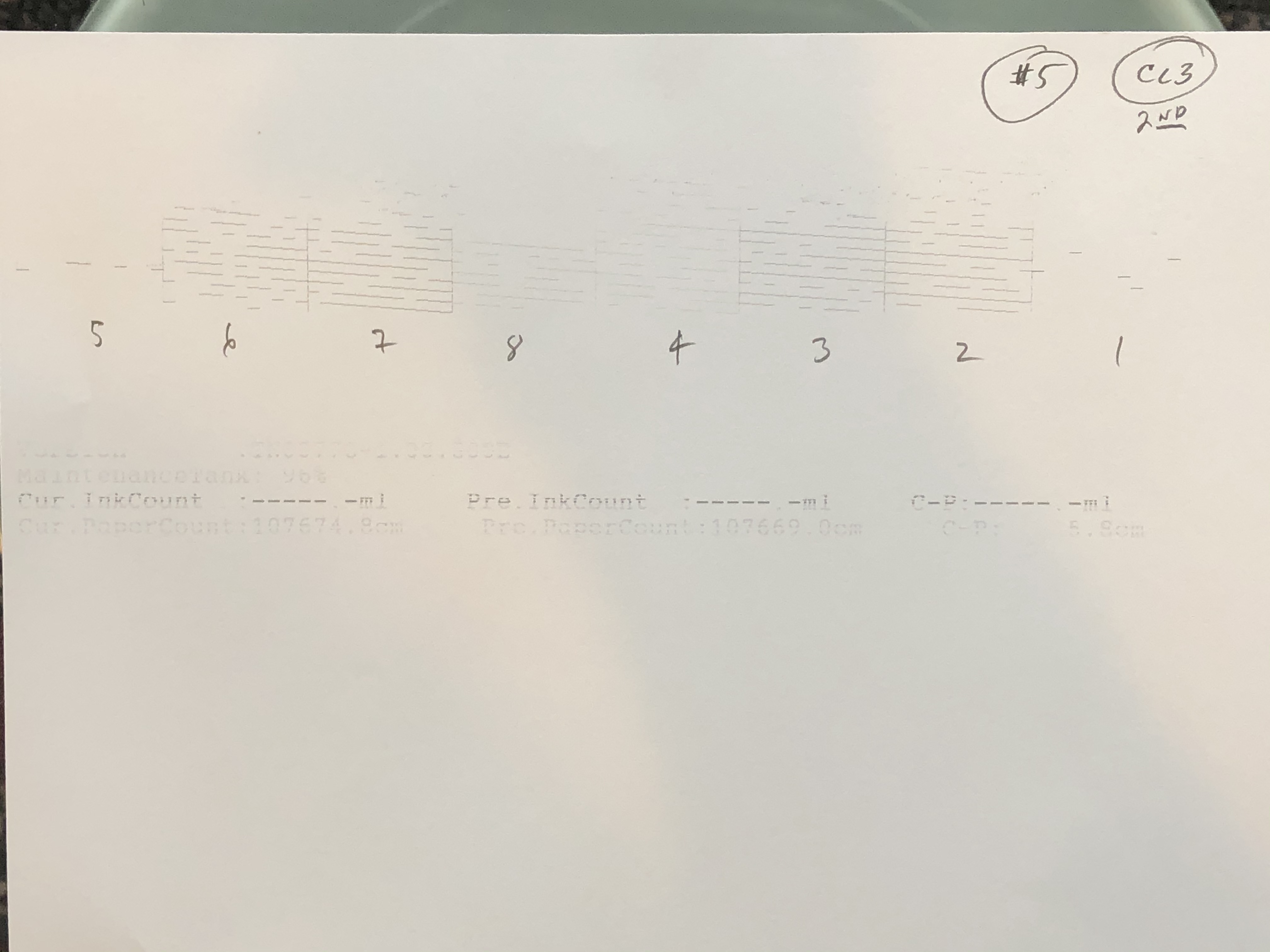

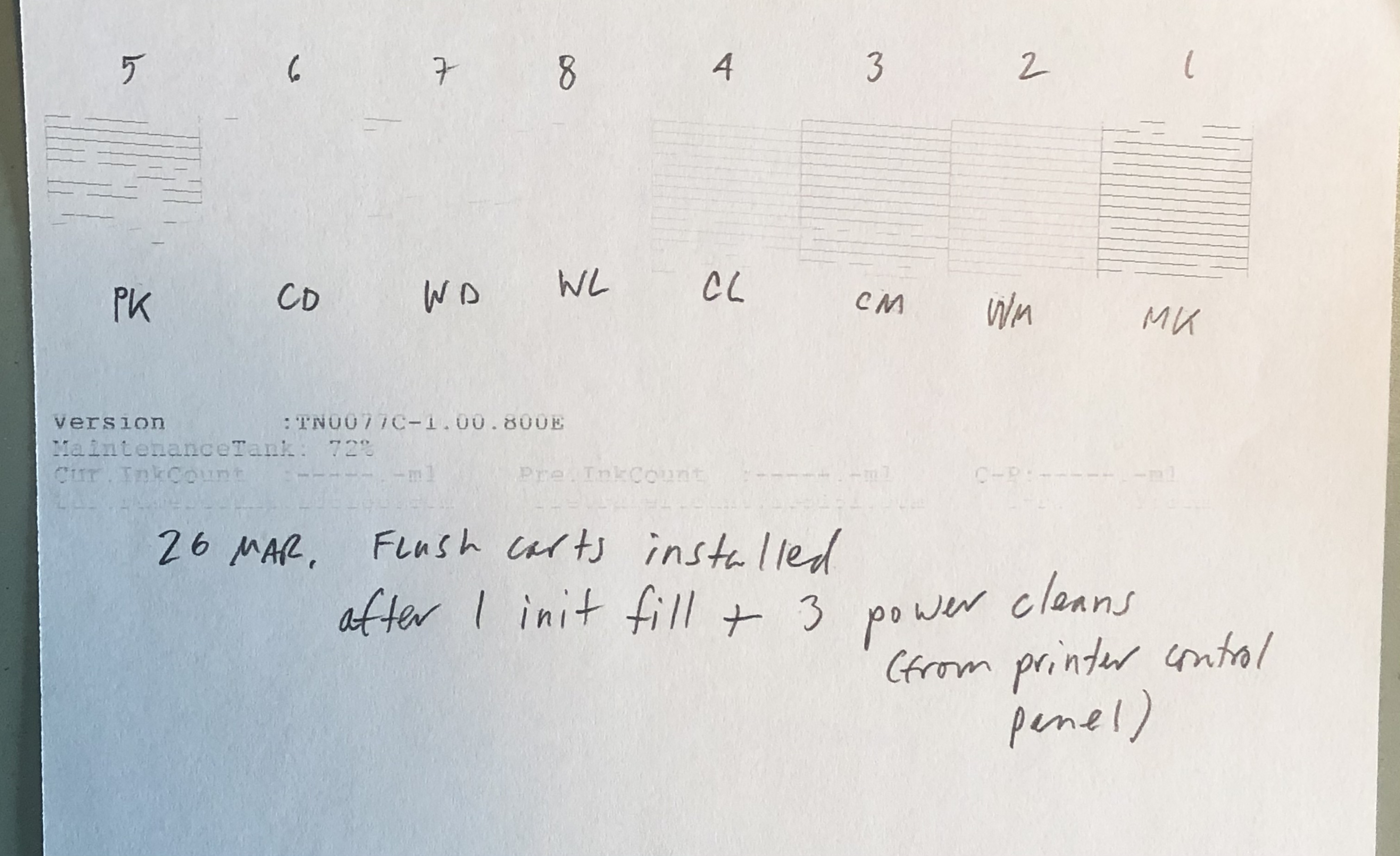

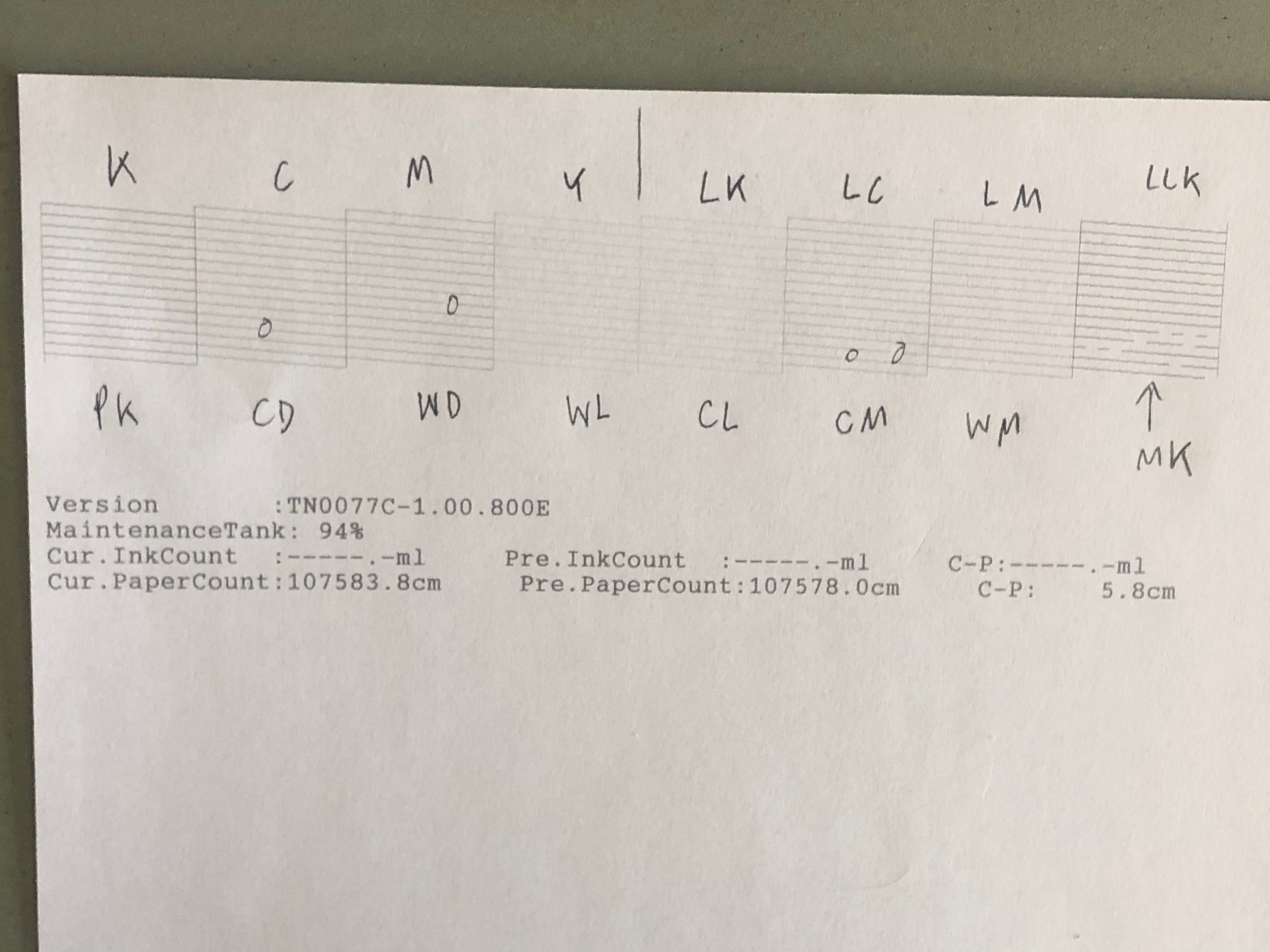

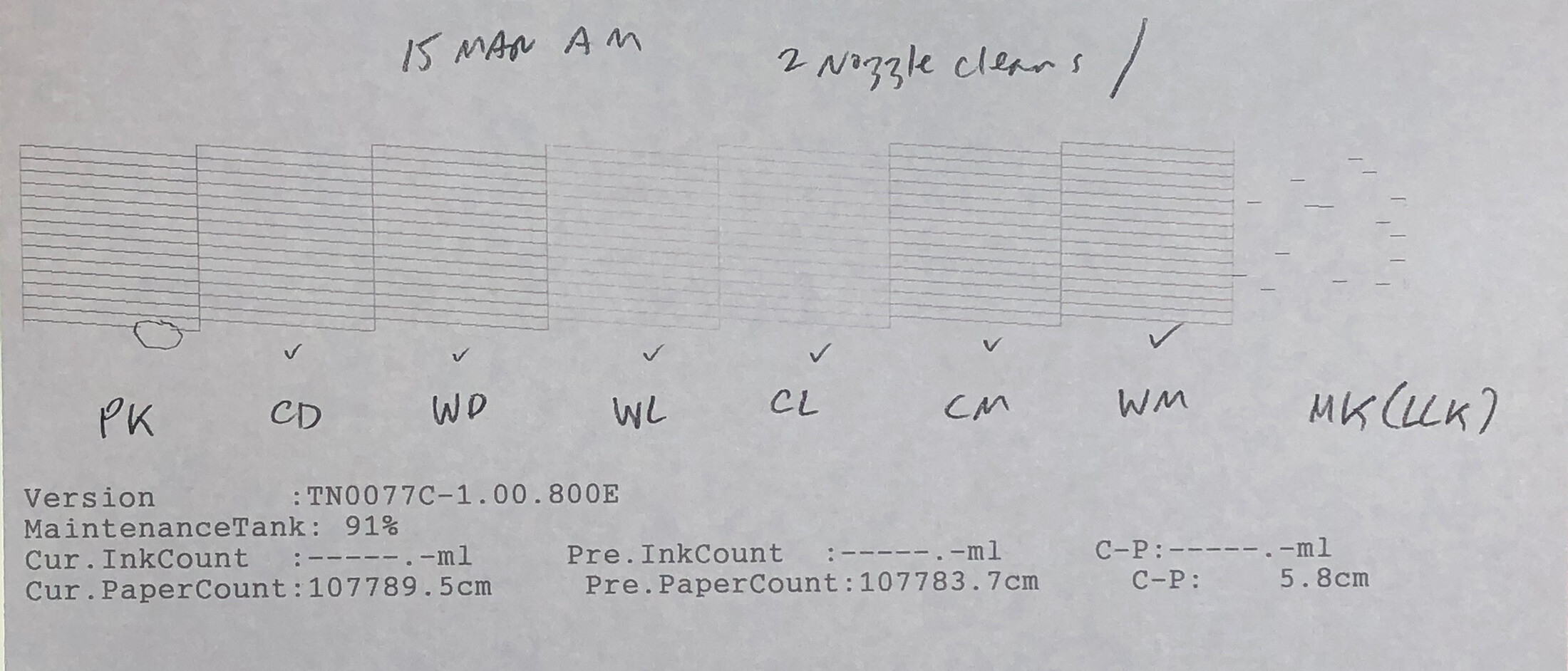

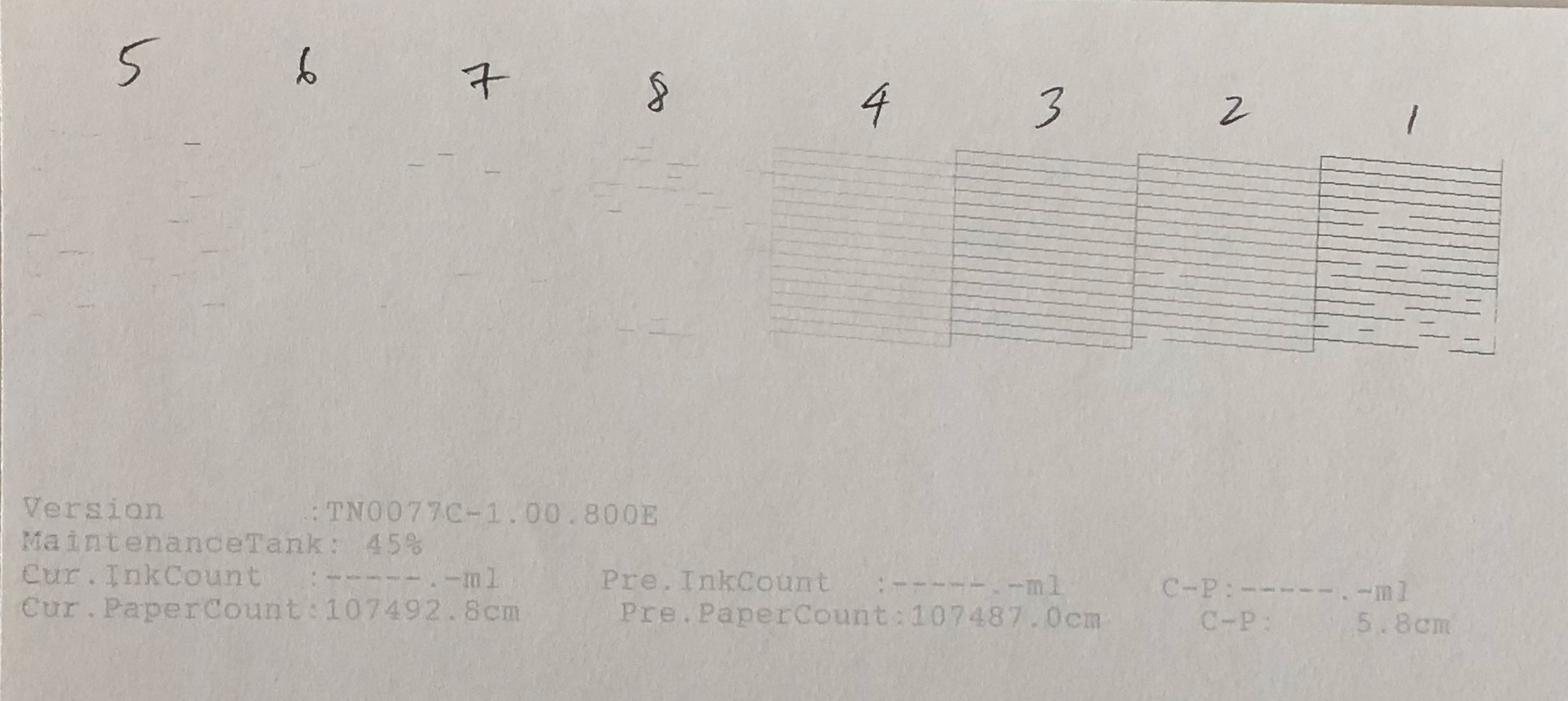

Here is a photo of the nozzle check. As you can see the right side, carts 5, 6, 7, and 8 have almost no ink; whereas carts 1 - 4 are almost there (note I have HD-PK installed in slot 1 – remapped).

Any ideas would be appreciated!

