Good Day Dana!

Found problem

I seem to have found the ‘lightness’ problem I had during a Nozzle Check with my Epson 7800 printer.

The problem seems to be coming from a faulty one-way check valve in one of the carts I purchased.

The faulty check valve had leaked fluid through the valve and down through the air vent passage way preventing air to pressurize the cart.

Since the cart could not build pressure, the ink - or in this case PiezoFlush could not be pushed out of the cart with the correct amount of fluid to produce a full Nozzle Check pattern.

So, the lack of pressure caused the ‘lightness’.

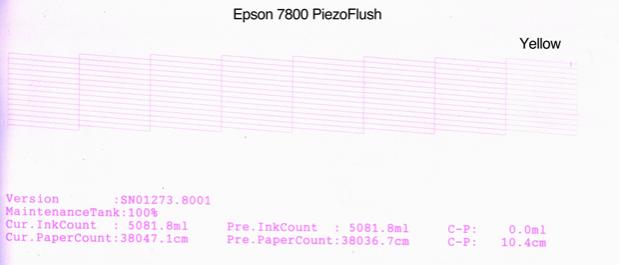

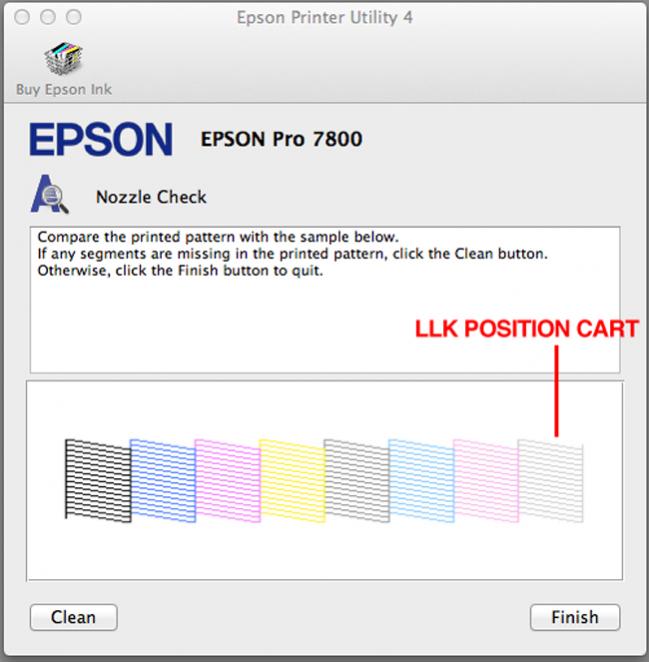

Ink Cartridge position & Nozzle Check ink color position - Layout not the same

Correcting the ink color position on the Nozzle Check pattern… I’m having the ‘lightness’ problem with the LLK [Light Light Black] position not Y [Yellow].

Because I’m using PiezoFlush pink solution in all ink positions, I made an error in thinking the ink cartridge positions were in the same color order as the Nozzle Check pattern ink color order, I thought there was a direct correlation between Nozzle Check pattern ink placement with ink cartridge placement - sharing identical ink positions on paper and ink cartridge positions installed in the printer… But I was mistaken.

Epson 7800 printer cartridge placement: Left to right, LK, LM, LC, LK, PK(MK), C, M, Y.

Epson 7800 printer Nozzle Check pattern prints: Left to right, PK(MK), C, M, Y, LK, LC, LM, LLK

Indicated by the Epson Printer Utility….

oops! :rolleyes:

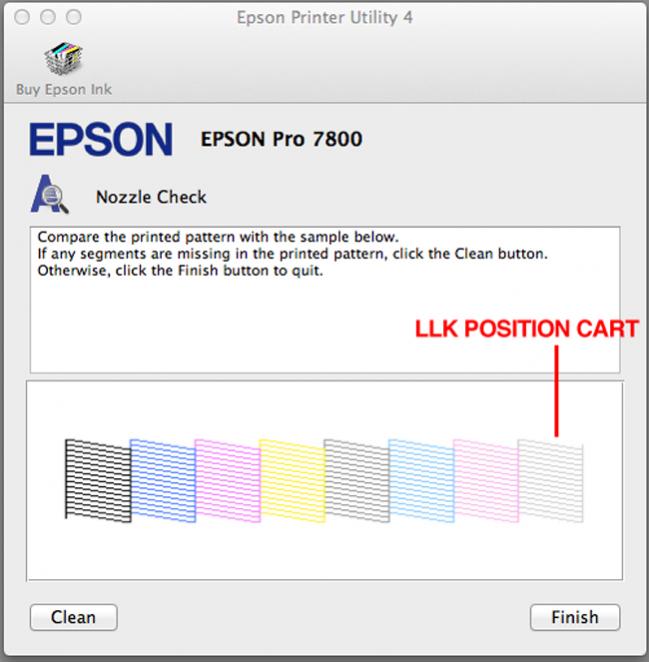

After realizing that it was the LLK position cart, I thought of running one Nozzle Check pattern to see if anything would change.

When I initially (first time) filled the cart with PiezoFlush, I was aware that PiezoFlush had leaked a little in the air vent but thought it would not affect the correct function of the cart as it looked to be a little amount.

