Hi Keith~

Sorry for the delayed response, I was stranded without my laptop for about a week after it suddenly crashed, but luckily got it fixed and am back to my normal schedule.

It is ok to gently/slowly draw ink from the exit hole of the damper to pull ink thru the line and damper to check flow/restriction, though applying too much pressure to push fluid thru the line/damper could cause damage to the damper membrane. I always prime a new damper with ink by gently drawing ink thru the line to fill the damper with ink before reconnecting it to the print head.

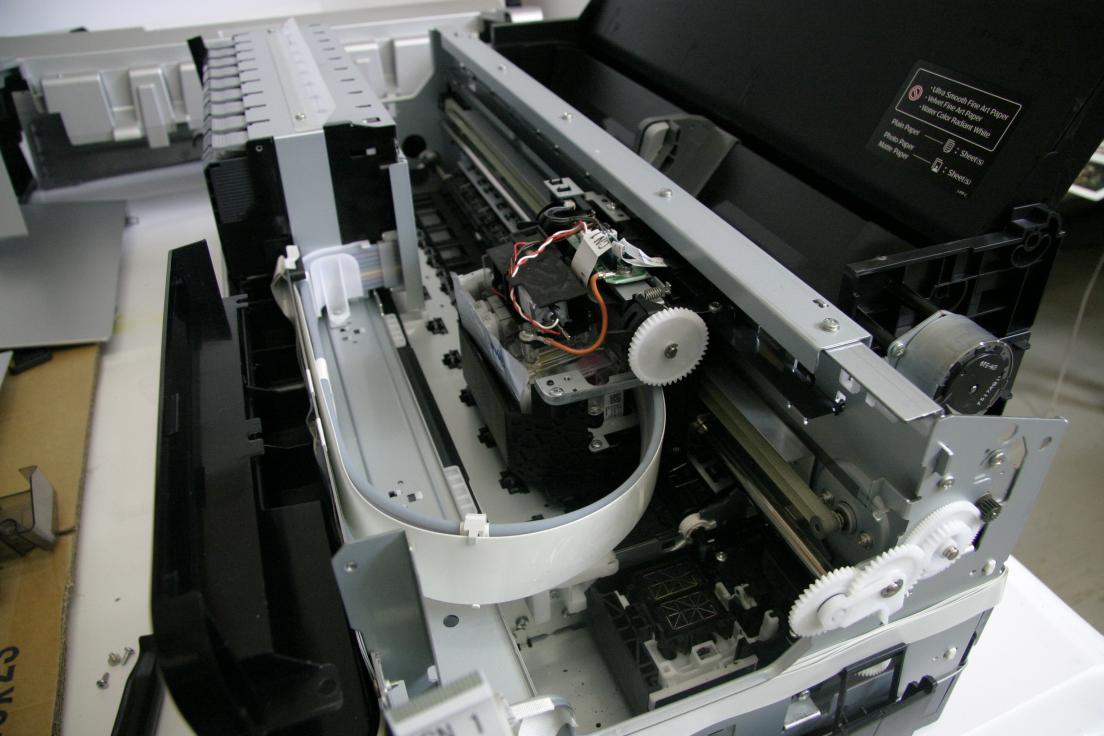

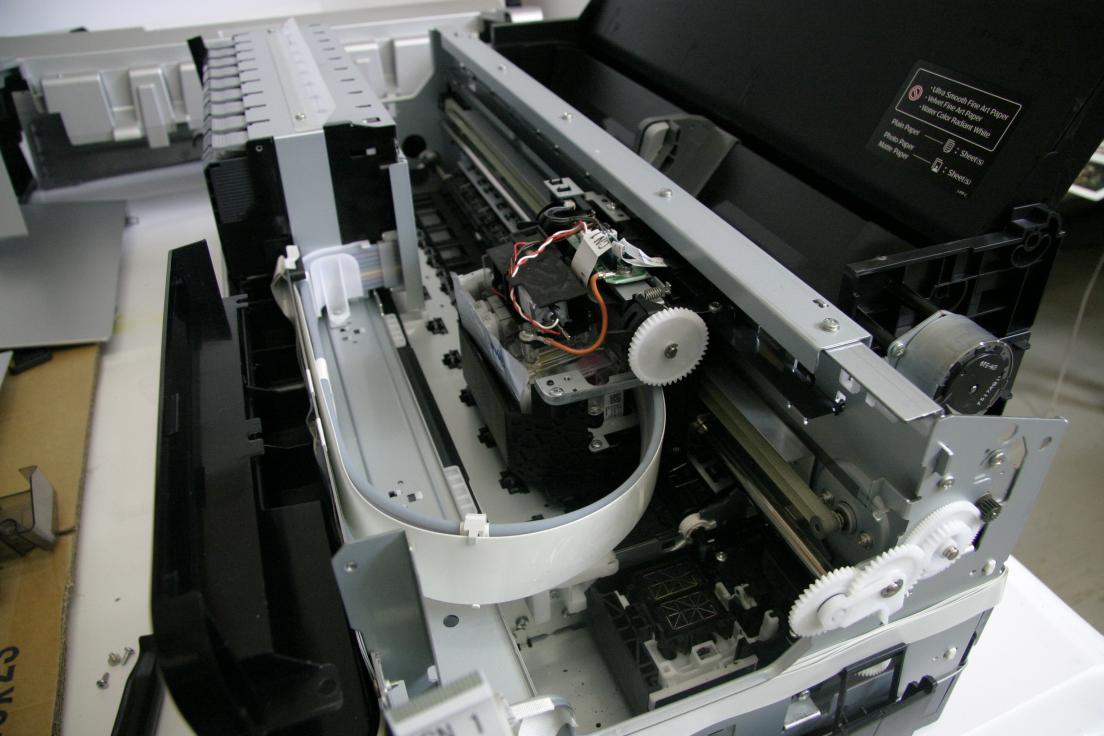

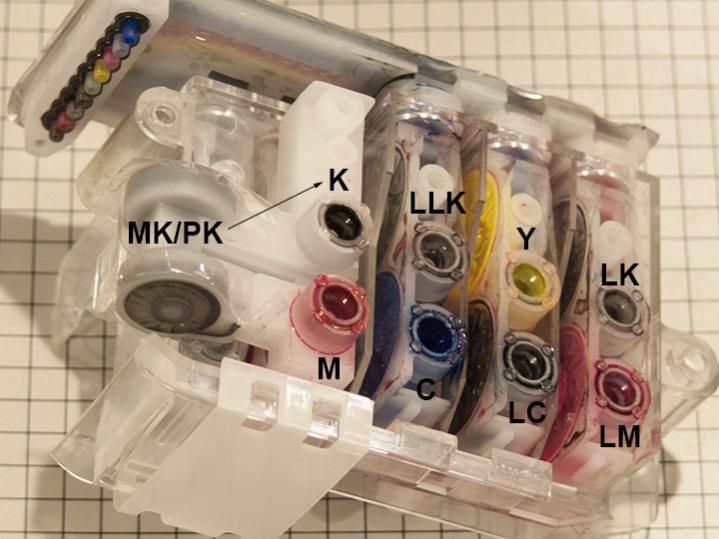

I haven’t personally needed to replace any dampers in our 3800 or 3880 printers yet (they’ve been working great since day one!), though have looked into it and discovered the repair manual instructs to replace the entire ink system, consisting of the cartridge bay, ink lines and damper assembly all as one unit. We do, however, have individual dampers for the 38XX printers that we purchased from the same company we get other model dampers from… Based on my experience dismantling our 3800 a few years ago (I was curious about the new technology), I’m not quite sure if the dampers can be removed/replaced in the assembly unit, or if they’re somehow fused together (I would have to take it apart again to check this).

Below are two photos I took while dismantling and investigating our 3800 years ago, so you can better see the ink system and damper assembly.

Based on the details you provided, I suspect you are experiencing flow restriction after installing the old refill cart that wasn’t allowing ink to flow, and that either coincidentally caused blockage of the LC damper and/or thin labyrinth that connects the ink lines to the dampers (thin metal sheet attached to the front side of the damper assembly), or something to do with air or particles in the line is preventing flow thru that channel…

Our 3800 and 3880 have been working well since day one, so I haven’t had the need to replace parts or do any major cleaning procedures, but have received feedback from other 3800/3880 users who were fighting with stubborn clogs (many with Epson inks who contact us for help cleaning their printers). Several of these people reported they have successfully un-blocked stubborn clogged channels by either forcing PiezoFlush or warm distilled water thru the ink line and damper from the cartridge end, drawing fluid thru the line from the damper end, and/or disconnecting dampers from the print head, then using our print head cleaning kit to flush the micro-channels of the head (we don’t suggest people dismantle their printers or force fluid thru the lines, but they did it on their own, had success, and happily told us what they did to fix their own printers).

Since we last communicated, have you done anything further with the printer in attempt to get the LC printing again? If so, what have you done?

Please let me know so I can try to help get your LC printing well again, thanks- Dana