Here is an update…

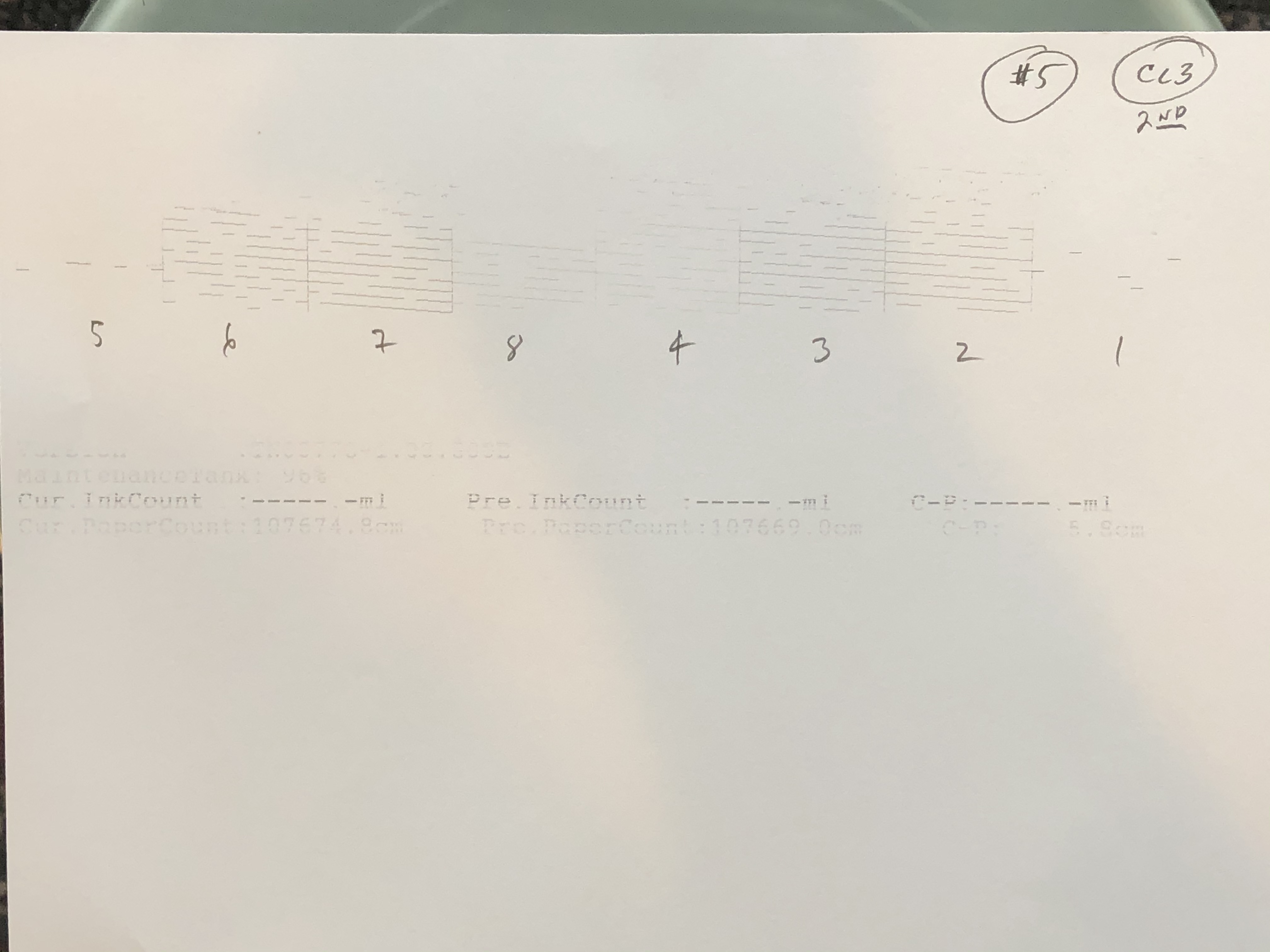

I ran an init fill cycle. Loosened positions 5, 6, 7, and 8 (which on the 7880 are the right side carts). After running about 6 nozzle checks and associated cleaning cycles here is the latest nozzle check. Between nozzle checks where there was a gap in the pattern I went in and very slightly loosened the ink line. There are no leaks.

MK (remapped to the LLK slot) seems to be getting worse. The other channels shown go in an out of a good nozzle check (meaning a previous nozzle check was perfect and the next one shows a gap are one or two locations).

Any suggestions on next steps would be appreciate.

thanks.

Michael

me-thinks you still have suction issues between the capping station and the pump and the waste box . . . there’s probably gunk there and it’s not able to suck that well causing deflections after a clean. and also the wiper blade rubber is possible fraying. These degrade.

-W

Thanks Walker. Capping station and wiper blades are still available so that order has been placed. I’ve checked the usual places (SDott, etc.) and they do not have a flushing box. Any leads on where I could find one? Do you think the flushing box could also be contributing to the clogs?

Hi Michael,

Got your email, but then I saw this so I’m responding here.

I think that the flushing box, being downstream of the head, is unlikely to be directly contributing to the clogs, however, I have heard (probably on the Epson Large Format forum) of folks removing, cleaning, and reinstalling it. The piece is little more than a funnel that drains through a tube to the maintenance tank. If my memory if functioning, I recall that the hose can get gunked up to the point of blockage. Might be worth doing as a precaution even if it’s not the cause of your trouble.

By capping station, do you mean the Pump Cap Assembly like this one at SDott?

I had to do all this on a 7600 years ago. It got me a couple or 3 more years of use from it before the head sprung a leak.

Keith

Keith,

Thanks. I ordered the pad and the rubber wiper (actually two of each), not the entire assembly. SDott delivery was very fast for the dampers so I expect them by midweek. I also found the flushing box from a U.K. company so I ordered two of those as well. I will pull the flushing box and inspect it. I’m also going to pull the right side of the printer housing to get ready for the new parts. Phew, I’m exhausted already,  !

!

March 14th update. I installed a new wiper, capping station (the pad), and flushing box. I applied a little warm distilled water to the flushing box and capping station. I noted that there was water/ink on the maintenance tank (I installed new pads in the maintenance tank to make troubleshooting easier). I double checked the capping station to insure there was no cover or cap on it. I noted on the capping station that there were rings of water/residual ink located above where the three tubes (one on top and two on the bottom) exit the back of the capping station. I also did the “shoe shine” with distilled water on the bottom of the print head and it was basically clean (I did this extensively with piezoflush after I changed the dampers so I didn’t expect the print head to be very dirty).

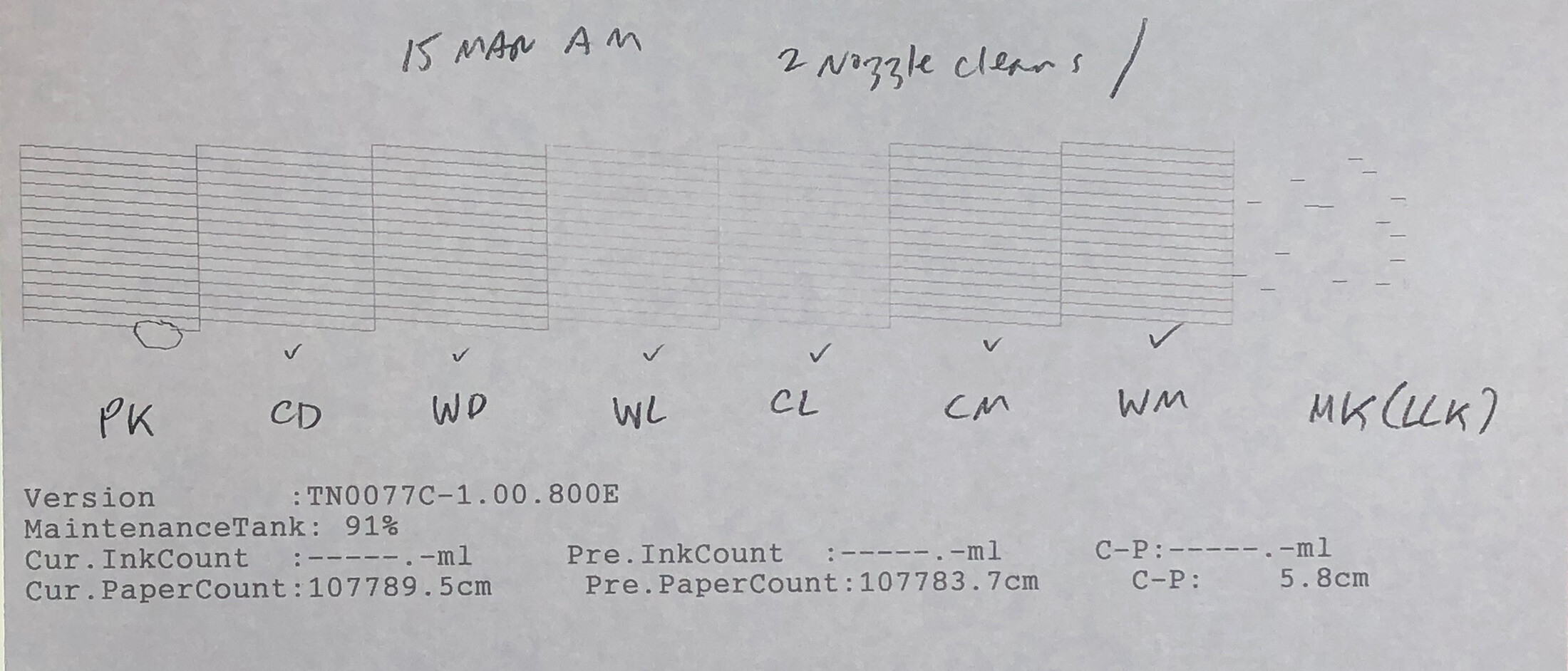

I ran a nozzle check and one nozzle clean: nothing printed. I then ran two CL2 and two CL3 cleanings (each time running a nozzle check after the clean). Each time I ran a nozzle check I started to see a little more of the nozzles coming back (they are a long ways to go still).

