Hi Walker,

I installed the new carts and flush into the two printers, with the following results:

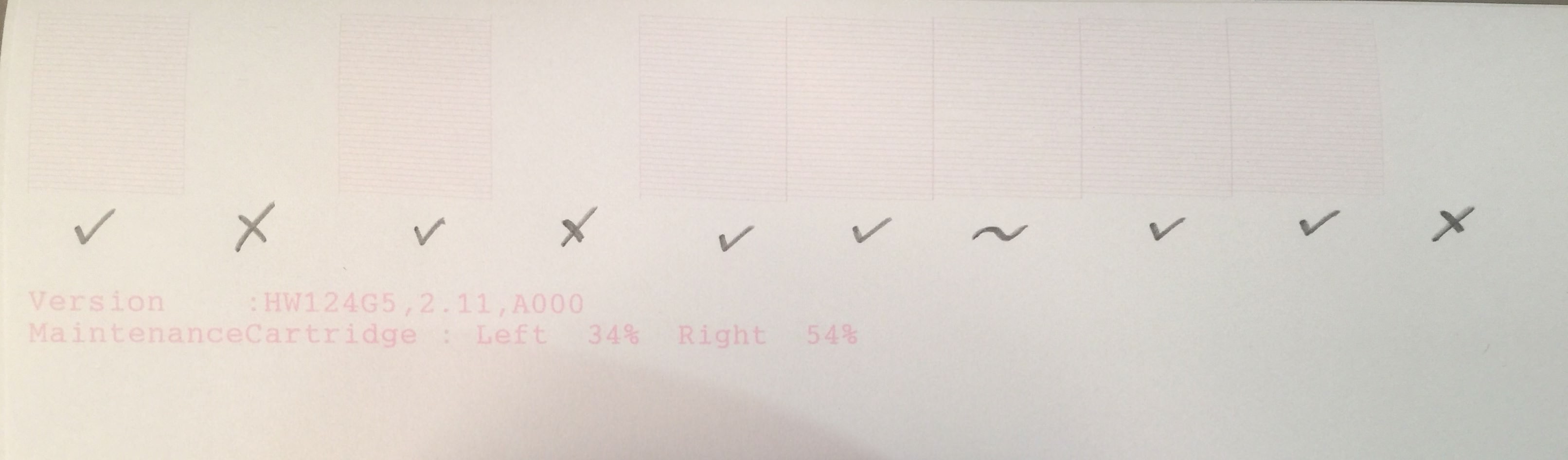

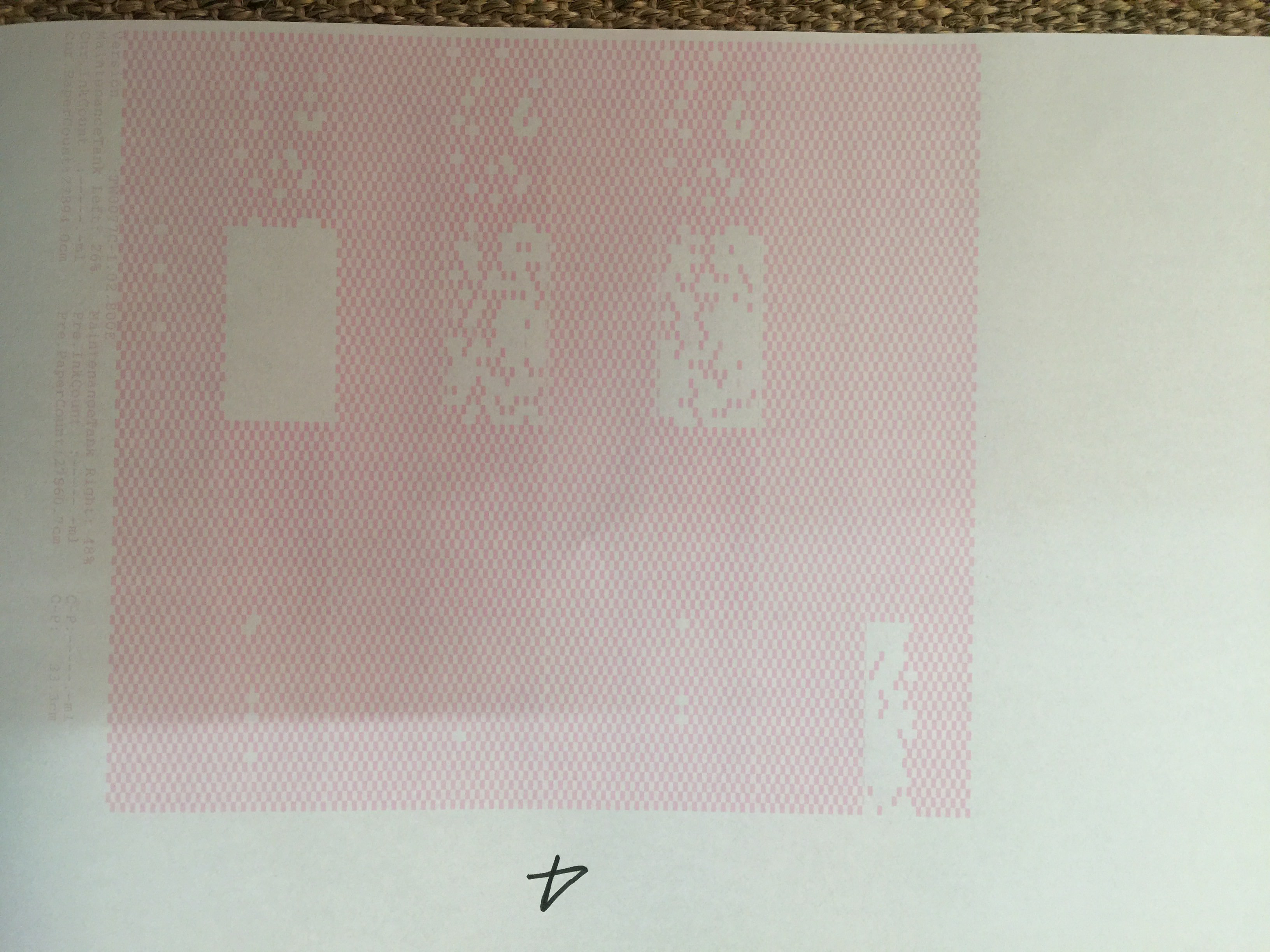

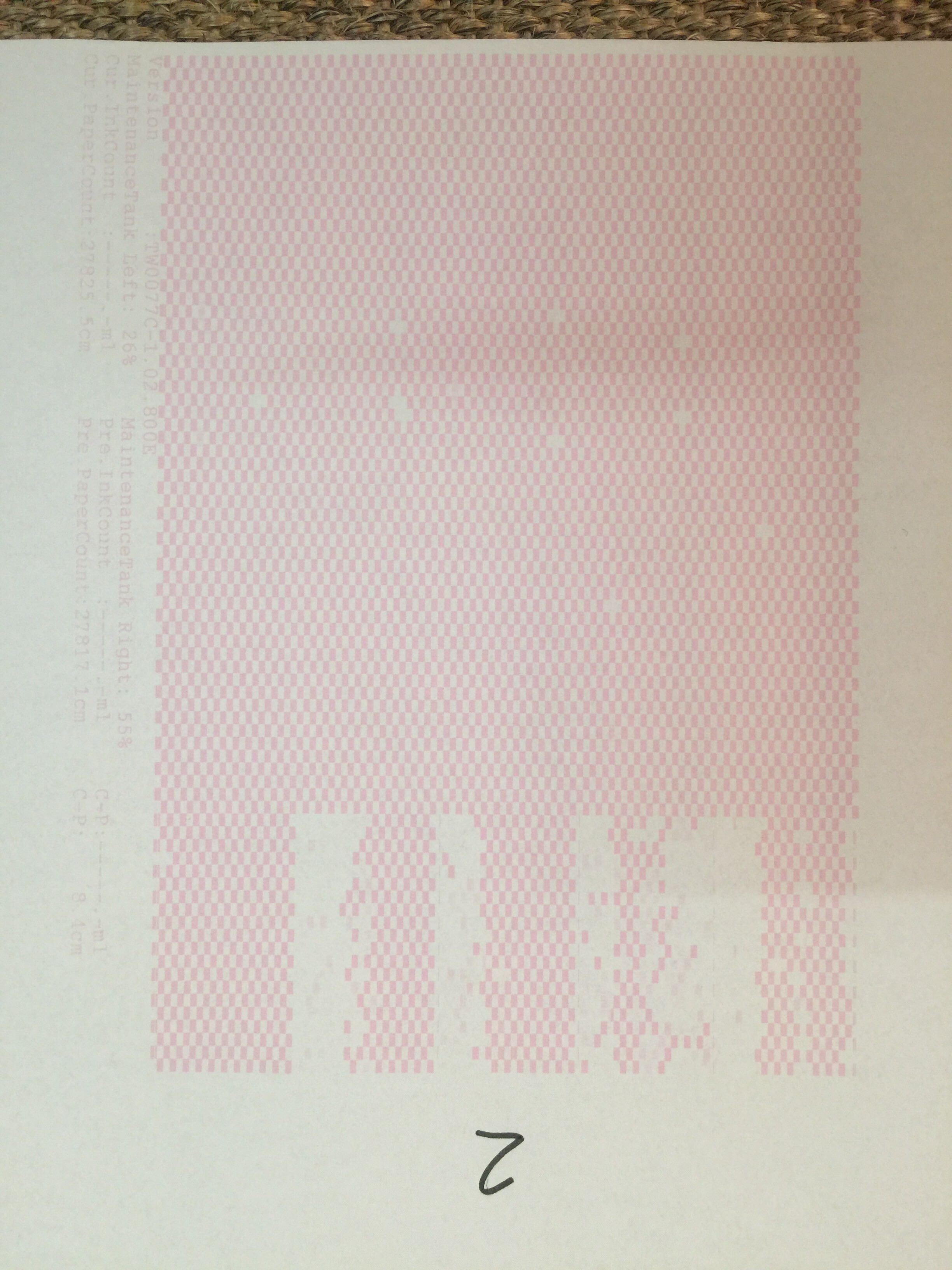

Epson 9900

The two missing colours (100% missing) continue missing.

After the init fill, a third colour has gone completely.

As a result, three colours are totally missing now.

A fourth colour shows a few clogs that seem persistent

The other colours seem right

I have performed the init fill, and a couple of cleaning cycles for the pair that was totally gone. Nothing seems to change.

The two colours totally missing were the ones with the maximum amount of black floaters in the liquid… so I guess it might have clogged the dampers, not allowing ink to get the to head? If that is the case, I suppose that the head has been working “dry” with these colours, and that it might be gone?

I do not know what you would recommend doing now. Do you think that any other cleaning could be done, or should I call the technician to change dampers and head? It was all changed new last summer, with few prints in between and perfect nozzle checks every day since

