On the Piezography 2 Matte and Gloss for K3 printer models page there is the following statement: “Piezography 2 is NOT available for non-K3 models, including the 1400/1430, 2200, R1800/R800, R1900, R2000, or 7600/9600”. This has always disappointed me. I’ve never really been convinced about the value of shade 7, and as stated in another post today I find the MK/PK swap unnecessarily wasteful, given the associated head cleans.

Now I can’t speak for all the other printers, but I have discovered that this is NOT true for the R1900 and therefore I assume not for the R2000 either. These hi-gloss printers are not K3, but they in fact heavily disguised K3 printers. They use the same DX5 printhead as the R2880, from what I can gather, and some of the larger and older printers K3 also use some sort of DX5. The R1900 is virtually identical to the R2880 physically, so it was surprising to me that P2 doesn’t suit the R1900/R2000.

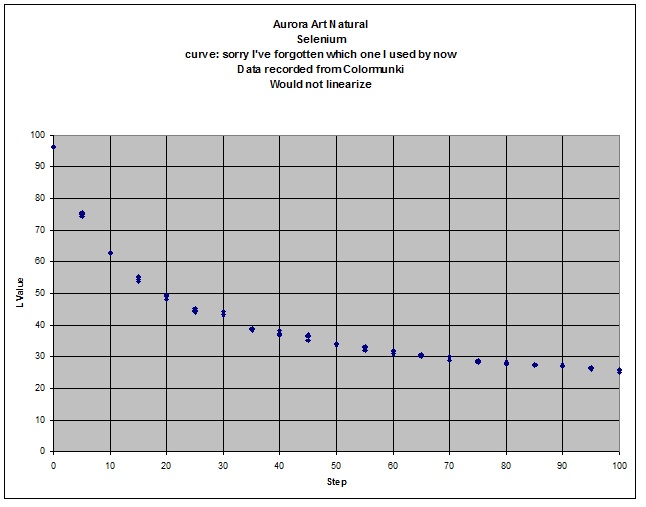

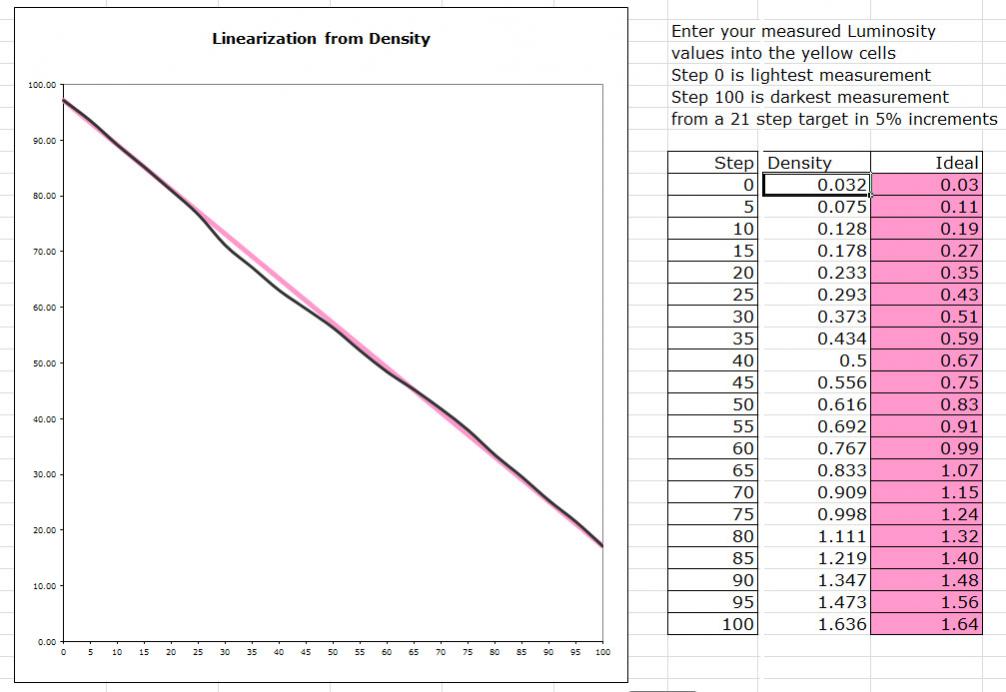

It is true that the piezo QTR curves are different for the R1900 - the shades are in a different order. So as an experiment I remapped the P2 SE x880 curves so that the shades appeared in the correct places in the quad files for the R1900, and checked how linear the result was. Here is the result for HPR:

I have to say that I was staggered. This is better than the standard curve for HPR performs on my 4½ year old 1900, which has a certain amount of drift. Roy’s new droplet pulls it into a straight line. I’ve converted all the eleven available special edition P2 curves, and for those papers that I have, the results are similar, although not quite that good. I’ve also used the HPR curve for EEM, and HPR-Baryta for IGFS, and again got similar results. I’ve also converted all the neutral P2 profiles for Jeff’s new P2000.

It seems to me that P2 IS available for the R1900, once the curves are remapped. I’ve done 40% of then - could IJM do the other 60%?

Why bother? Well, as I said elsewhere, I am far from convinced that shade 7 is necessary for most people, and I have a strong aversion to the waste arising from the MK/PK swap.

There is another side benefit to this discovery. One problem with the R1900/R2000 is that the range of available curves is more limited than for the x880 printers. IJM has been reluctant to create more, as the work wouldn’t be justified for such a niche printer. But this isn’t a problem it seems - the x880 curves can be remapped to the R1900. Problem solved.

I haven’t attached the 22 remapped curves, because it isn’t clear whether IJM would welcome that. But I am happy to if they would, and I’m happy to provide them to anyone on request.

It’s amazing to see how much ink builds up over the course of a printing day without your ever doing a single head cleaning.

It’s amazing to see how much ink builds up over the course of a printing day without your ever doing a single head cleaning.