Here is a photo of the nozzle check after one nozzle clean, two CL2 and two CL3 cleaning cycles:

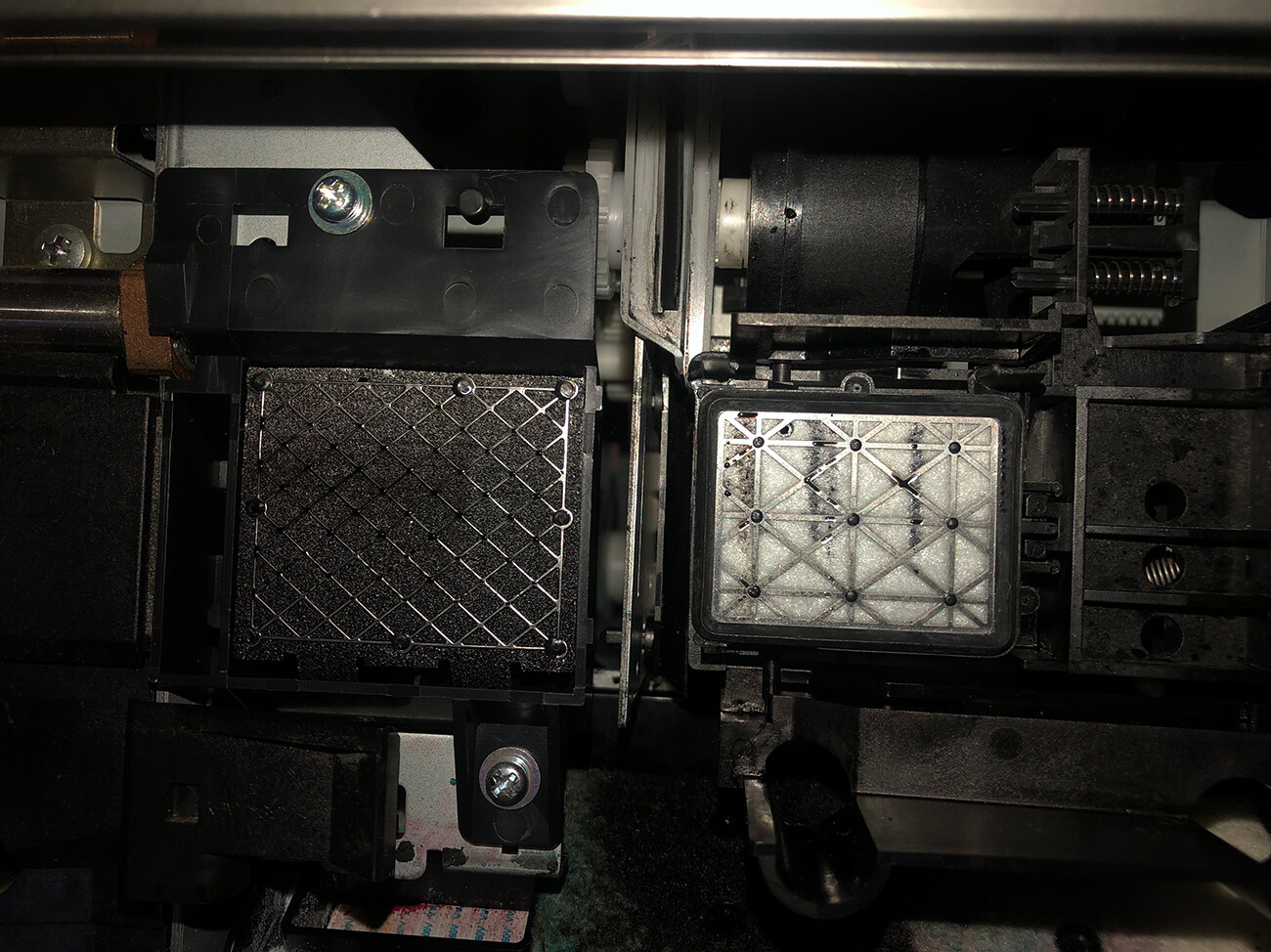

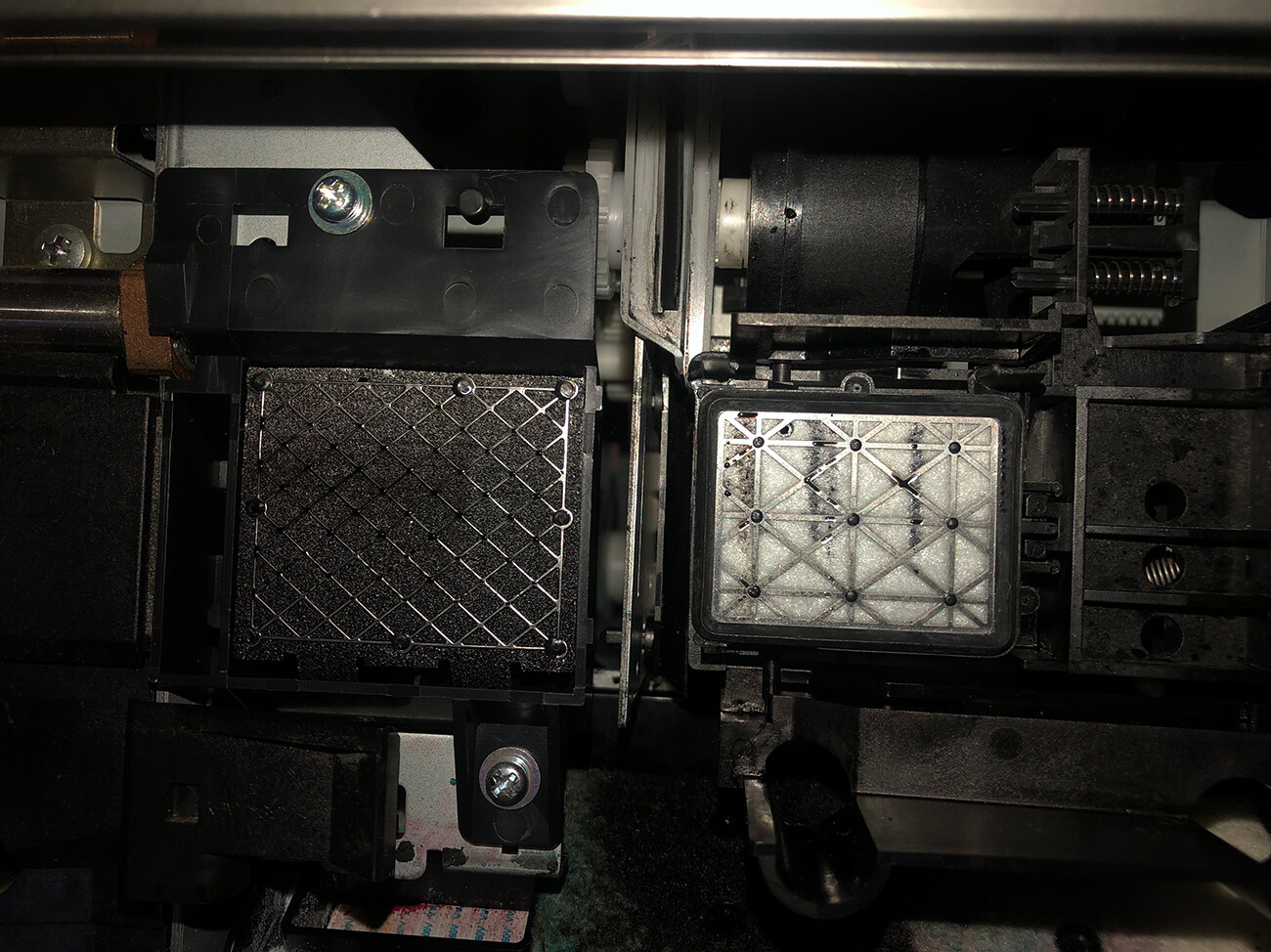

Here is a photo of the capping station / flushing box area after the five cleanings.

Note that the capping station has three vertical stripes with a little bit of ink residue. Does this indicate the capping station is working? Is this indicating those three positions are starting to work but the others have not? Do I need to run a stronger cleaning cycle? Any other suggestions?

thanks,

Michael

March 14, afternoon update… well, the nozzle check is getting better (this after allowing the printer to rest for a few hours and then running 2 nozzle cleans and3 CL3 cleans).

MK (remapped LLK) has not improved at all.

And I am still seeing the vertical “banding” on the capping station as shown above.

Thoughts?

Thanks.

Michael

The cap station which is also what is pulling ink from the head I believe should be FULL of ink . . .

