This post relates to printers that have ink cartridges on the print head - R2400, R2880, R1400, R1410, R1430, R1900, R2000, P400. For these printers it is suggested to print something (at least) once a week in order to keep the pigment in the cartridge suspended. The movement of the head back and forth is supposed to provide sufficient agitation to do this. (Other printers like the R3000, P600, 3880, P800 and larger require an alternative approach.)

My problem has been that it hasn’t been working. If I’m not printing then I’d normally do a nozzle check and print some kind of purge pattern at least once a week. But what I’ve been finding is that despite doing that, after about 4 weeks I’m starting to see a drift in linearity of my curves, and by the 6 week point, I need to do something. Either remove the carts and agitate them or drain and refill.

Roy Harrington has recently released QTR version 2.7.8, and for these printers and a few others has included a 2880 Super resolution (weave) setting. This prints a lot more slowly and takes more passes back and forth to build up the image. More details in the relevant thread:

https://groups.yahoo.com/neo/groups/QuadtoneRIP/conversations/messages/15296

In the process of testing this new setting I found [long story omitted] that printing an entire A4 page uni-directional at 2880 Super did provide enough agitation to restore my curves to linear.

The problem with printing a purge pattern this way is that you could use a lot of ink. It occurred to me that the main objective is to maximise the number of passes back and forth across the page, rather than to push ink through the head. (Which you would want to do on a printer with ink lines and dampers to keep the ink flowing through the lines.)

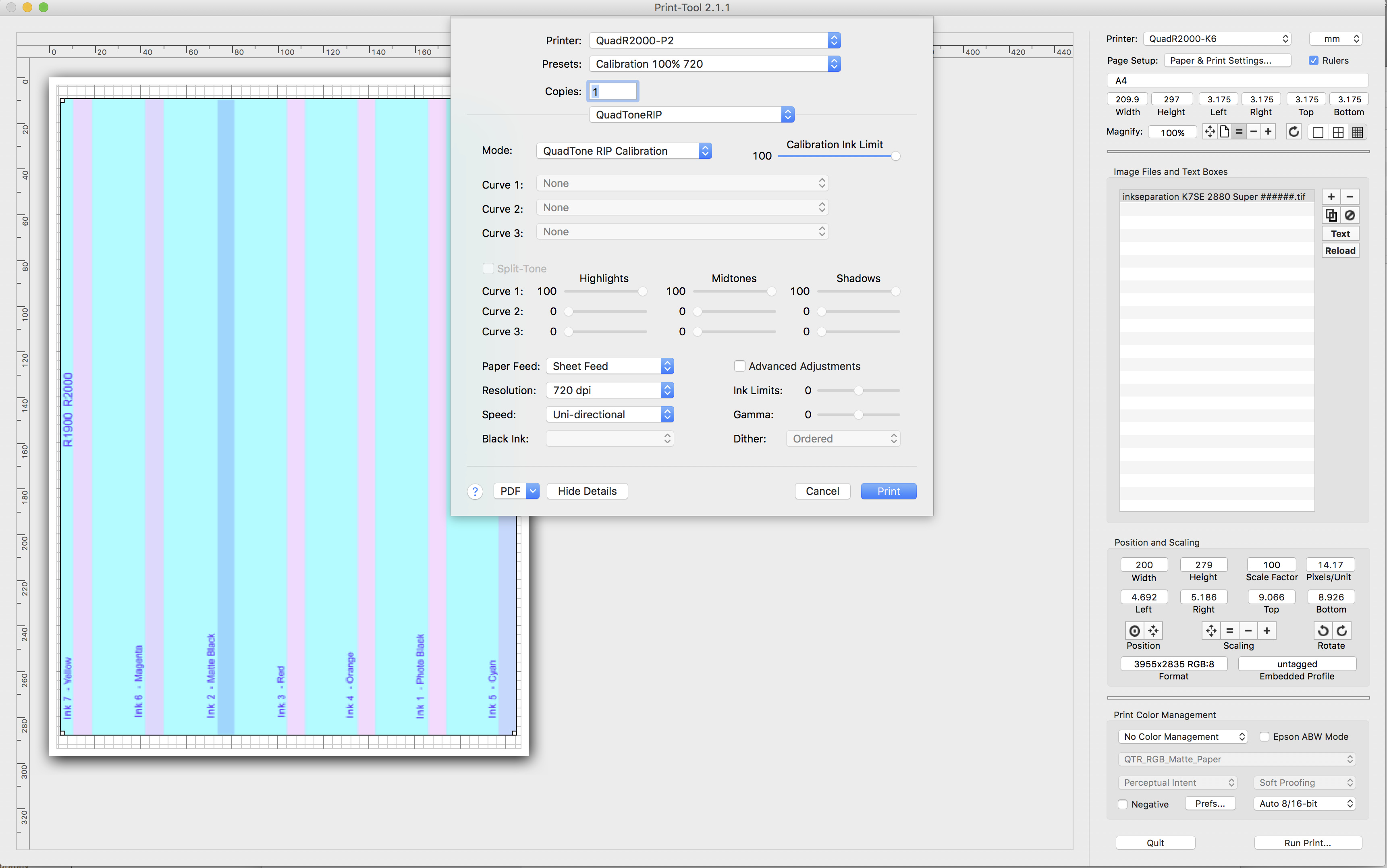

So I designed my own purge pattern. I took the 15% squares from the ink separation page, created some narrow columns spaced across the width of the page, and running the length of the page. Printing this at 2880 Super in calibration mode is mighty slow, but seems to agitate the ink quite well and doesn’t use a ton of ink.

I’ve attached the page I created but most people will need to adapt it. It only contains 7 columns, as I don’t run a purge on GO in the R1900, R2000. You’d need to add a column of (254,217,255) for LLK on a K3 printer. Or remove a column for the R1430. Also the ordering and labelling is intended for the R1900 & R2000, but you’ll get the idea. Also it’s for an A4 page, so readers in non-metric countries will need to resize it for Letter.

Minimal Purge Pattern for R1900 2880-Super.zip (55.9 KB)

p.s. If you print this on an A4 page, you will see some of the infamous first and last inch micro-banding. It’s not really of much consequence for this purpose, and I wanted to use pretty much all of the page to maximise the agitation benefits.