This was the reason I had checked to see if that blockage in the air vent was the cause of the ‘lightness’ in the Nozzle Check pattern.

Still ‘lightness’ was occurring.

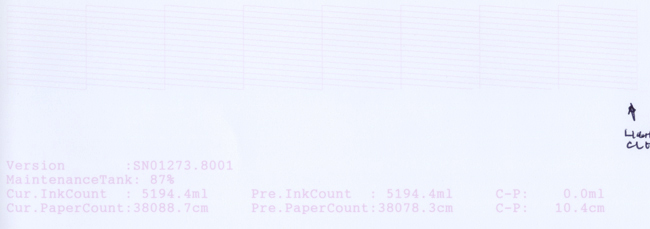

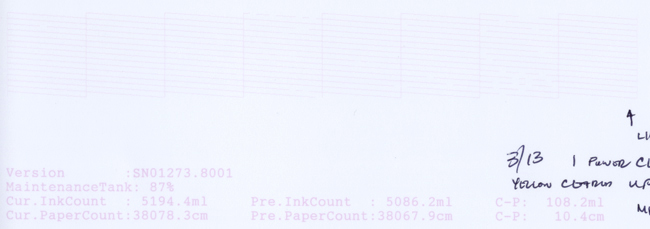

Photo below:

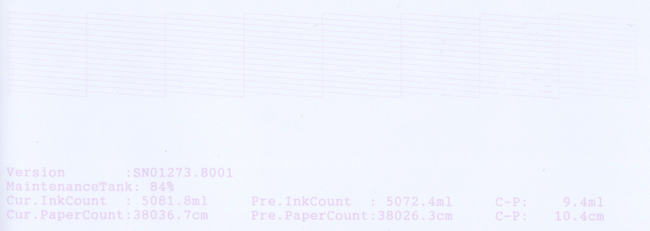

I ran three more tests (this post can only upload 5 photos so I didn’t include the other tests I ran in between).

I changed the LLK cart (Clogged air vent) with an MK cart (Clear air vent) by swapping chips.

Ran one Power Clean.

Problem went away!!!

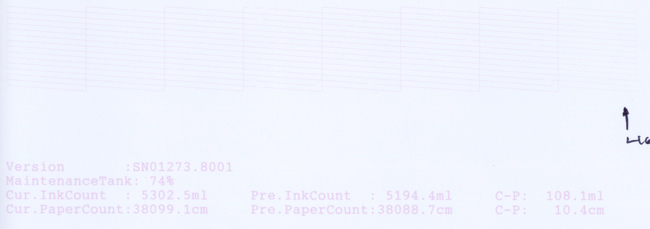

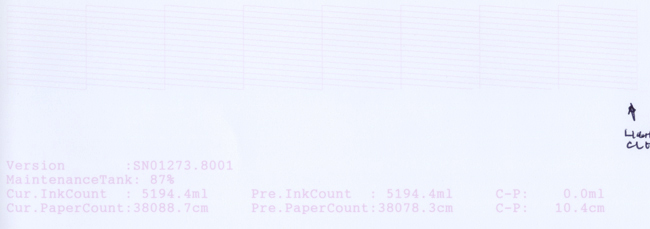

Photo below:

Checked to see if problem was gone by printing another nozzle check pattern and checked for any signs of ‘lightness’.

No problems with ‘lightness’.

Photo below:

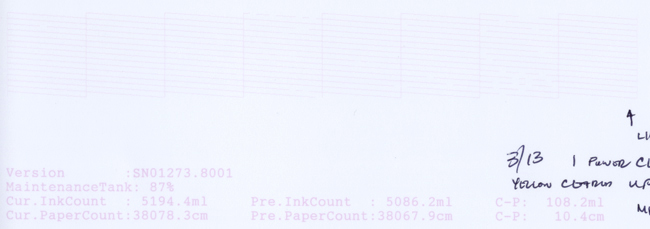

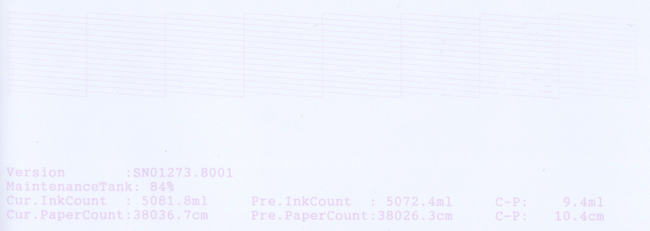

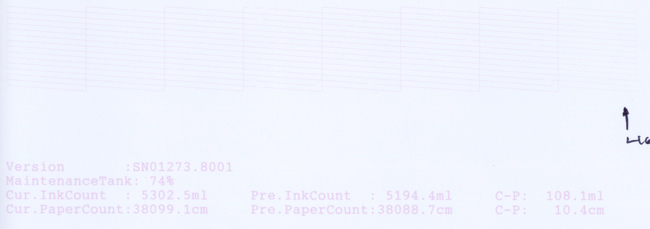

Reconfirmed the suspected cart - Reinstalled original LLK (Clogged air vent) and problem came back with one Power Clean cycle.

Signs of ‘lightness’ showing.

Photo below:

Although I rooted out the problem to a defective cart, I ordered dampers and will change them as preventative maintenance.

Kind regards, Carl