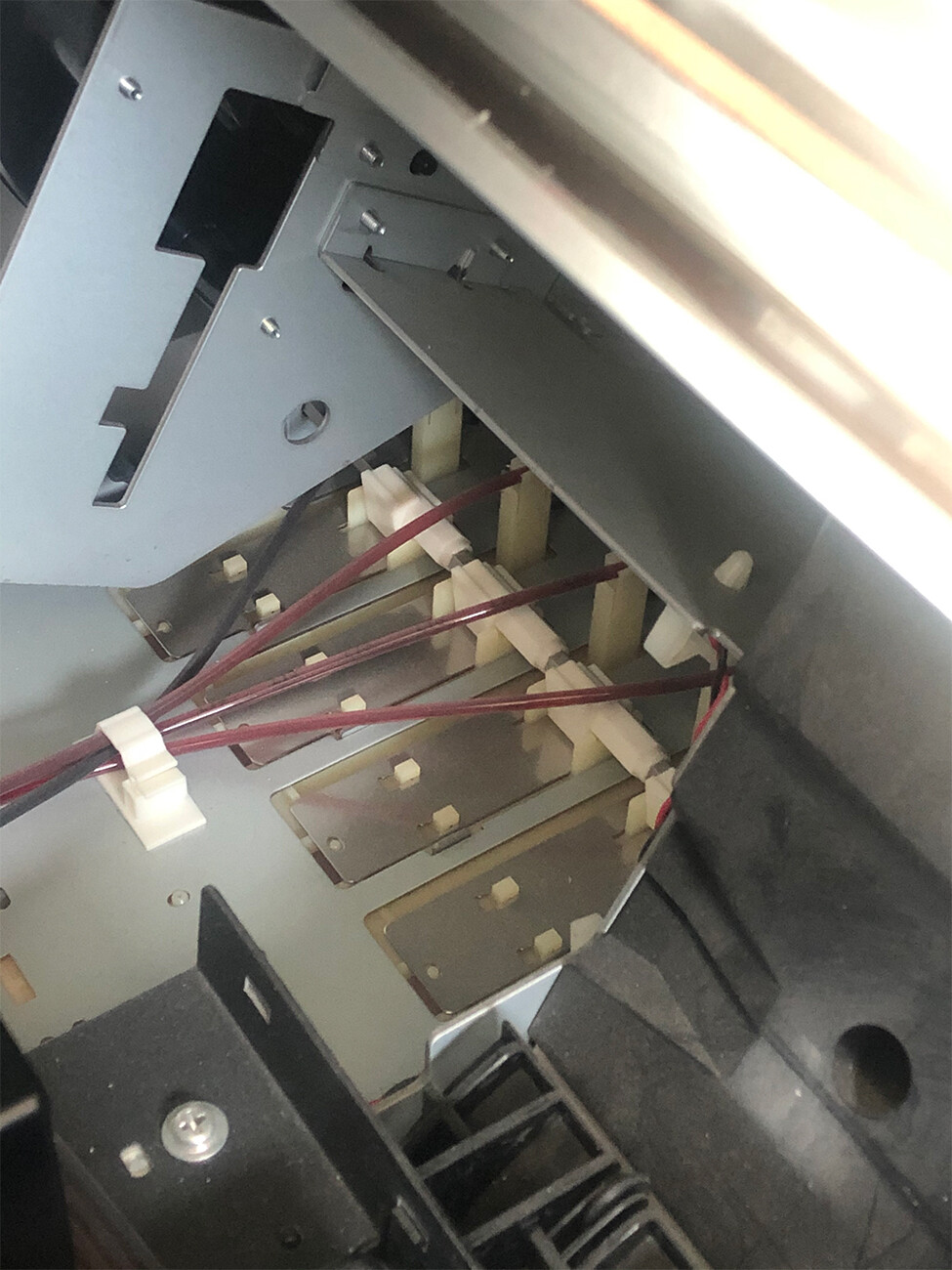

something is miss-aligned and really no ink is flowing. Take right side off and look at the ink tubes when running a cleaning. You should see ink flow.

-Walker

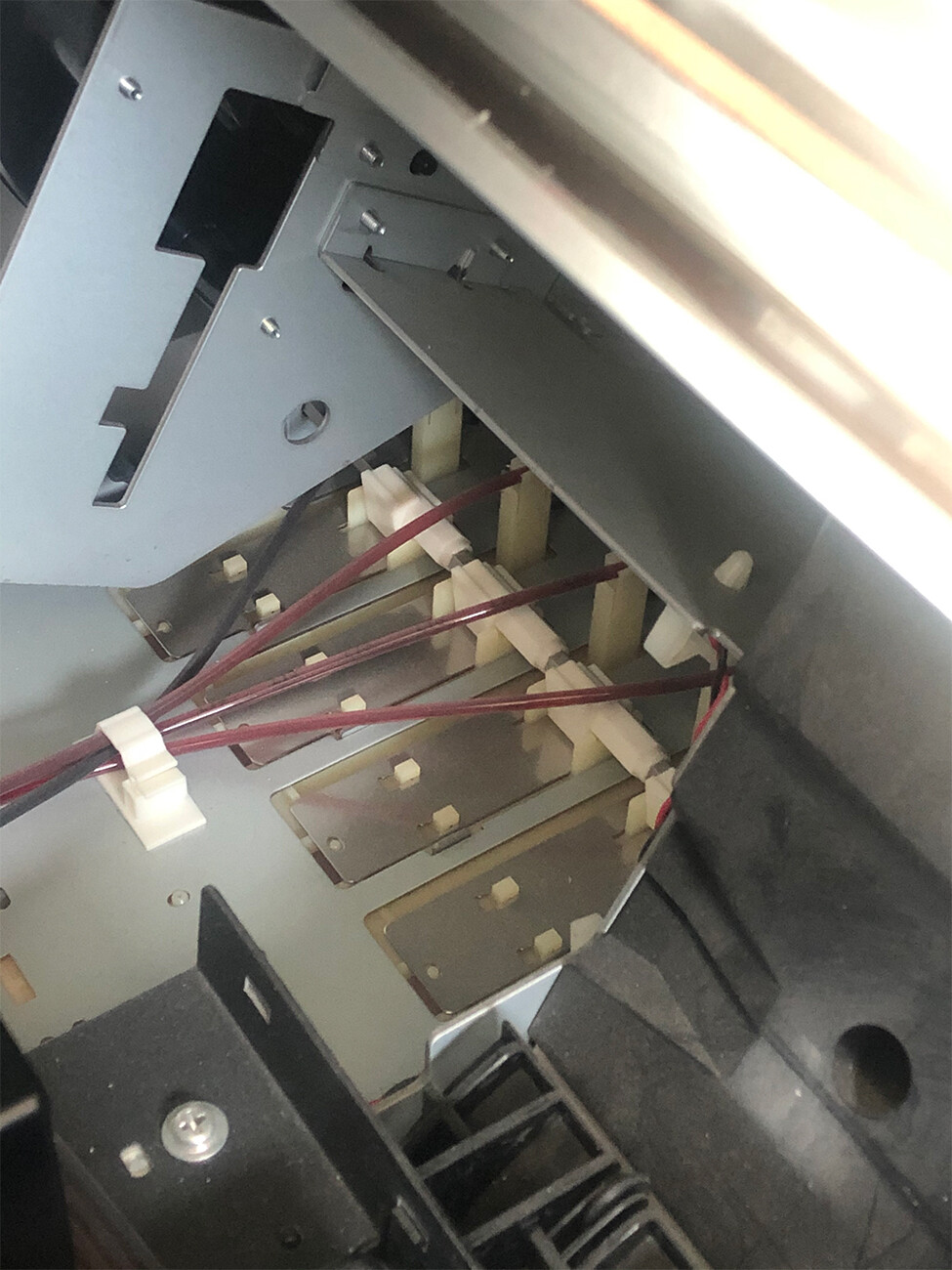

Took the side cover off. ran two nozzle cleans from the printer utility and then ran a nozzle check.

I did not see any ink coming through the two tubes as shown in the photo. I checked that the two black ink tubes were not crinked between the back of the cap station and the bottom of the pump. And when I installed the new cap station I removed both black tubes and insured they were not blocked. I did not completely remove the black tube that connects to the top of the cap station.

During the cleaning process I noted that all gears were turning, the wiper blade went up and down, and the pump was spinning.

