In a couple of recent threads (here and here) I discussed issues I was having with my existing printers and debated purchasing a new R3000 or a second hand R2880. I bought an R2880.

SUMMARY: However I am having a lot of trouble getting and keeping good nozzle checks. I have done the Dana C cleaning routine a couple of times, and still there are issues. I’ll provide a little more detail below. My question is: are there other areas that perhaps I should clean? For example, there is a wiping station on the right side of the printer - is it possible that this needs cleaning as well?

DETAIL: Now the history. I bought this R2880 printer from some distance. I don’t know a lot about its history, but it had the appearance of being in good condition and the WicReset too reports that it hasn’t been used a lot. Ink waste counters are under 20%. I was provided with a good nozzle check pattern in advance, and I did a check when I got it and it was fine. It may have not had much use in the last several months, but despite this the nozzle pattern was good. A few days after I got the printer my new ConeColor K3 Vivid inks and new refillable carts arrived.

Given the clean nozzle check I didn’t initially do a full Dana C clean, I only cleaned the capping station and wiper blade. With the fresh ConeColor refillables installed I initially struggled to get a perfect nozzle check [long story omitted here] but finally had good results. However within a day or so I was again getting a lot of gaps in nozzle checks and bleeding between colours. Eventually I found that one cart (magenta) had drained!

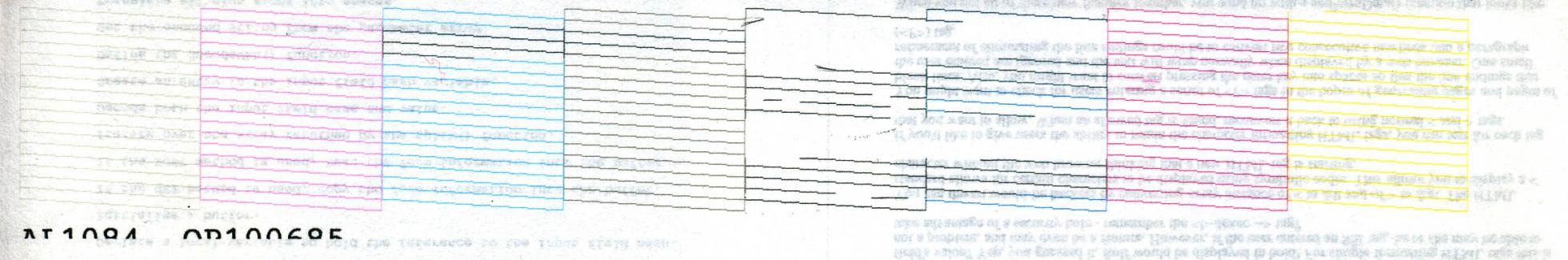

So I did a full Dana C cleaning routine - capping station, wiper blade, ink nipples, special printer head cleaning cartridge & syringe, and under the head. I also filled some refillables with flush and installed them for a few hours. Then I topped up the ConeColor carts and installed them. After I printed out the pink flush from the weaker colours again I was able to print for a day or so, with the odd missing nozzle now and again, but then I started getting gaps in the nozzle check pattern and colour bleeding. See the nozzle check pattern attached. At least no cartridge drained this time.

At this stage I started to lose confidence. My only idea was that perhaps I didn’t do the full clean sufficiently well. So I have done it again, this time using a lot of flush in the process. There’s definitely no sign of any pigment ink anywhere in the areas cleaned. It has sat for a day or so with cleaning carts and tomorrow I will put the ConeColor carts back in. But I am fearful of the process repeating itself and then what do I do? Go back to OEM?

So my question is: is it possible that the cleaned print head could be picking up gunk from the right-side wiping station, i.e. the opposite side to the capping station? I assume you know what I mean. This is the area where the print head seems to stop to wipe itself during a head clean, and other times as well I think. I know it’s possible in theory, but have you seen this in practice? Any tips on cleaning it?

I also have an R1900 with piezography inks - pretty much the same printer as I understand it - and it’s working well with your refillable carts. So I know that the system can work. I compared the two printers, and I would have said that the R1900 was also a little messy on the right hand side wiping station, and that doesn’t seem to be affecting things in that printer. Comparing parts in the two printers doesn’t suggest anything faulty in the R2880 that the naked eye can see. The R2880 has more ink on the “Front paper guide pad” (service manual terminology) in the areas away from the right side cleaning station, but I can’t see what effect that would have.

Sorry for the long post. I’m running short of ideas. Help …