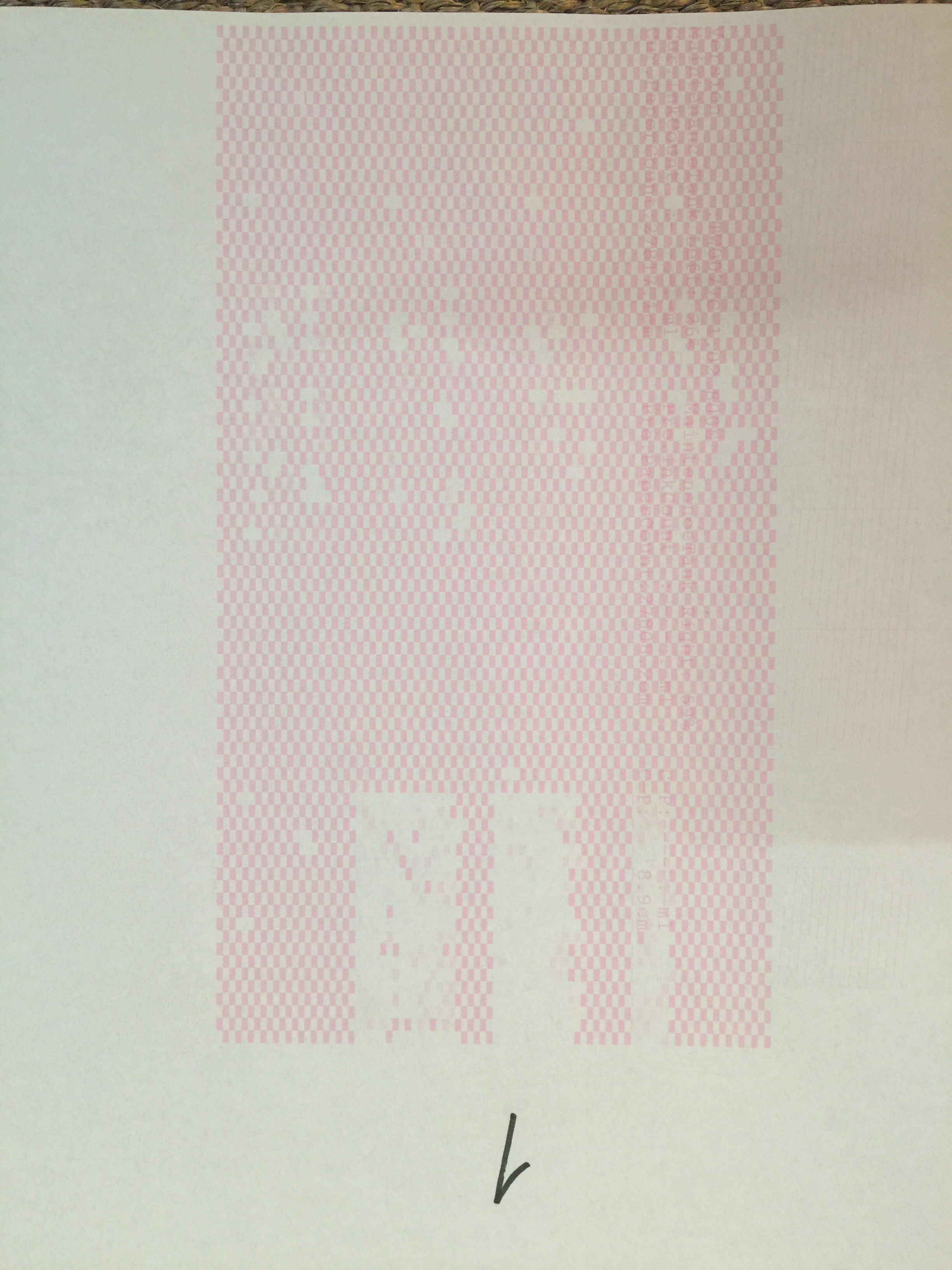

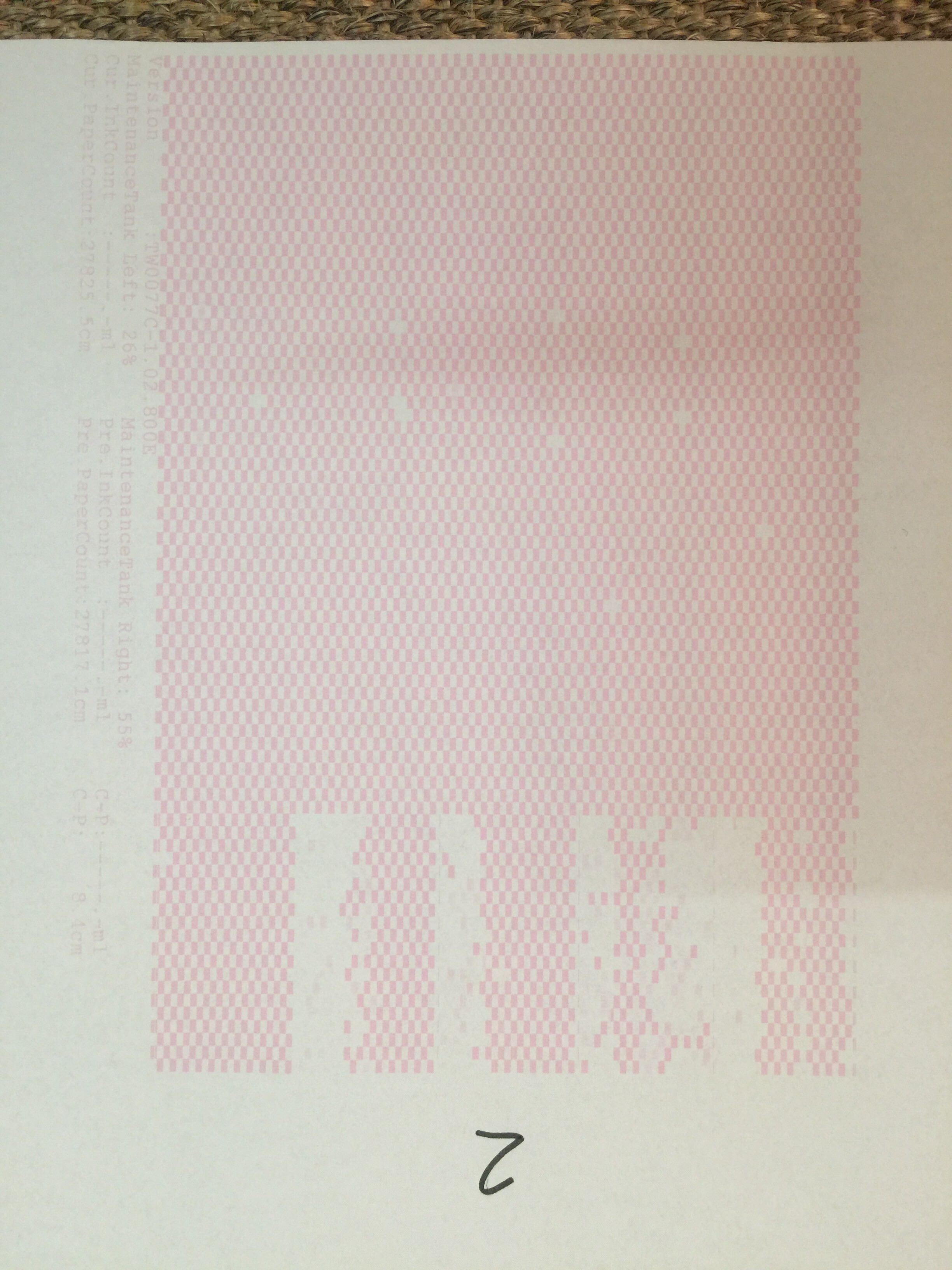

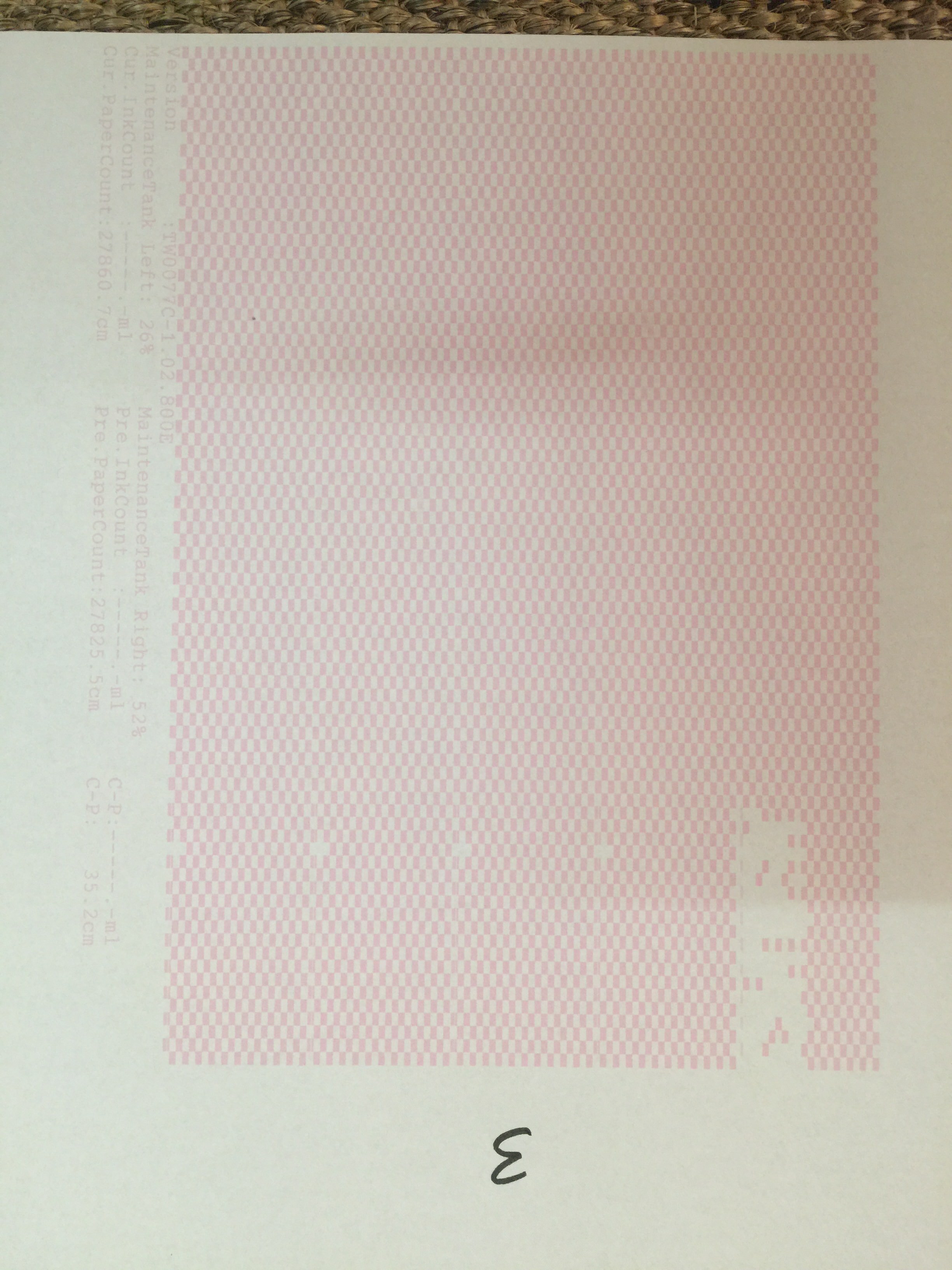

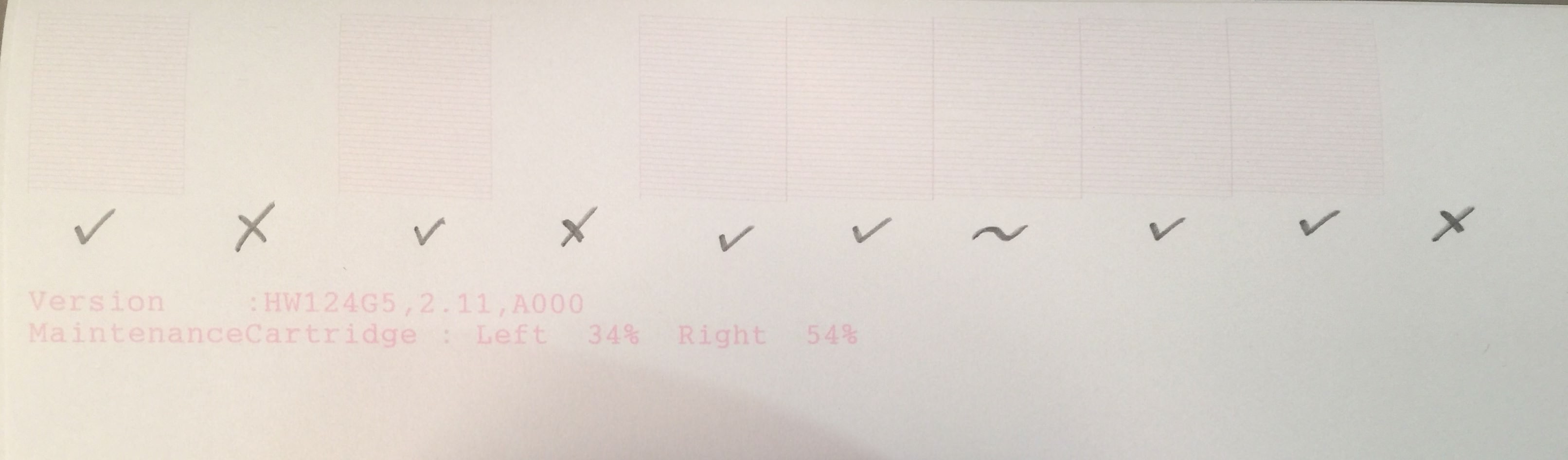

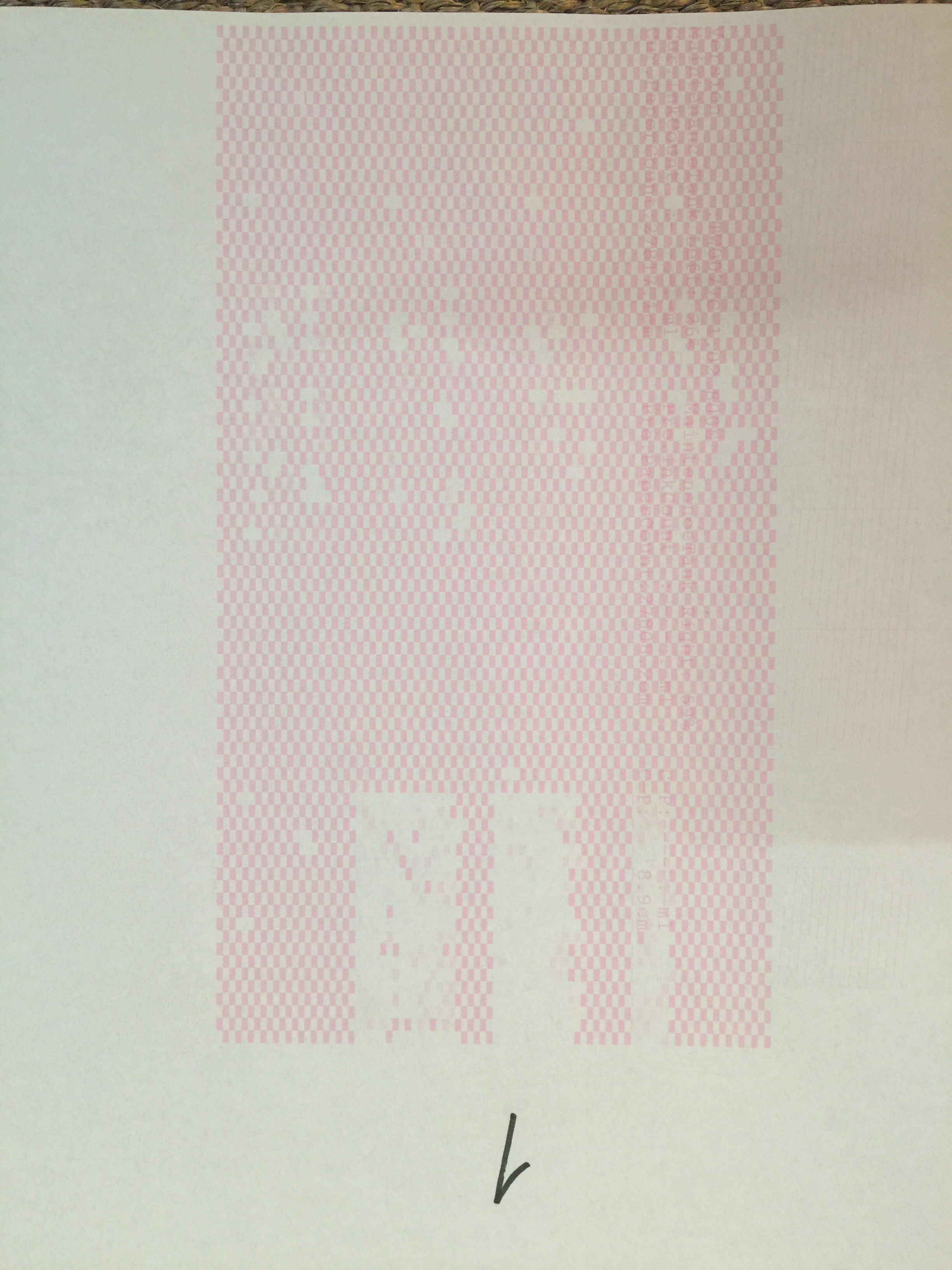

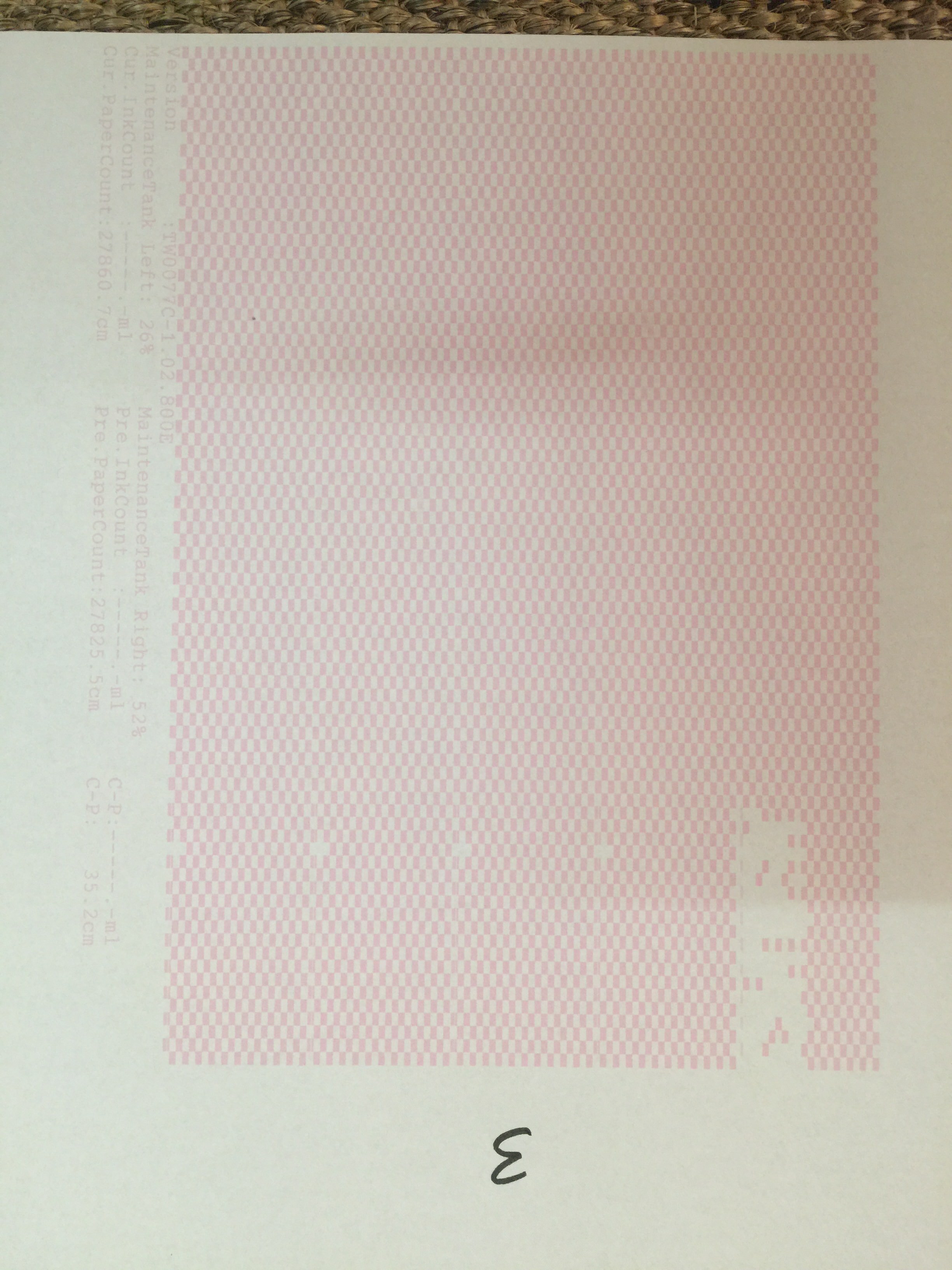

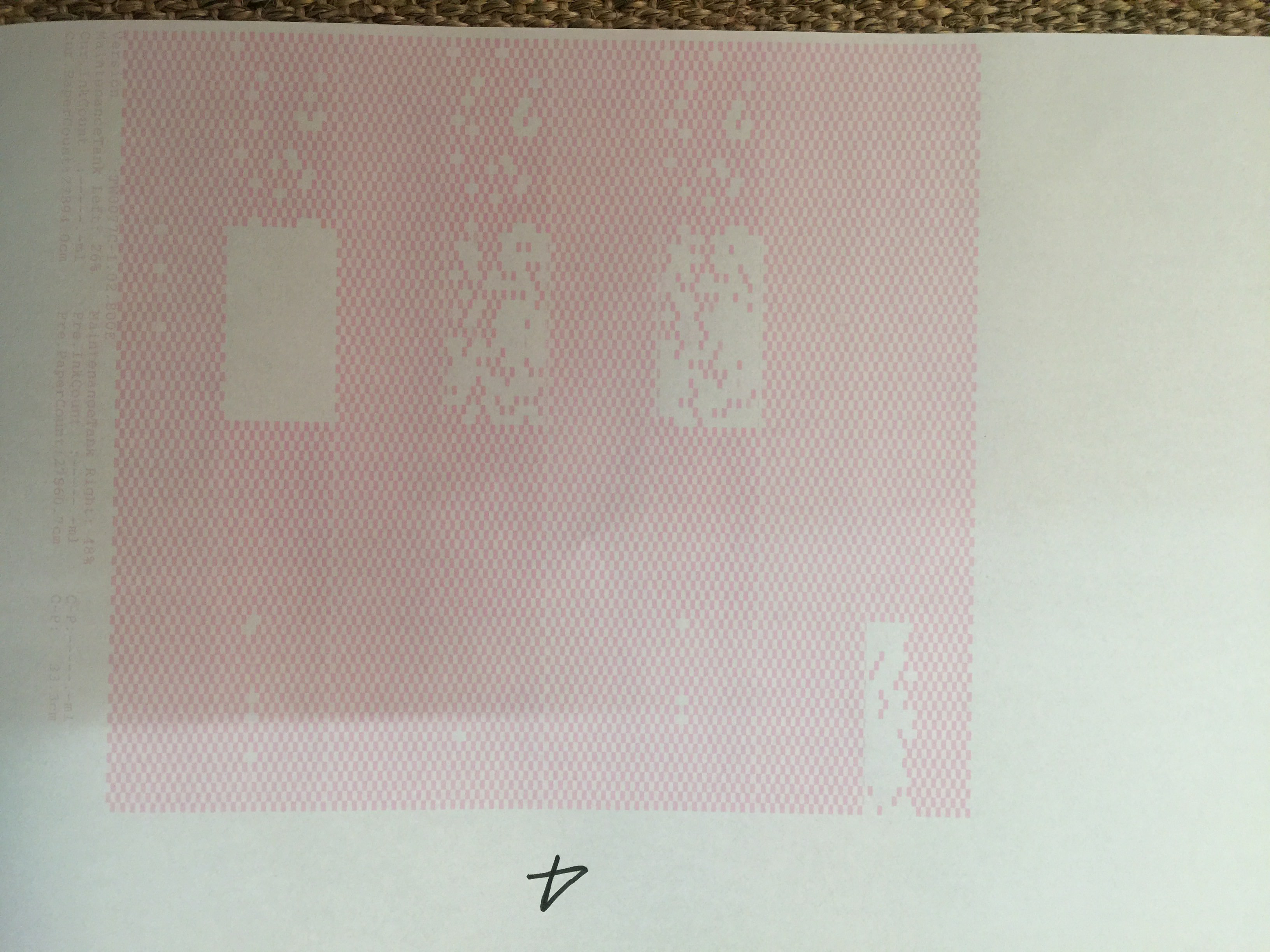

EPSON 9880

I have made the init fill, and realized that when performing the Auto-Cleaning ON + Print nozzle check (you get the mosaic of rectangles being printed) that the clogs are moving. Before this second init fill, one of the colours was totally clogged, now seems ok. However, other colours that were fine, now are clogged. In other words, the clogs seem to jump from one colour to another. I have allowed some time for the printer to sit down, and now I have allowed it to perform a few auto-cleanings, showing some improvement. But yet, the results are not perfect. What would you recommend? Do you think we are here seeing the result of air into the machine, rather than proper clogs? This machine did not have floaters like the 9900, so I am inclined to think about air getting into the machine somehow…

Let me know what to do - how to proceed - what you think…

Am I being out of luck, or is this normal? It seems I spend all my time, money and energy solving printer related problems. For 3 years I have been trying to make platinum prints, but everytime I intend to devote myself to it, the printers go bad and I end up spending more and more grands. This is insane.

Thanks in advance Walker for your help,

Warm regards,

Rafael

PD: Pictures attached of the last nozzle check of the Epson 9900 and the 9880 (there is a series from 1 to 4 showing the clogs jumping from one to another as the printer performs cleaning cycles).