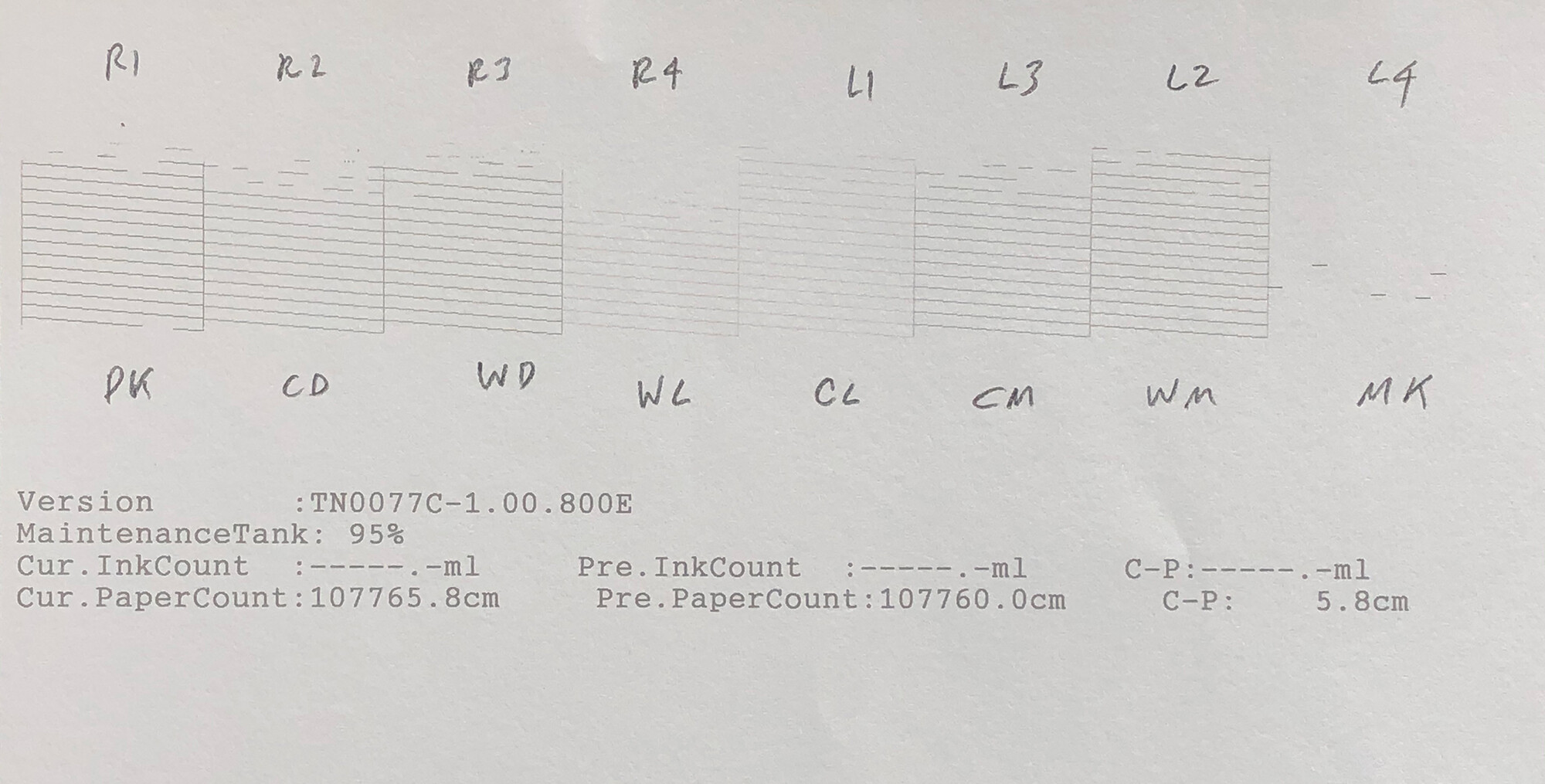

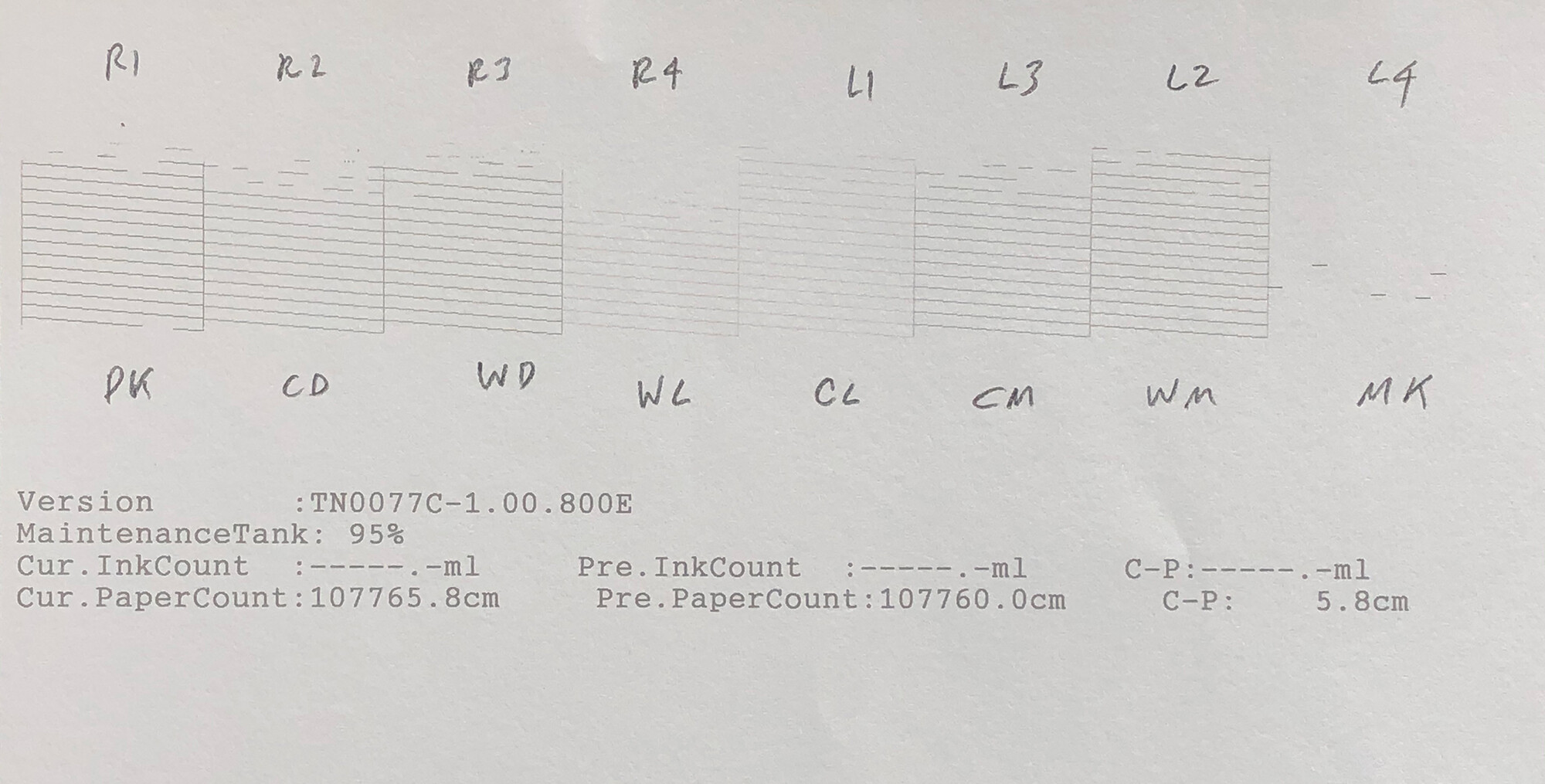

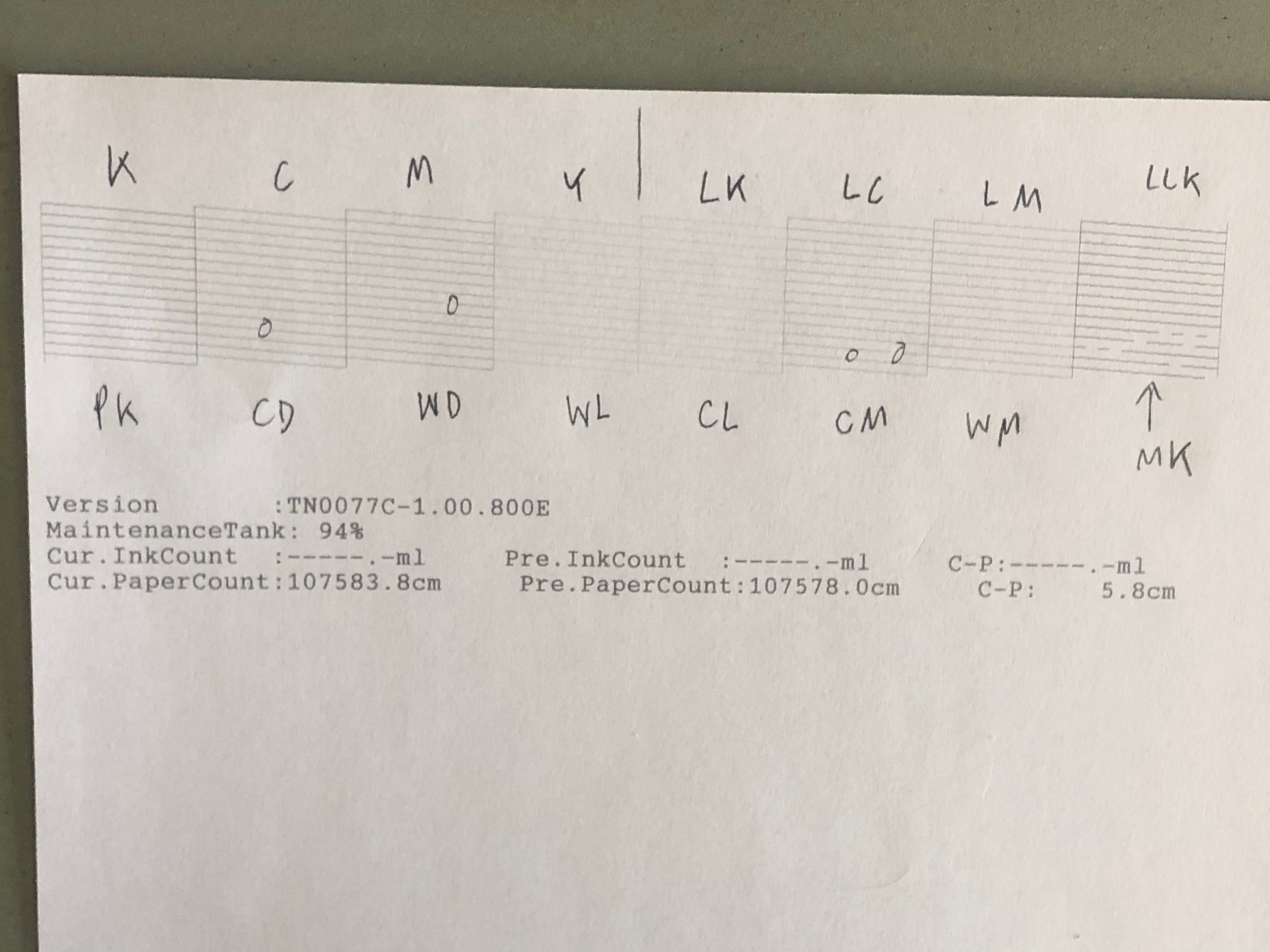

Here is the nozzle check. This is the best it has been since replacing all the parts on Saturday. Note that MK (LLK position) still is miserably “clogged”. PK has two “segments” missing, and the remaining 6 positions are good.

I see your point and agree based upon previous workings that the cap station should be completely covered in ink.

Is it possible that when I reattached the two black tubes to the bottom of the pressure pump that I inserted them too far? Is that even possible?

Do you think I have a bad pressure pump on the cleaning assembly (complete cleaning assembly’s are still available)?

And any thoughts on the MK (LLK) channel?

thank you!

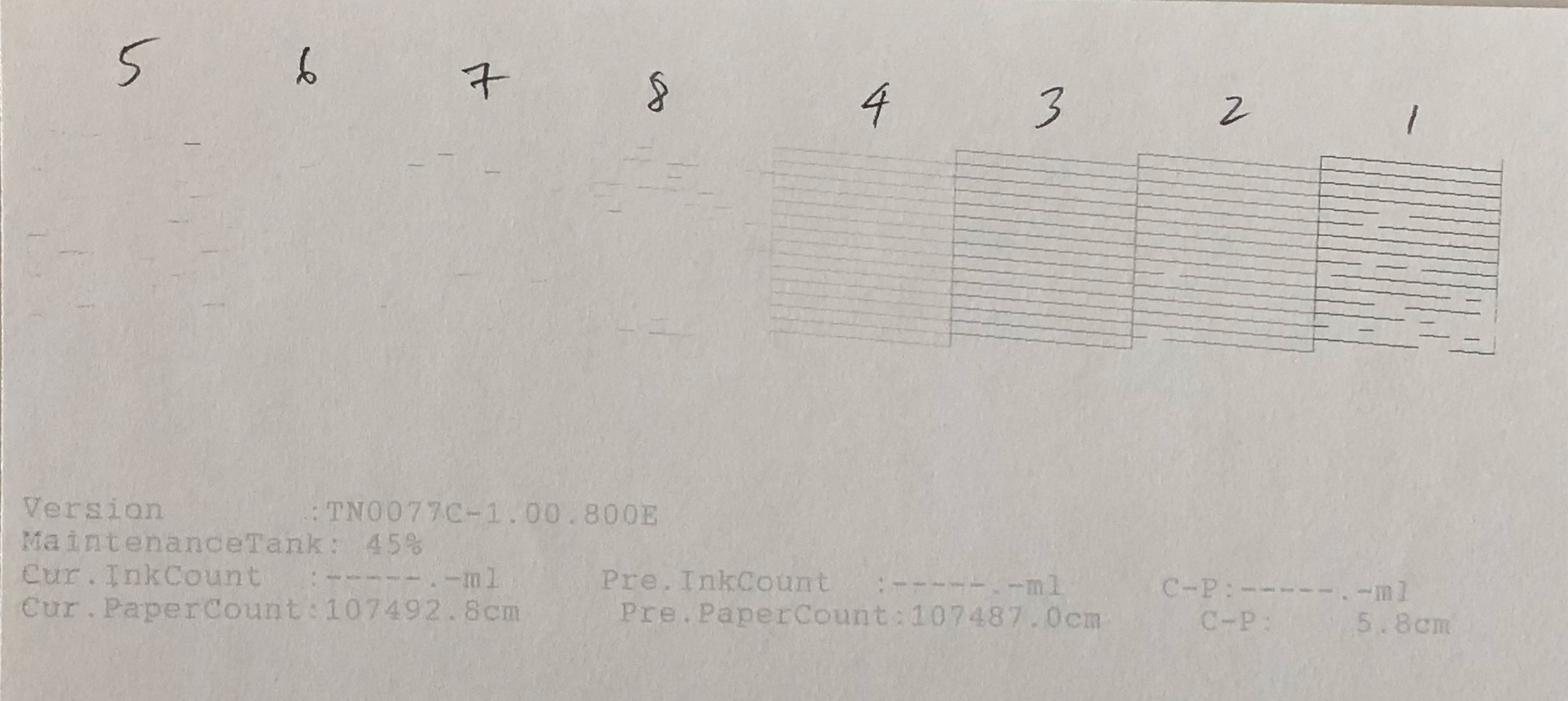

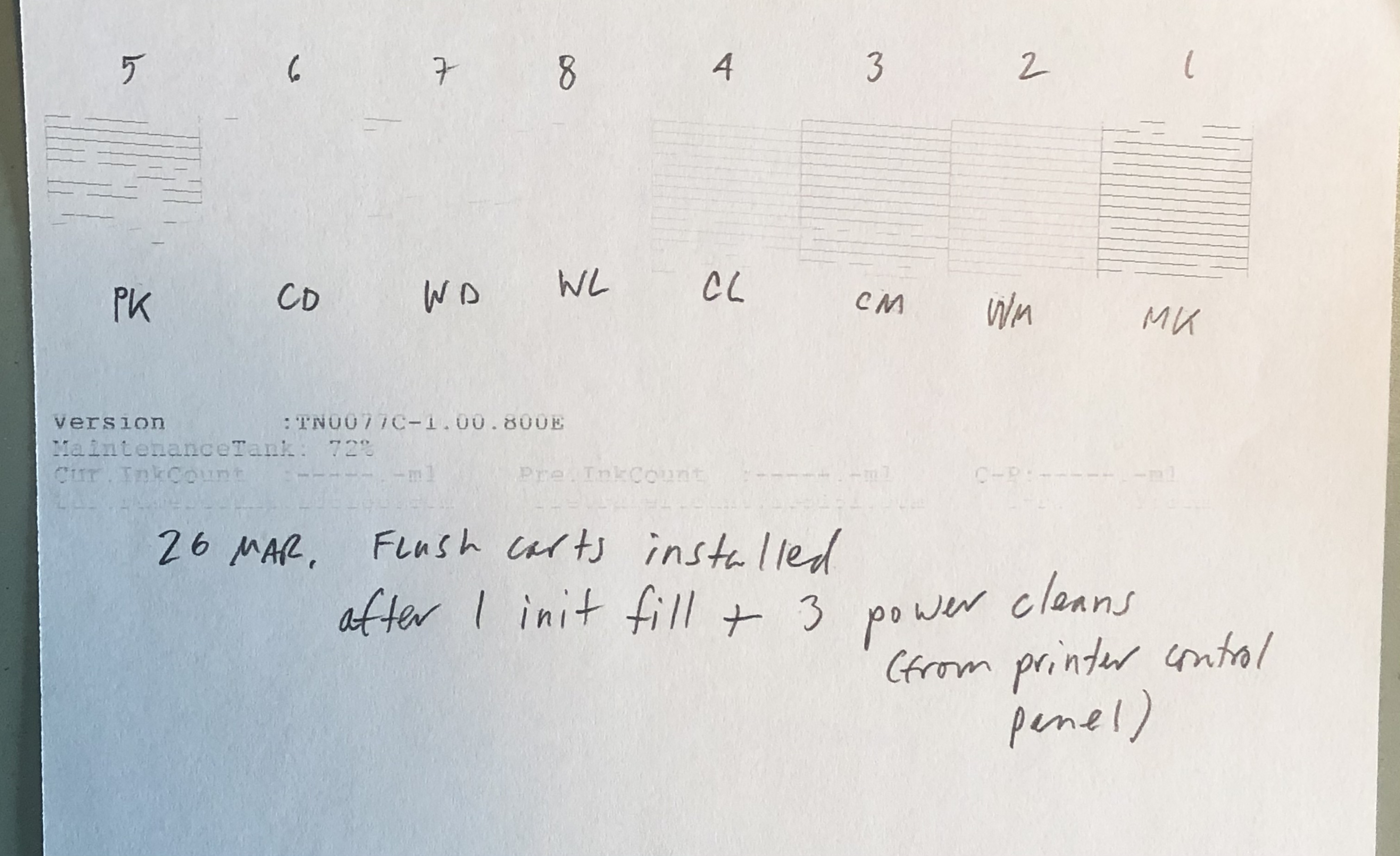

26 March update.

Here is the status on my 7880 saga: all 8 dampers have been changed, new flushing box, new cleaning assembly (complete unit).

I was still seeing incomplete nozzle checks and non-uniform coverage on the capping station. I have verified ink is flowing through the capping station (both tubes without any leaks) as well as the flushing box (and the flushing box is uniformly covered with ink).

I have installed flush filled cartridges on all 8 channels.

Also note prior I was running Pro inks. And I had remapped the LLK channel (slot 1) to run Pro MK ink.

I have run 1 initial fill and 3 power cleans (from the printer control panel). Here is the nozzle check. I am just starting to see pink flush only on slot 2, pro WM ink.

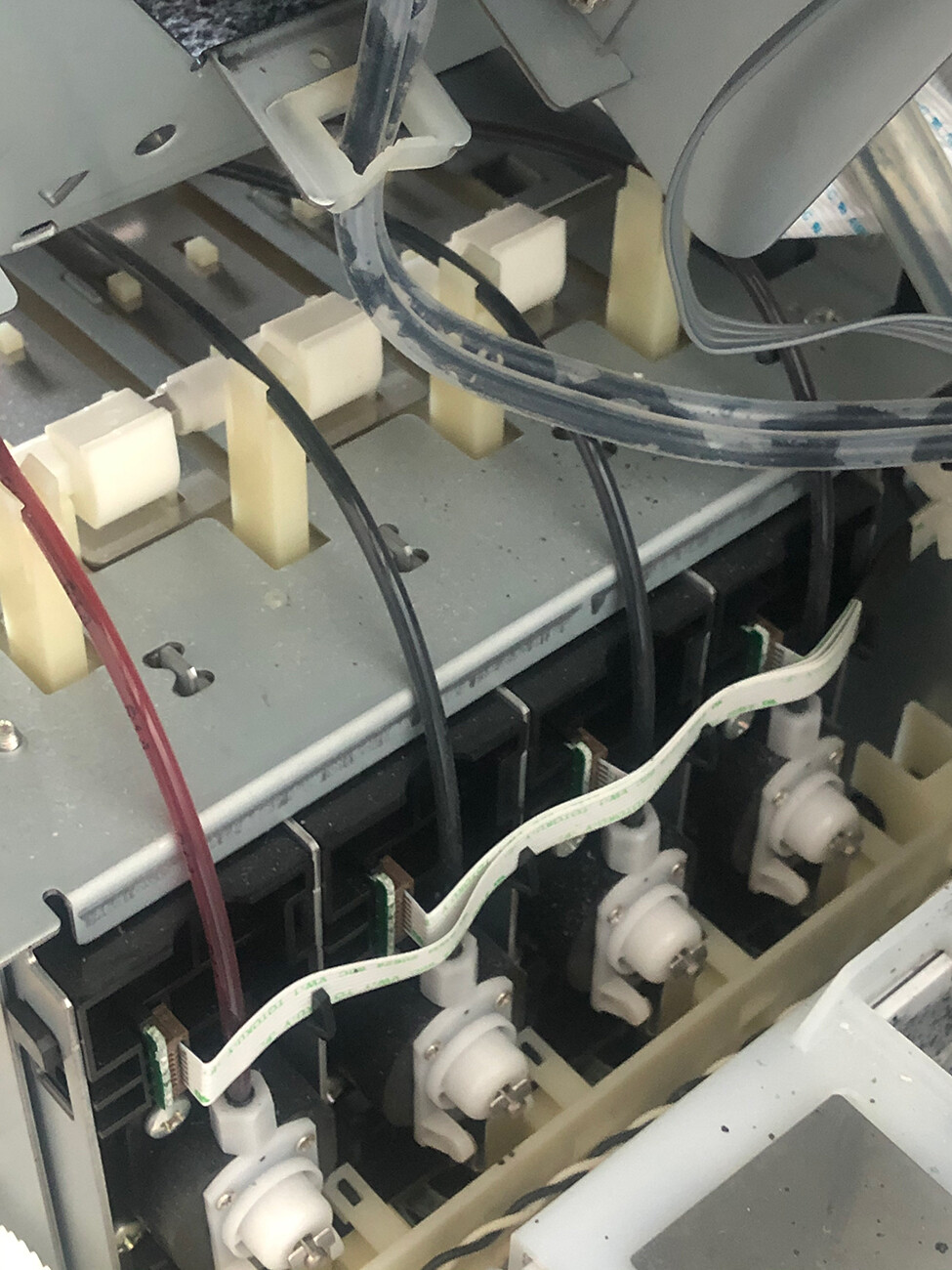

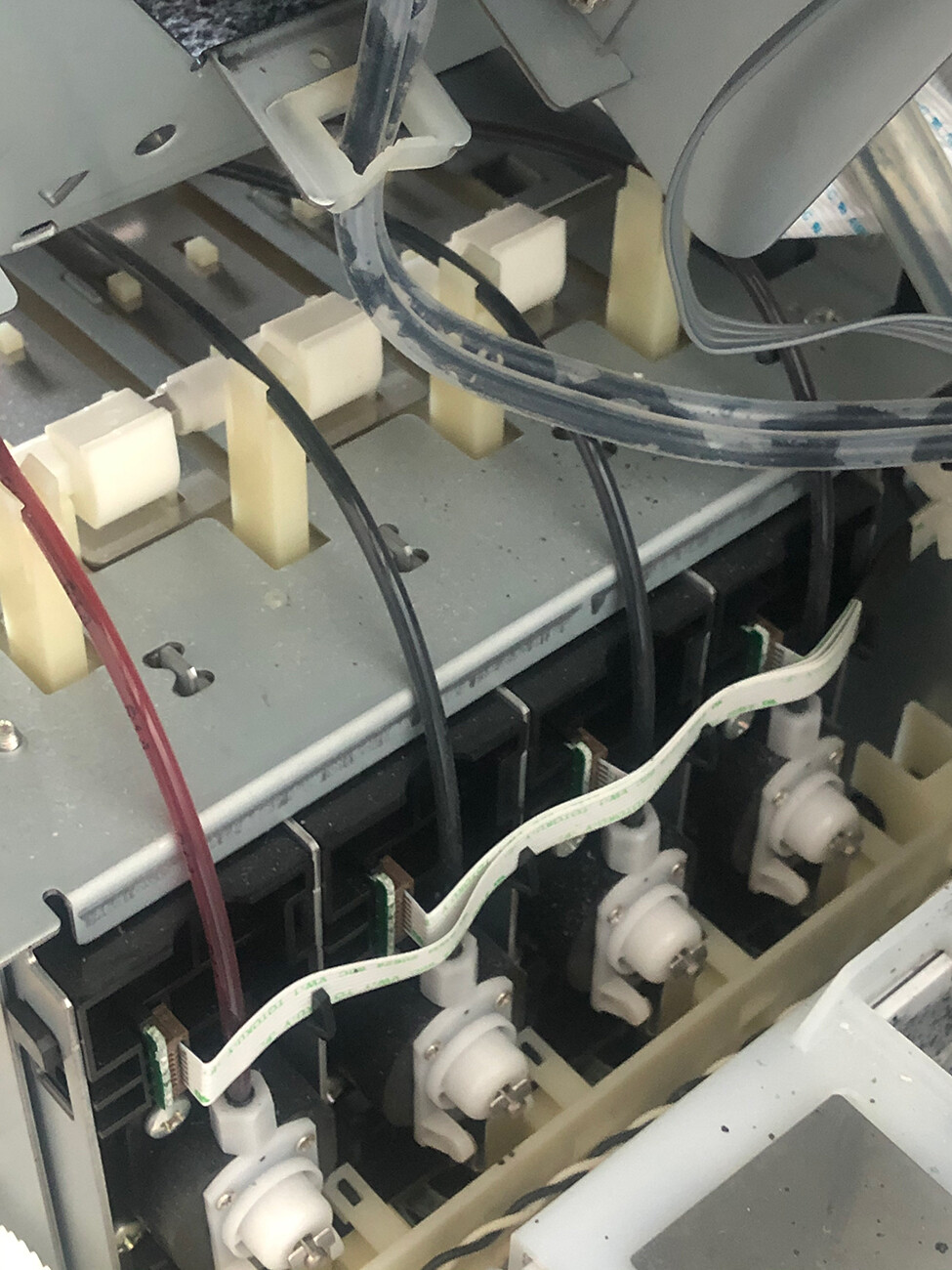

Also here are photos showing the ink lines after running the above init fill and power cleans. The two photos show the ink lines essentially as they exit the carts.

In this first photo, the left ink bay, the black tube at the upper left is slot 1, previously filled with Pro MK.

This next photo is the rear of the right ink bay. The three black ink lines from the top right to bottom left are slots 5, 6, and 7 respectively with Pro PK, CD, and WD inks.

Note that these are the four darkest ink types.

So here are my theories:

-

what I am seeing is ink staining in the four lines due to these being the four darkest inks. However, this would not account for the CD and WD being almost non-existent. It may account for MK in slot 1 as that nozzle check is getting better.

-

Damper nuts too tight causing ink restriction? However, I did previously see better nozzle checks.

-

Failing air pressure pump? However I am not getting any error service codes on the printer control panel.

Any ideas for next steps?

thanks!

Michael

Hi Michael,

Did you ever resolve your issue, if so what was the culprit?

Thanks

Andreas

Hi Andreas,

Short answer is no. Longer answer… I believe part of the problem was the air pressure pump. When we opened it we discovered it was pretty much filled with congealed ink; and we saw ink droplets in the lines between the air pressure pump and the carts. Subsequently in reading about these types of issues it seems as if the carts need to be filled at least half way, or more, so that you eliminate as much air in the system. The carts were the older chambered style (not the newer bag within style). I did hold the carts securely in place by wedging a piece of cardboard under the bottom. It is sad because the 7880 was a great printer. And now I am without a printer. I have yet to decide on replacing it with either a SureColor P6K or P7K.

!

!